Preparation method and application of CsPbBr3 inorganic perovskite film

A technology of inorganic calcium and titanite, applied in the field of solar cells, can solve the problem that the inorganic perovskite film cannot be prepared in a large area, and achieve the effect of increasing the concentration of free carriers, improving the coverage, and improving the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

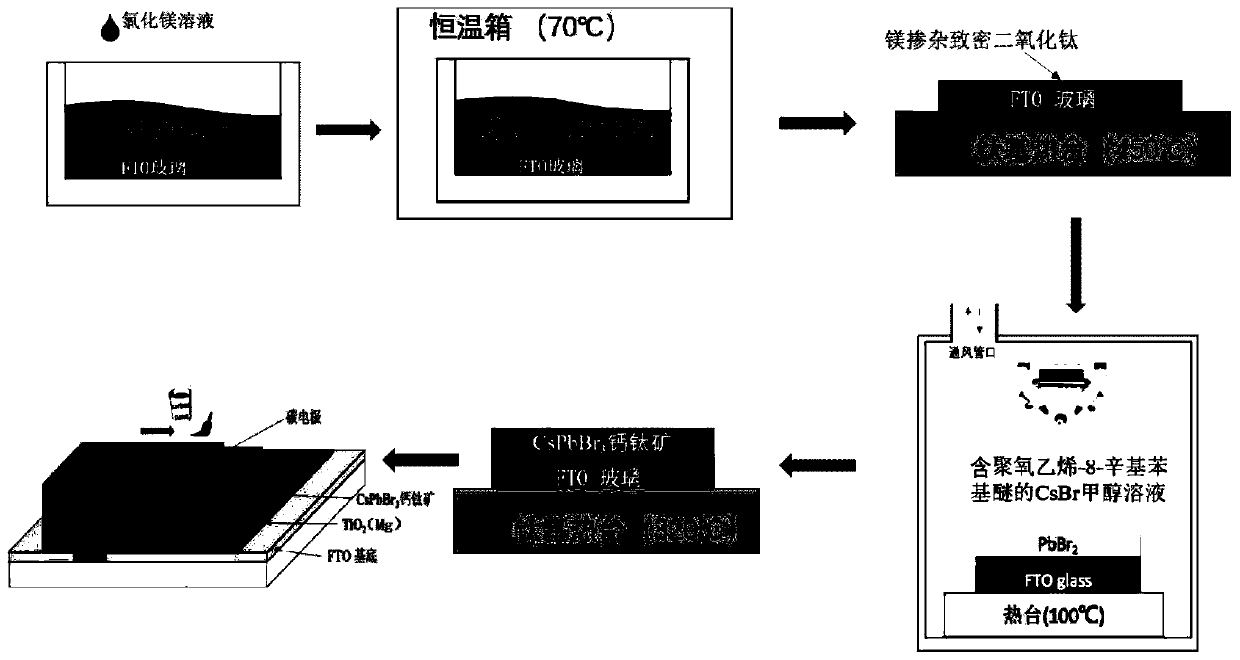

[0040] combine figure 1 Shown, the CsPbBr of this example 3 The preparation method of inorganic perovskite film specifically comprises the following steps:

[0041] 1) Add 2.5 ml of magnesium chloride aqueous solution with a concentration of 0.01 M to 100 ml of titanium dioxide precursor solution dropwise with a pipette gun to obtain solution A;

[0042] 2) Immerse the cleaned FTO conductive glass substrate in solution A, and put it in a thermostat at 70°C for 40 minutes for chemical bath deposition. After the chemical bath deposition is completed, take out the FTO conductive glass substrate and use Rinse with water, then blow dry with nitrogen, this process is repeated twice, and then heat treatment is carried out on a titanium-based hot stage at 450°C for 30 minutes to obtain a magnesium-doped titanium dioxide dense layer;

[0043]3) Place the FTO conductive glass substrate deposited with a dense layer of magnesium-doped titanium dioxide into a UV cleaning machine for clea...

