Fully-biodegradable slow-release solid carbon source capable of being directly released and preparation method and application of fully-biodegradable slow-release solid carbon source

A solid carbon source, biodegradation technology, applied in chemical instruments and methods, biological water/sewage treatment, water treatment parameter control, etc. The effect of easy release of carbon source and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

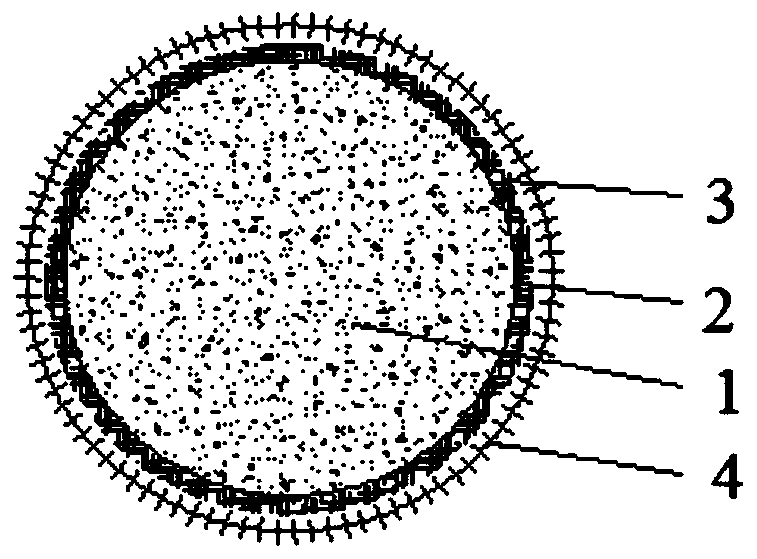

[0042] Embodiment 1 provides a kind of such as figure 1 The slow-release solid carbon source shown. Its preparation method is as follows:

[0043] Weigh 10kg BioC-1M carbon source, 40kg sawdust crude fiber, 10kg polylactic acid (PLA) nano spinning fiber, 10g potassium sulfate, 1g vitamin B1 and 10kg binder, after uniform mixing, make carbon source matrix 1; Be that 5 centimeters in diameter, thickness be 0.03 centimeter cotton net 2 (aperture diameter is in Φ 12) wrapping all carbon source substrates 1, and fasten; Then use the polylactic acid (PLA) non-woven fabric that is 5.5 centimeters in diameter (as Fig. The biodegradable non-woven fabric 1) as shown, the coating thickness is 0.2 cm, which can obtain the slow-release solid carbon source body.

[0044] In practice, during application, the slow-release solid carbon source body is covered with a filler shell 4 (which can be plastic, metal or ceramic Pall rings), and then put into use.

