Modified extracellular matrix hydrogel and its preparation method and application, tissue engineering material

A tissue engineering and extramatrix technology, used in pharmaceutical formulations, prostheses, drug delivery, etc., can solve problems such as easy degradation, inability to form gels, poor treatment effects, etc., to achieve wide sources, maintain mechanical strength, good Effects of Cell Affinity Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

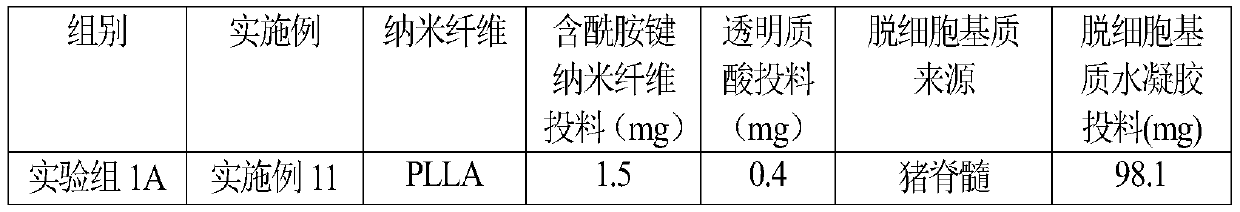

Examples

Embodiment 1

[0048] The preparation of the decellularized matrix hydrogel derived from spinal cord comprises the following steps:

[0049] The fresh spinal cord of pigs obtained from the slaughterhouse, under low temperature conditions, peel off the outer membrane of the spinal cord and cut it into 1.5-2cm length, put it into the pre-cooled phosphate buffer saline (PBS) solution, PBS and put into The volume ratio of the spinal cord is about 4:1; then, under the condition of ice bath, put the screw bottle containing the spinal cord on a decolorization shaker, and shake it at a speed of 160rpm for at least 4 hours; filter the excess liquid with gauze, Then put the remaining spinal cord structure into the screw bottle, add double distilled water to 500mL, put it into the shaker again, and repeat this process until only the transparent cytoskeleton remains in the spinal cord. This process needs to go through 7 to 8 cycles. Fully remove the gray matter, white matter and cytoplasmic components i...

Embodiment 2

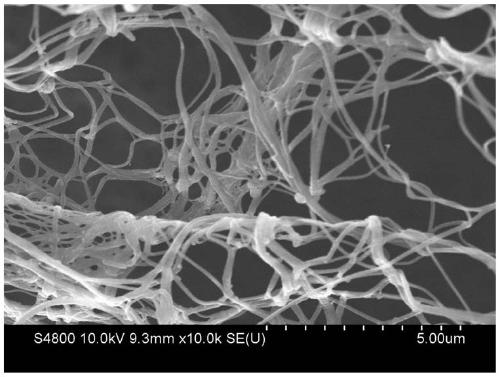

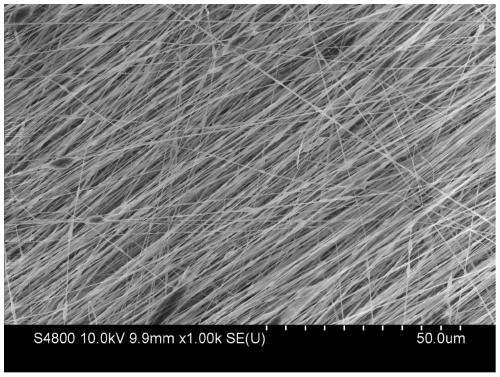

[0051] The preparation of PLLA electrospinning nanofiber membrane containing amide bond comprises the following steps:

[0052] Weigh a certain amount of poly-L-lactic acid (PLLA) powder, add 2 mL of hexafluoroisopropanol (HFIP) and stir for 12 h to fully dissolve PLLA and obtain a PLLA solution with a mass concentration of 7.5%. Inject the solution prepared above into a 5mL glass syringe, install a 20g stainless steel needle and install it on the electrospinning device, take a flat tinfoil paper and fix it on the receiving end, adjust the receiving distance and set a suitable Under high voltage and flow rate, the PLLA solution forms oriented fiber filaments under high pressure and is received on the receiving plate of tin foil paper, and the ambient temperature is controlled at 30 °C. The process parameters for preparing PLLA spinning fiber bundles are as follows: the spinning voltage is 15kV, the distance between the spinning needle and the receiver is 30cm, and the spinning...

Embodiment 3

[0054] The preparation of PLA electrospinning nanofiber membrane containing amide bond comprises the following steps:

[0055] Weigh an appropriate amount of polylactic acid (PLA) powder, add 3mL N,N-dimethylformamide (DMF) and let it stand for 8 hours to fully dissolve PLA and obtain a PLA solution with a mass concentration of 8.0%. Inject the solution prepared above into a 5mL glass syringe, install a 20g stainless steel needle and install it on the electrospinning device, take a flat tinfoil paper and fix it on the receiving end, adjust the receiving distance and set a suitable Under high voltage and flow rate, the PLLA solution forms oriented fiber filaments under high pressure and is received on the receiving plate of tin foil paper, and the ambient temperature is controlled at 30 °C. The process parameters for preparing PLA spinning fiber bundles are as follows: the spinning voltage is 15kV, the distance between the spinning needle and the receiver is 30cm, and the spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com