Embodiment 2

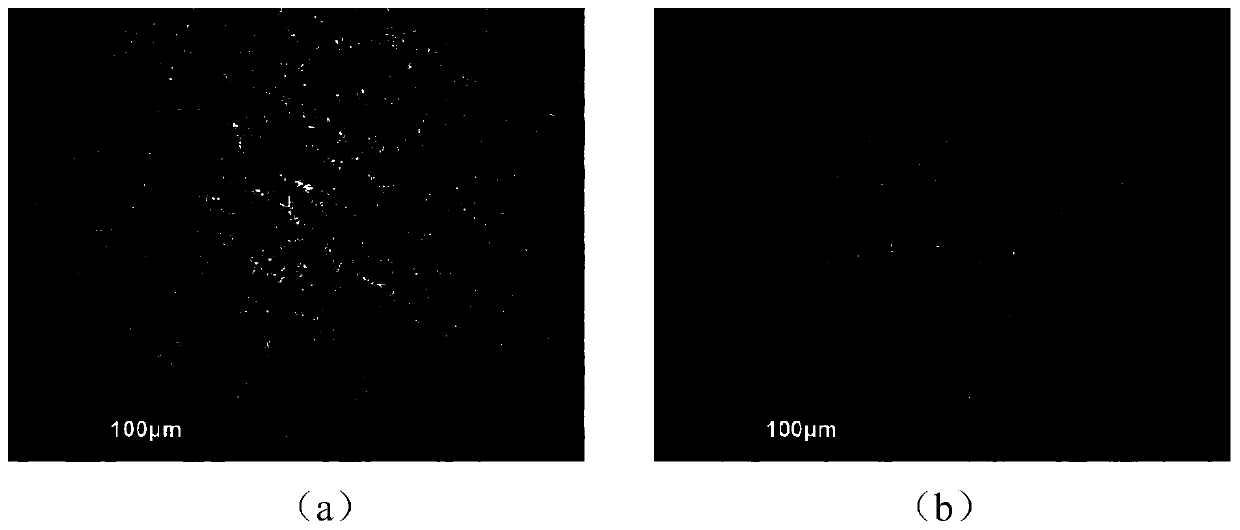

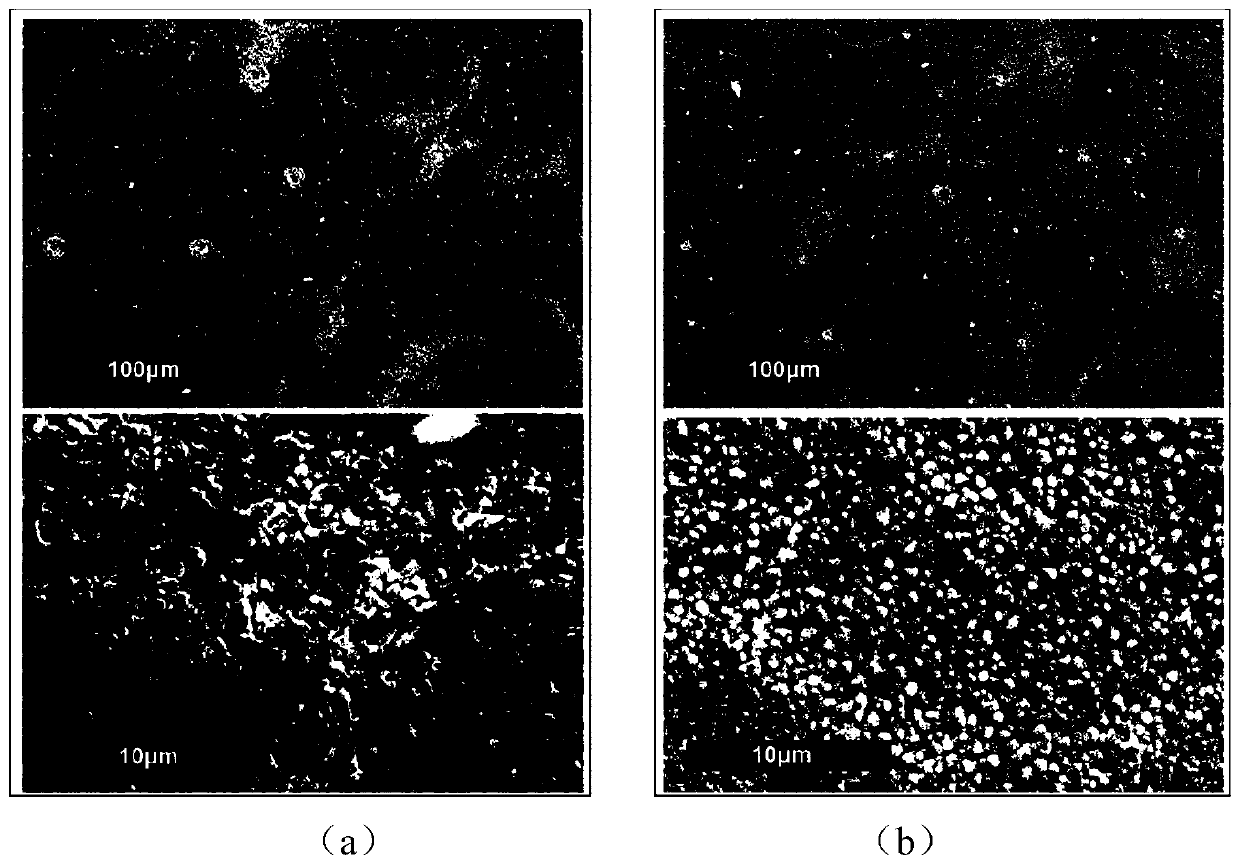

[0052] combine figure 1 As shown, the difference between the present embodiment and embodiment 1 is: the dimethylformamide solution of lead bromide in the present embodiment step 3) is introduced with 0.4mg of polyoxyethylene-8-octyl as surfactant before spraying Base phenyl ether, a methanol solution of cesium bromide was introduced with 4 mg of polyoxyethylene-8-octyl phenyl ether as a surfactant before spraying. Wherein, the concentration of polyoxyethylene-8-octylphenyl ether in the dimethylformamide solution of lead bromide and the methanol solution of cesium bromide is both 0.0003M.

[0053] It should be noted that the surfactant in the present invention is not limited to the above-mentioned polyoxyethylene-8-octylphenyl ether, and it can also be other substances with dispersing properties, such as sodium lauryl sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com