Method for preparing platinum-based catalyst by using atomic layer deposition (ALD) technology, and applications of platinum-based catalyst in propane dehydrogenation reaction

An atomic layer deposition and catalyst technology, applied in the direction of catalysts, carbon compound catalysts, chemical instruments and methods, etc., can solve the problems of limited industrial application process, insufficient anti-coking ability of catalysts, and reduced catalyst activity, and achieve excellent anti-carbon deposition. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] γ-Al 2 o 3 Calcined at 600°C for 4h in an air atmosphere to obtain an alumina carrier. Then weigh 0.02gSnCl 4 ·5H 2 O was dissolved in 3ml of ethanol, and this tin chloride solution was added dropwise onto 1g of alumina carrier, keeping the Sn content at 0.68wt%. Then seal it with a plastic wrap, let it stand at room temperature for 2 hours, put it into a vacuum oven at 30°C, and dry it overnight. The obtained sample was calcined at 590° C. for 2 hours in an air atmosphere, and then ground into powder to prepare a modified alumina carrier.

Embodiment 2

[0024] The tin-modified alumina prepared in Example 1 was used as a carrier to support platinum nanoparticles by ALD method. The specific method is as follows: dimethylcyclopentadiene hexaplatinum is used as a platinum precursor, ozone is used as a counter reactant, the evaporation temperature of the platinum precursor is 50°C, and the reaction temperature is 150°C. The process of preparing metal platinum nanoparticles: platinum precursor pulse time 150 seconds nitrogen purge 180 seconds, ozone pulse 50 seconds, nitrogen purge 180 seconds, grow a cycle of platinum nanoparticles, get catalyst 0.5% Pt-Sn / Al 2 o 3 , denoted as 0.5%Pt-Sn / Al 2 o 3 -ALD.

