Cold-resistant EPDM (ethylene propylene diene monomer) composite material and preparation method thereof

A composite material and cold-resistant technology, applied in the field of EPDM composite materials and their preparation, can solve problems such as general cold-resistant performance, and achieve the effects of low dynamic heat generation, improved product reliability, and good physical and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

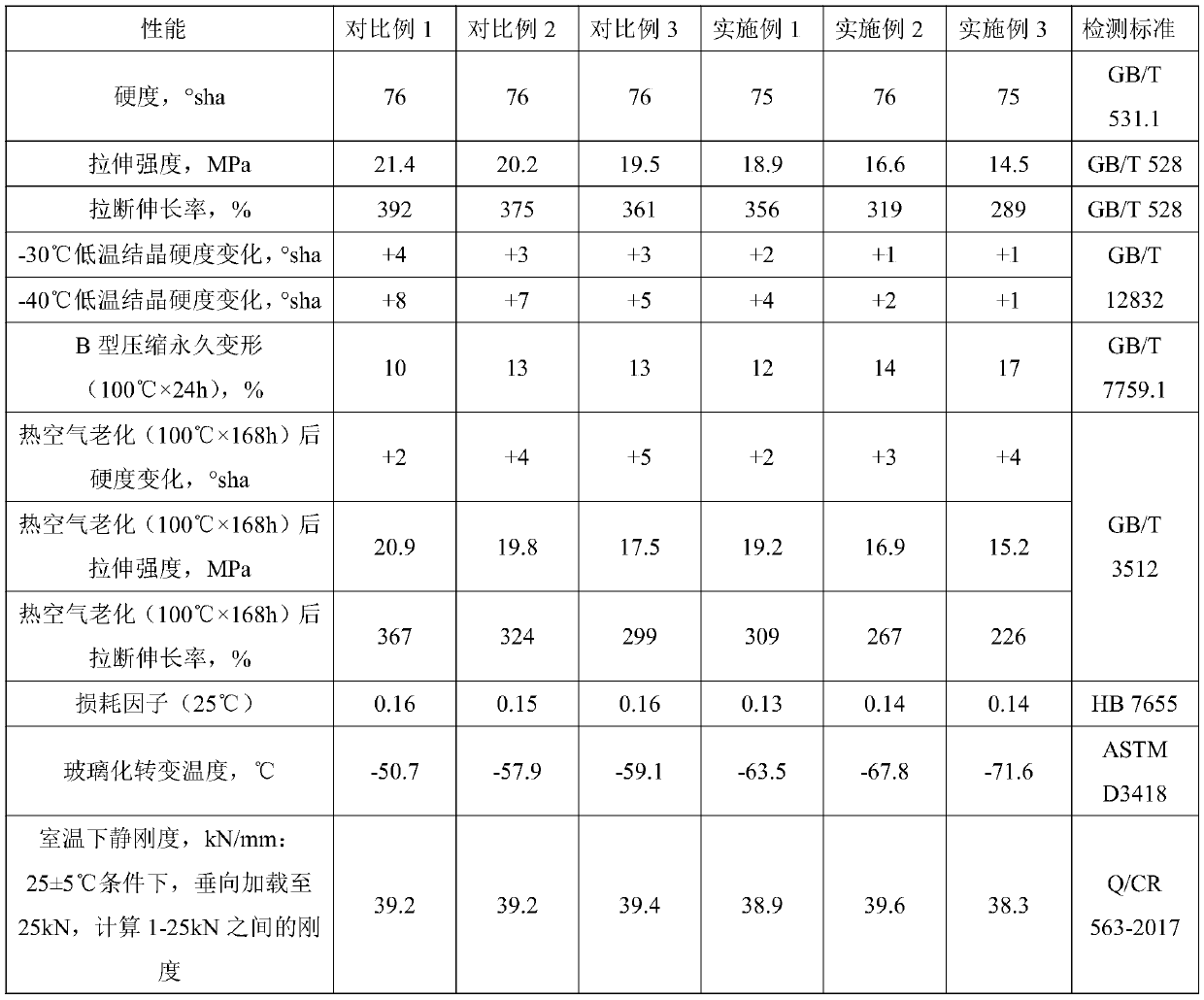

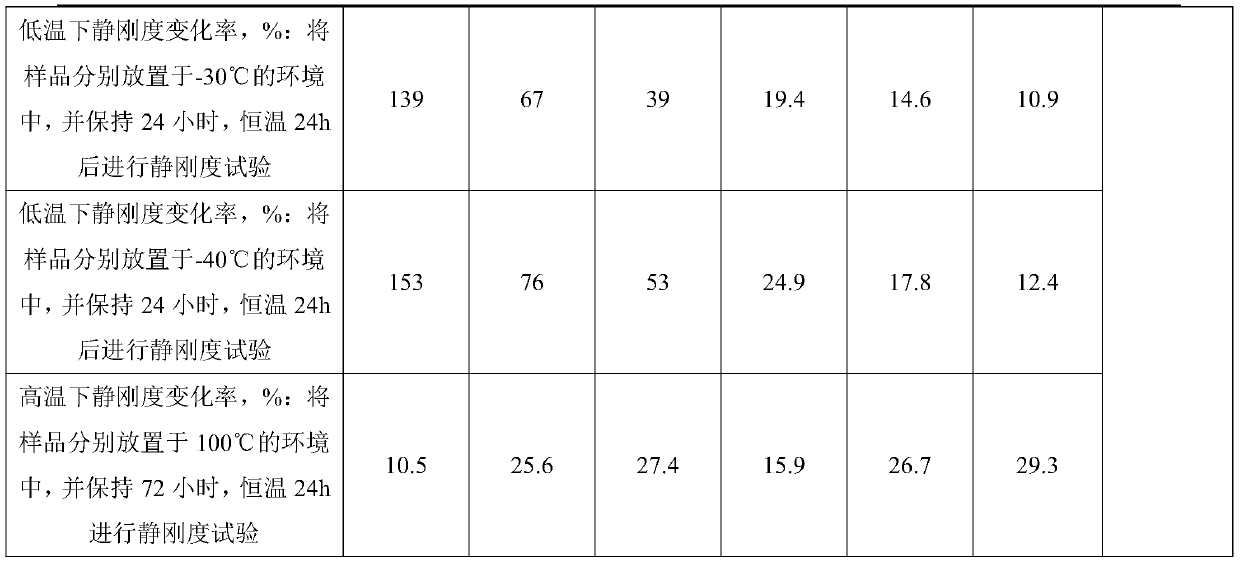

Examples

Embodiment 1

[0028] The cold-resistant EPDM composite material in the present embodiment comprises the following components in parts by weight: 70 parts of EPDM, 30 parts of EPDM, 5 parts of zinc oxide, 1 part of stearic acid, 2-thiol benzimidazole 2 parts, 50 parts of high wear-resistant carbon black, 50 parts of fast extruded carbon black, 40 parts of white carbon black, 21 parts of trioctyl phosphate, 14 parts of dioctyl sebacate, 25 parts of paraffin oil, 0.7 parts of sulfur, 1 part of N,N'-m-phenylene polymaleimide, 4 parts of dicumyl peroxide, 1.5 parts of triallyl isocyanurate, 3 parts of fatty acid ester processing aids, silane coupling 4 doses.

[0029] The preparation method of the cold-resistant EPDM composite material in the present embodiment may further comprise the steps:

[0030] (1) According to the above formula and ingredients, add EPDM and EPDM to the general rubber mixing equipment, then add metal oxide, stearic acid, anti-aging agent, softening plasticizer and other ...

Embodiment 2

