Nanofiber, preparation method thereof and embedded capacitive material

A nanofiber and nanoconductive technology, which is applied in the field of embedded capacitor materials, can solve the problems such as the inability to increase the dielectric constant of materials, and achieve the effects of loose process conditions, increased dielectric constant, and increased charge polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

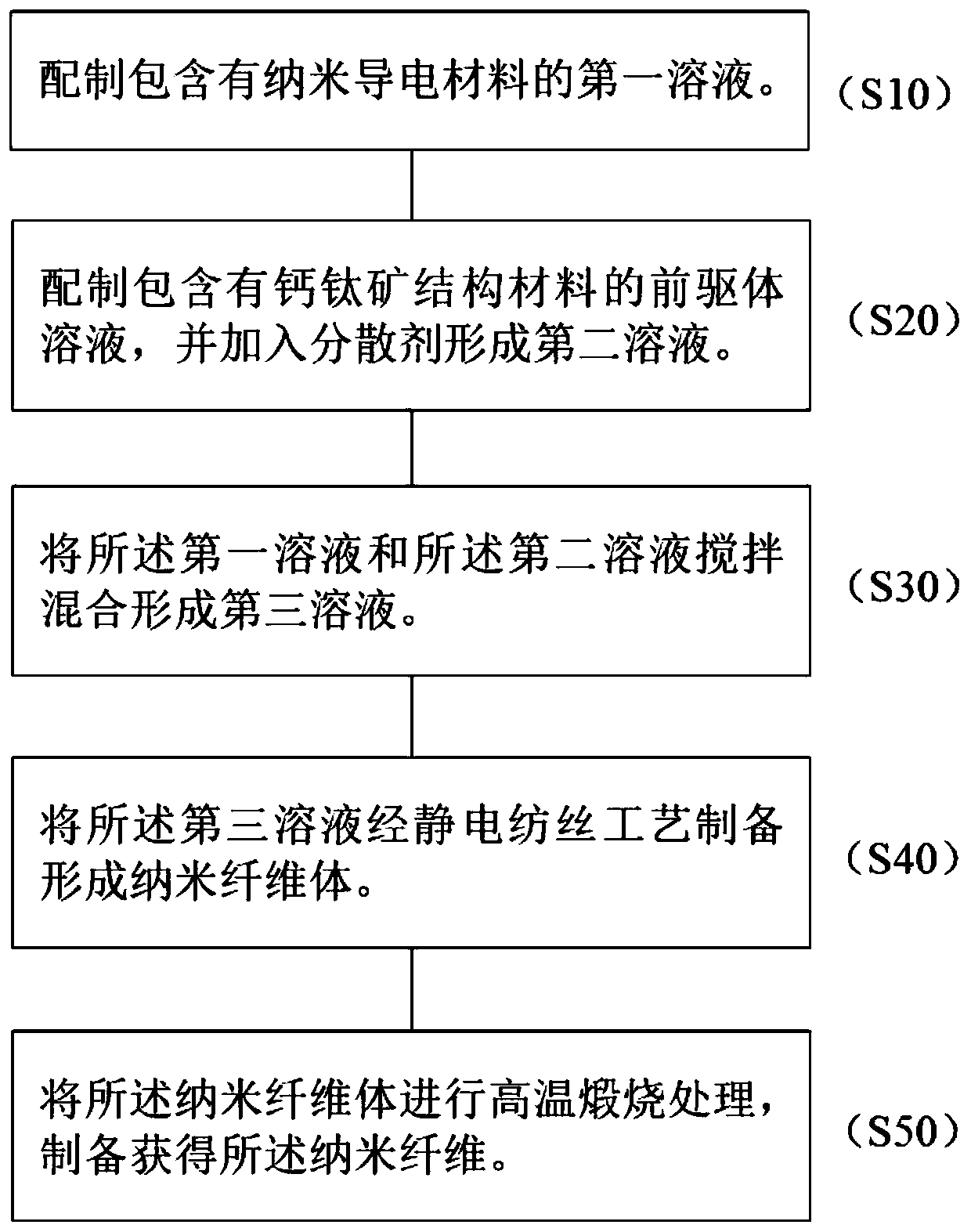

[0035] Specifically, see image 3 , the preparation method of the nanofiber comprises the steps:

[0036] S10. Prepare a first solution containing nano conductive material.

[0037] Specifically, the nano conductive material is prepared first; then the nano conductive material is added into an organic solvent to stir and disperse to obtain the first solution. Wherein, the nano-conductive material can be selected from metal nano-conductive particles, carbon nanotubes and / or graphene; the organic solvent can be selected from acetic acid, ethylene glycol methyl ether, isopropanol and the like.

[0038] In the specific scheme, the preparation of metal nano conductive particles: the metal nano conductive particles are prepared by liquid phase reduction method, wherein ascorbic acid, sodium borohydride, hydrazine hydrate, ethylene glycol, etc. are selected as reducing agents, and metal salts such as chloroauric acid are selected. , Ferrous chloride, ferrous sulfate heptahydrate, c...

Embodiment 1

[0054] Example 1: Ag@BST / PVDF composite material

[0055] (1), the AgNO 3 Dissolve PVP in ethylene glycol, ultrasonically for 10-60 minutes, after it is completely dissolved, add it to a three-necked flask, heat up to 130°C, heat in an oil bath for 10-40 minutes, and pour the suspension on it after it has completely reacted Go, wash the remaining nano-Ag particles twice with ethanol, and then disperse them in acetic acid, called the first solution, for use.

[0056] (2), dissolving strontium acetate and barium acetate in acetic acid, stirring magnetically for 10 to 30 minutes, called solution B, for use; pouring tetrabutyl titanate and acetylacetone into a beaker, stirring magnetically for 10 to 30 minutes, and then Add the above solution B, and stir magnetically for 20-40 minutes to obtain the second solution.

[0057] (3) Add the second solution to the first solution, stir magnetically for 20-40 minutes, then add PVP (polyvinylpyrrolidone), stir magnetically for 12-24 hour...

Embodiment 2

[0062] Embodiment 2: Cu@BST / epoxy resin composite material

[0063] (1), the CuCl 2 Dissolve PVP in ethylene glycol, ultrasonically for 10-60 minutes, after it is completely dissolved, add it to a three-necked flask, heat up to 140°C, heat in an oil bath for 30-120 minutes, and pour the suspension on it after it has completely reacted Next, the remaining nano-Cu particles were washed twice with ethanol, and then dispersed in acetic acid, called the first solution, for use.

[0064] (2) Dissolve strontium acetate and barium acetate in acetic acid, stir magnetically for 10-30min, call it B solution, and set aside; pour tetrabutyl titanate and acetylacetone into a beaker, stir magnetically for 10-30min, Then add the above B solution, and magnetically stir for 20min-40min to obtain the second solution.

[0065] (3) Add the second solution to the first solution, stir magnetically for 20-40 minutes, then add PVP (polyvinylpyrrolidone), stir magnetically for 12-24 hours, and call i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com