Embodiment 3

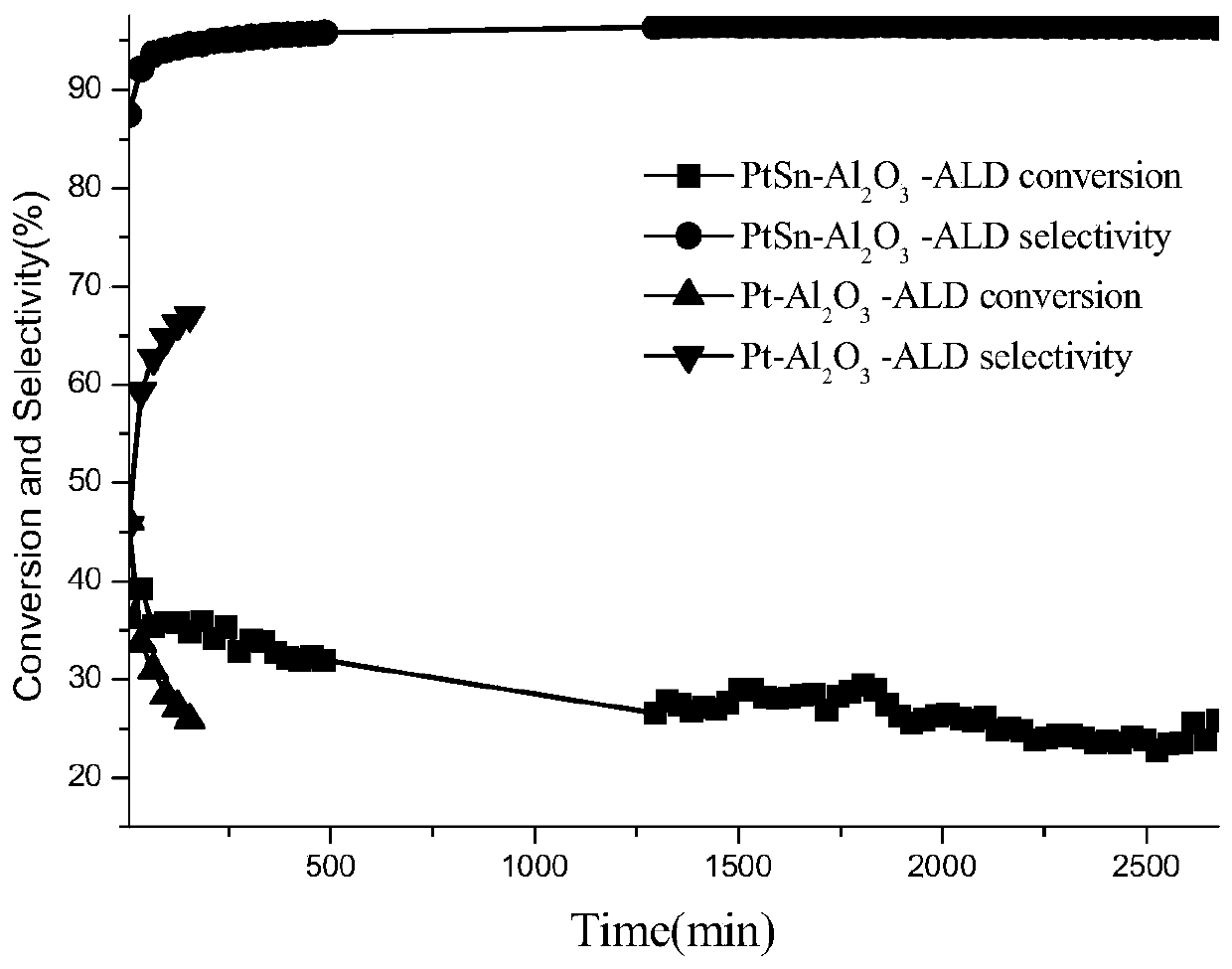

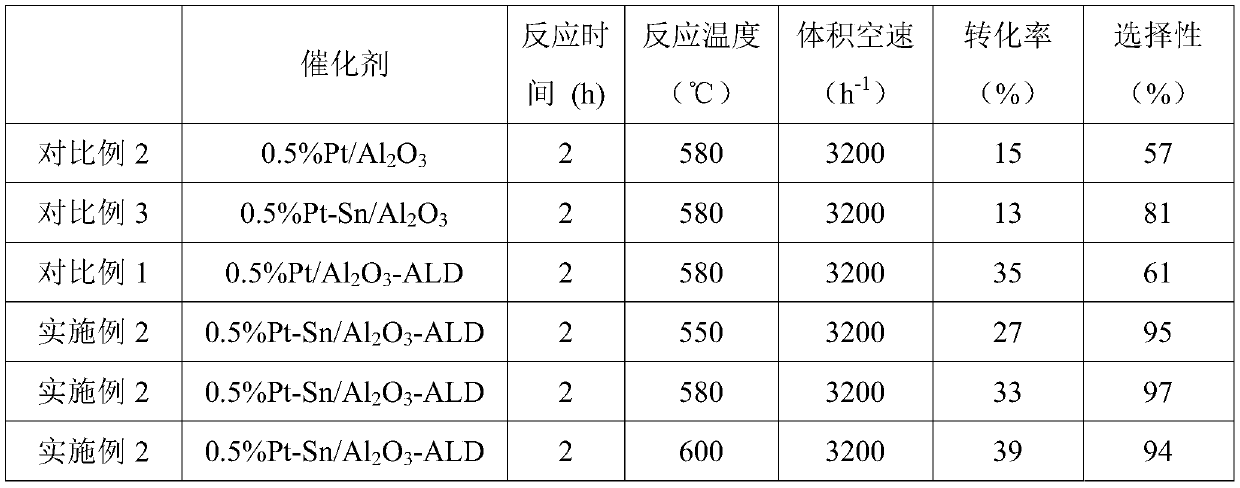

[0032] Above-mentioned catalyzer (embodiment 2, comparative example 1, comparative example 2, comparative example 3) is evaluated in fixed-bed reactor, and catalyst loading is 10ml, and catalyst is first reduced 2 hours under 550 ℃ of hydrogen atmospheres before reaction, Then pass reaction gas (propane:hydrogen = 1:1) at 500-600°C for reaction, the reaction pressure is normal pressure reaction, and the gas space velocity is 3200h -1 . Concrete reaction result is as shown in table 1 below:

[0033] Table 1

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com