Multilayer composite film and application thereof

A technology of multi-layer composite film and fluorescent adhesive layer, applied in the field of fluorescent adhesive film, can solve the problems of LED packaging structure, adverse effects of light extraction efficiency and heat dissipation performance, inconsistent phosphor powder distribution, and need to improve the shelf life, etc., and achieve good fluorescent particle distribution. performance, low cost, and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095] In an embodiment of the present invention, a method for preparing the phenylsiloxane epoxy containing multiple silicon-hydrogen bonds or its isomers may include: making the cyclic compound containing multiple vinyl groups , Cyclic compounds containing multiple silicon-hydrogen bonds and compounds containing multiple silicon-hydrogen bonds and phenyl groups undergo hydrosilylation reactions in the presence of catalysts to generate phenylsiloxanes containing six silicon-hydrogen bonds Alkane epoxides or their isomers.

[0096] Preferably, the preparation method specifically includes: mixing a cyclic compound containing multiple vinyl groups, a compound containing multiple silicon-hydrogen bonds and a phenyl group, a cyclic compound containing multiple silicon-hydrogen bonds, a catalyst and an organic solvent After that, it is heated to reflux for hydrosilylation reaction to generate phenylsiloxane epoxy or its isomers containing six silicon-hydrogen bonds.

[0097] Prefe...

Embodiment approach

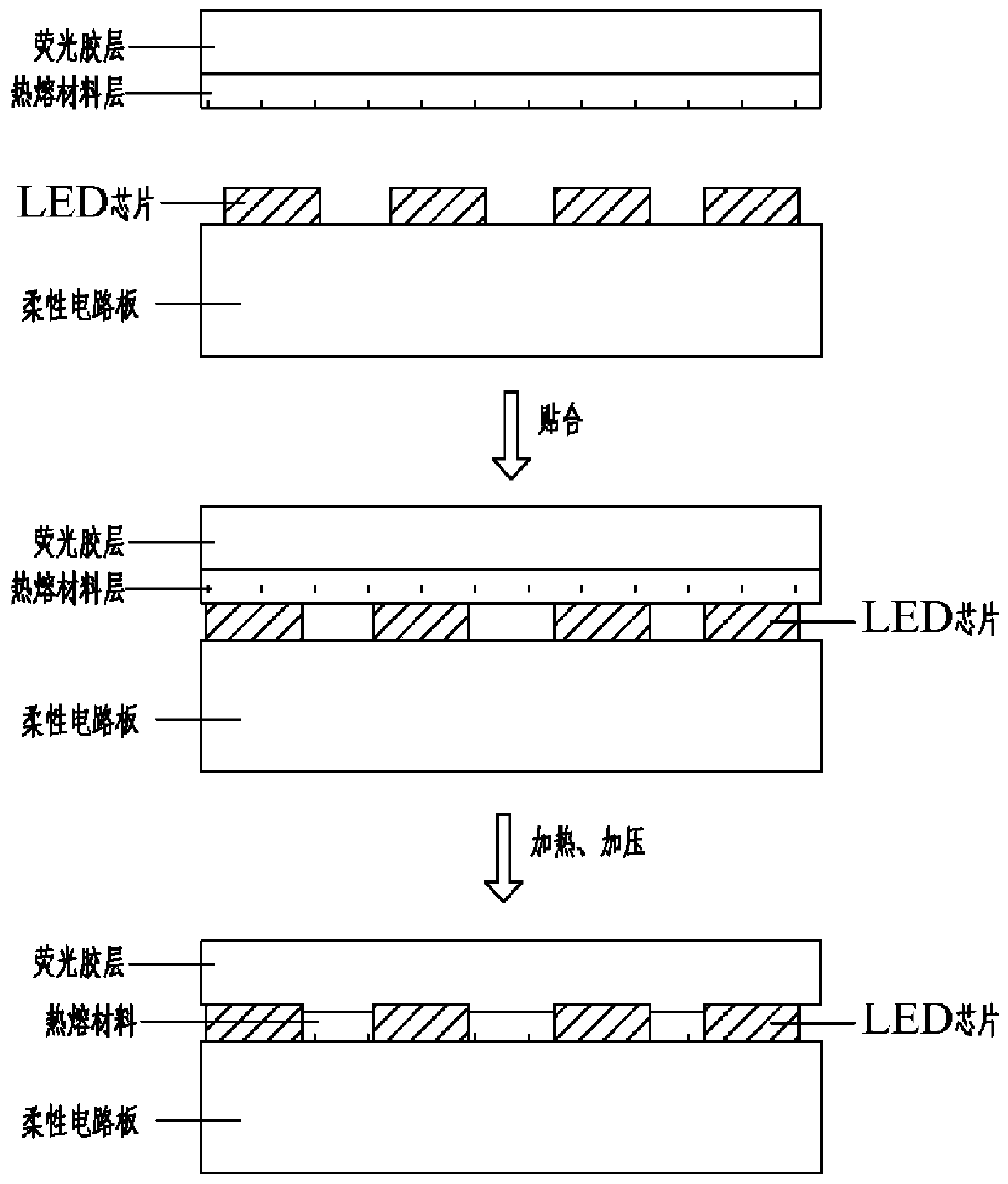

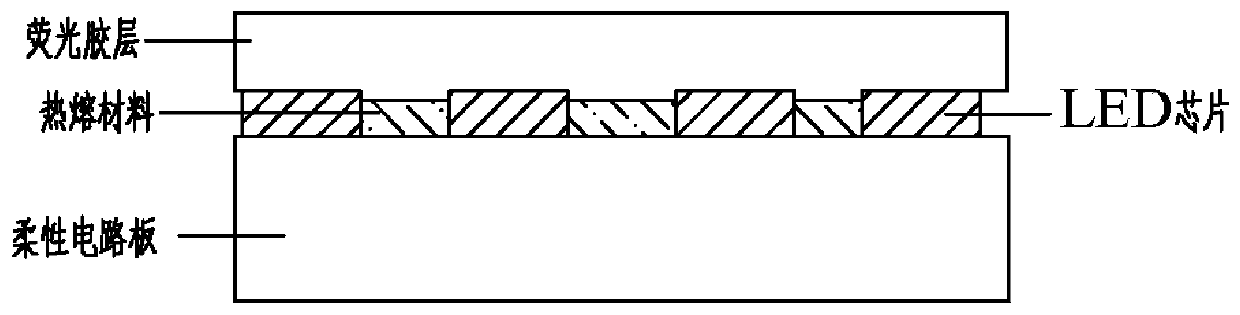

[0151] In some embodiments, the preparation method of the fluorescent adhesive layer may specifically include:

[0152] S1: film formation, the fluorescent encapsulation composition is formed into a film by means of solution film formation, casting coating, screen / stencil printing, spin coating, (vacuum) extrusion film formation, etc.;

[0153] S2: Preliminary curing to form a non-sticky and peelable pre-cured film, that is, the fluorescent adhesive layer, which has properties similar to pressure-sensitive adhesives.

[0154] In an optional embodiment, the step S2) may include: removing the organic solvent in the film under the conditions of radiation and / or heating and ventilation, so as to form the pre-cured film. The heating temperature adopted may be 20-200° C., preferably 80-120° C., and the heating time is 10-100,000 seconds, preferably 10-8,000 seconds.

[0155] Further, the fluorescent adhesive layer has a certain deformability, especially under certain pressure condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com