[0034] The cold-resistant EPDM composite material in the present embodiment comprises the following components in parts by weight: 50 parts of EPDM, 50 parts of EPDM, 5 parts of zinc oxide, 1 part of stearic acid, 2-thiol benzimidazole 2 parts, 50 parts of high wear-resistant carbon black, 40 parts of fast extruded carbon black, 30 parts of white carbon black, 16 parts of trioctyl phosphate, 12 parts of dioctyl sebacate, 15 parts of paraffin oil, 0.5 parts of sulfur, 0.7 parts of N,N'-m-phenylene polymaleimide, 5 parts of dicumyl peroxide, 2 parts of triallyl isocyanurate, 3 parts of fatty acid ester processing aids, silane coupling 3 doses.

[0035]The preparation method of the cold-resistant EPDM composite material in this example is the same as that in Example 1.

Embodiment 3

[0037] The cold-resistant EPDM composite material in the present embodiment comprises the following components in parts by weight: 30 parts of EPDM, 70 parts of EPDM, 5 parts of zinc oxide, 1 part of stearic acid, 2-thiol benzimidazole 2 parts, 40 parts of high wear-resistant carbon black, 40 parts of fast extruded carbon black, 20 parts of white carbon black, 15 parts of trioctyl phosphate, 10 parts of dioctyl sebacate, 10 parts of paraffin oil, 0.3 parts of sulfur, 0.5 parts of N,N'-m-phenylene polymaleimide, 6 parts of dicumyl peroxide, 2.3 parts of triallyl isocyanurate, 3 parts of fatty acid ester processing aids, silane coupling 2 doses.

[0038] The preparation method of the cold-resistant EPDM composite material in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com