Embodiment 2

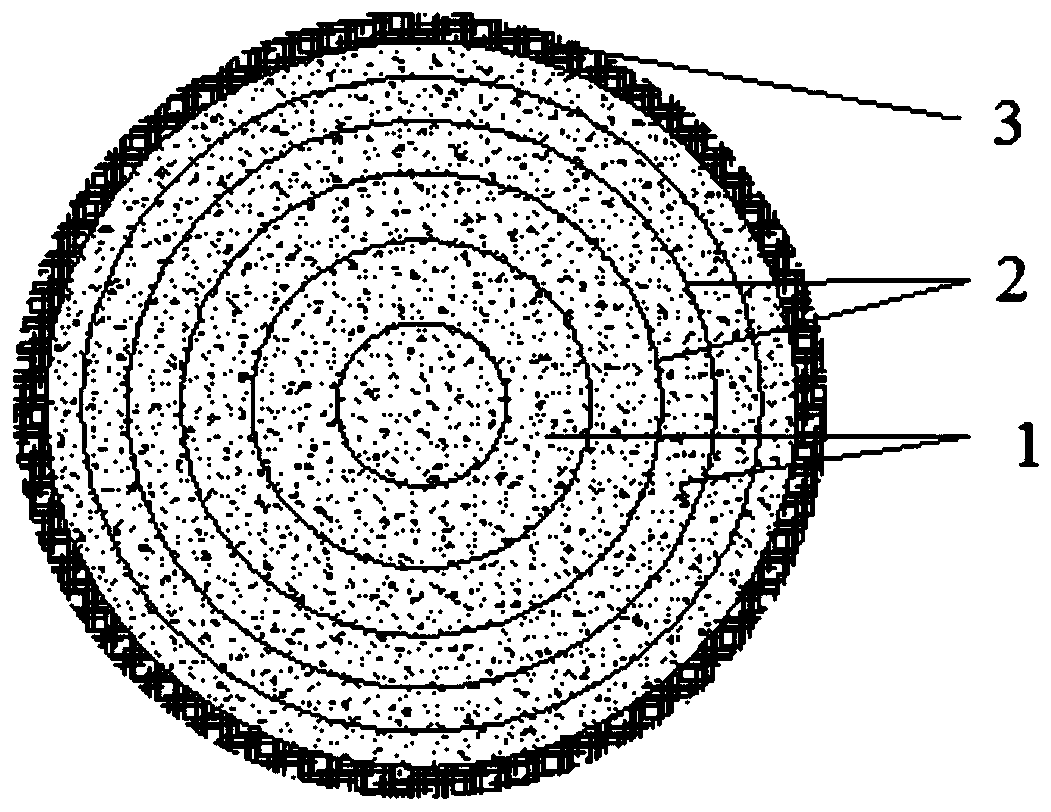

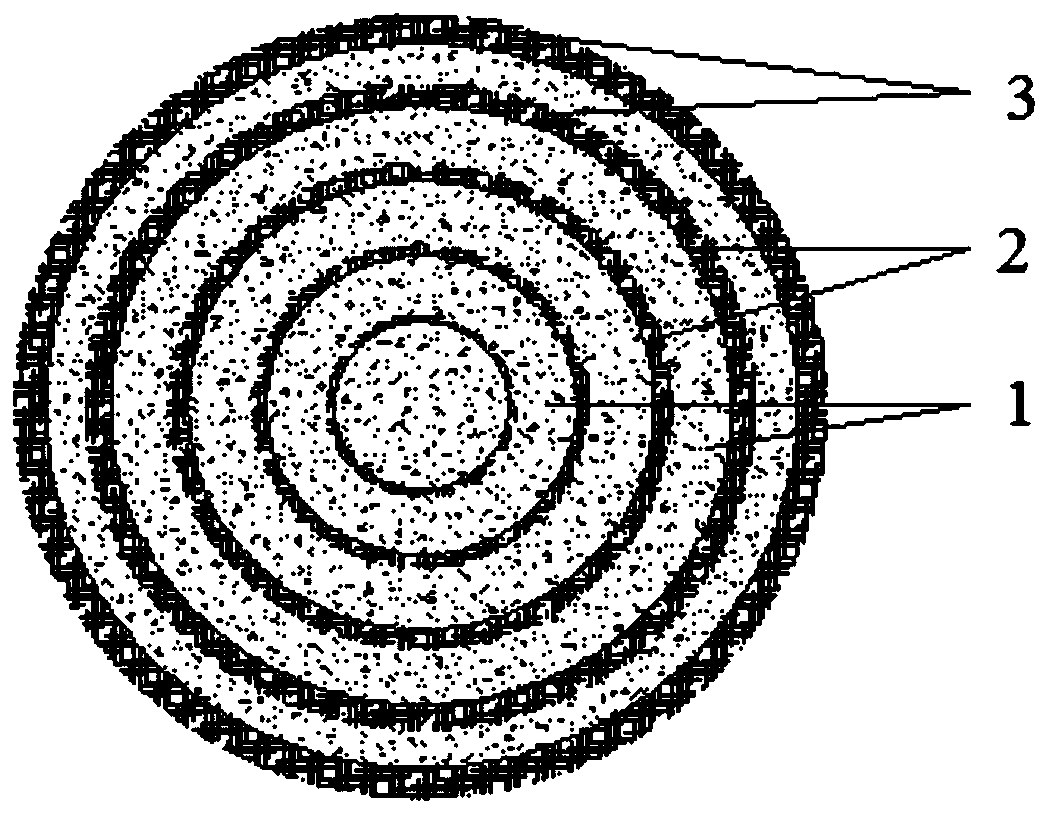

[0046] Embodiment 2 provides a kind of such as figure 2 The slow-release solid carbon source shown. Its preparation method is as follows:

[0047] a) Prepare the following raw materials:

[0048] Take by weighing 15kg sodium acetate, 55kg shredded paper and 20kg polycaprolactone (PCL) nano spinning fiber, 100g potassium sulfate, 5g vitamin B1 and 20kg binding agent, after uniform mixing, make carbon source matrix 1, and make The resulting carbon source matrix 1 is divided into 6 parts, and the mass is increased by 10% in turn, which are respectively recorded as 1#, 2#, 3#, 4#, 5#, and 6# substrates;

[0049] Take 6 pieces of cotton net 2 (the thickness of the cotton net is 0.03 cm, and the aperture is Φ12) with diameters of 1 cm, 2 cm, 3 cm, 3.8 cm, 4.5 cm, and 5 cm, and record them as 1#, 2#, and 3 #, 4#, 5#, 6# cotton mesh;

[0050] Another piece of polylactic acid (PLA) non-woven fabric with a diameter of 5.5 cm and a thickness of 0.2 cm (biodegradable non-woven fabric...

Embodiment 3

[0054] Embodiment 3 provides a kind of such as figure 2 The slow-release solid carbon source shown. Its preparation method can refer to Example 2, the difference is: when preparing carbon source matrix 1, weigh 30kg glucose, 40kg paper scraps and 30kg polybutylene succinate (PBS) nano spinning fiber, 200g magnesium sulfate, 6.5 g of vitamin B12 and 25kg of adhesive are uniformly mixed to make carbon source matrix 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com