A method for detecting n-dimethylnitrosamine in meat food

A technology of dimethylnitrosamine and meat food, which is applied in the field of food testing, can solve the problems of unfavorable batch processing, cumbersome operation, large sample consumption, etc., improve the detection accuracy and recovery rate, simplify the pretreatment steps, The effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

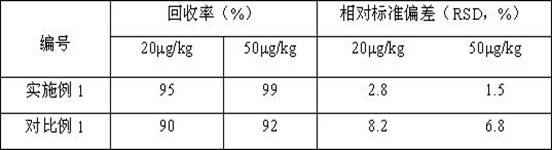

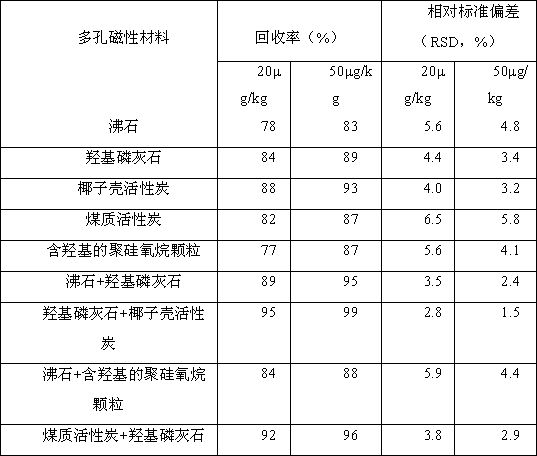

Embodiment 1

[0042] In this embodiment, pork products are selected for measurement, and the processing method is as follows: After selecting 100 g of pork and pulverizing, add 250 g of deionized water, 40 g of barium hydroxide, 20 g of sodium chloride, and 60 g of porous magnetic coconut shell activated carbon with a particle diameter of 150 nm and granular 70g of porous magnetic hydroxyapatite with a diameter of 300nm, stirred evenly, sealed and subjected to ultrasonic treatment for 20min, applied a magnetic field to adsorb the porous magnetic adsorption material to separate it, and obtained the mixed solution B;

[0043] Then, take 200g of dichloromethane to dilute and separate the mixed solution B, ultrasonically extract for 12min, then let stand for 5min to obtain the extract, mix the extract with the porous magnetic adsorption material, continue to stir for 10min, and then apply a magnetic field to adsorb the porous magnetic adsorption material It is separated to obtain mixed solution ...

Embodiment 2

[0054] In this embodiment, chicken products are selected for measurement, and the processing method is as follows: After selecting 100 g of chicken and pulverizing, add 200 g of deionized water, 30 g of barium hydroxide, 40 g of sodium chloride, and 60 g of porous magnetic coconut shell activated carbon with a particle size of 200 nm and granular 60g of porous magnetic hydroxyapatite with a diameter of 300nm, stirred evenly, sealed and subjected to ultrasonic treatment for 15min, applied a magnetic field to adsorb the porous magnetic adsorption material to separate it, and obtained the mixed solution B;

[0055] Then, take 250g of dichloromethane to dilute and separate the mixed solution B, ultrasonically extract for 10min, then let stand for 5min to obtain the extract, mix the extract with the porous magnetic adsorption material, continue to stir for 10min, and then apply a magnetic field to adsorb the porous magnetic adsorption material It is separated to obtain mixed solutio...

Embodiment 3

[0058] In this embodiment, chicken products are selected for measurement, and the processing method is as follows: after 100 g of chicken is selected and pulverized, 240 g of deionized water, 35 g of barium hydroxide, 26 g of sodium chloride, and 50 g of porous magnetic coconut shell activated carbon with a particle diameter of 100 nm and granules are added successively. Diameter is 60g of porous magnetic zeolite of 300nm, after stirring evenly, seal and carry out ultrasonic treatment 15min, apply magnetic field to adsorb porous magnetic adsorption material to separate it, obtain mixed solution B;

[0059] Then, take 250g of dichloromethane to dilute and separate the mixed solution B, ultrasonically extract it for 10 minutes, then let it stand for 5 minutes to obtain the extract, mix the extract with the porous magnetic adsorption material, continue stirring for 15 minutes, and then apply a magnetic field to adsorb the porous magnetic adsorption material It is separated to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com