Reinforced cement retarder and preparation method thereof

A cement retarder and reinforced technology, applied in the field of reinforced cement retarder and its preparation, can solve the problems of reduced cement strength, unguaranteed engineering quality, etc., so as to reduce production costs, overcome limitations and deficiencies, Good retardation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

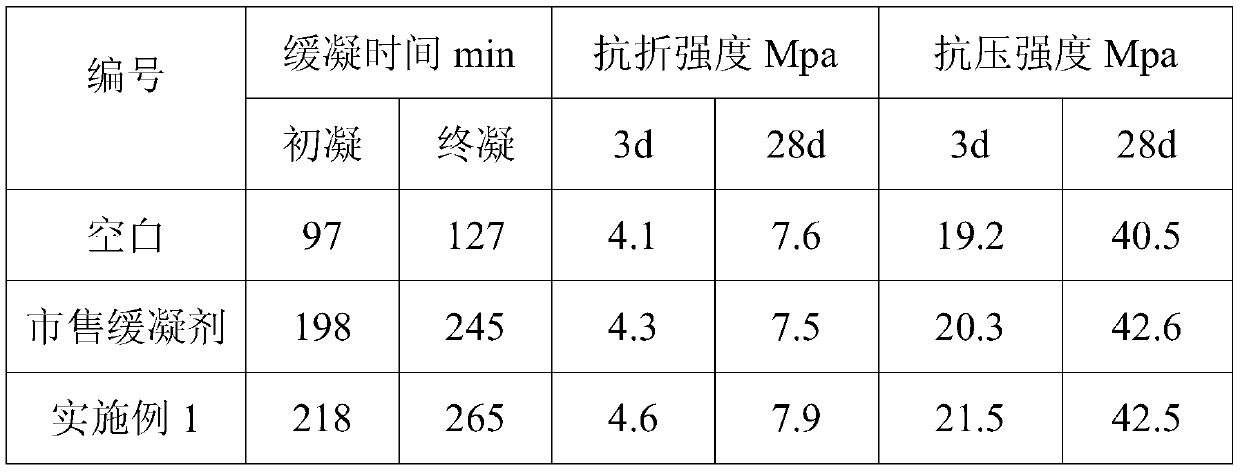

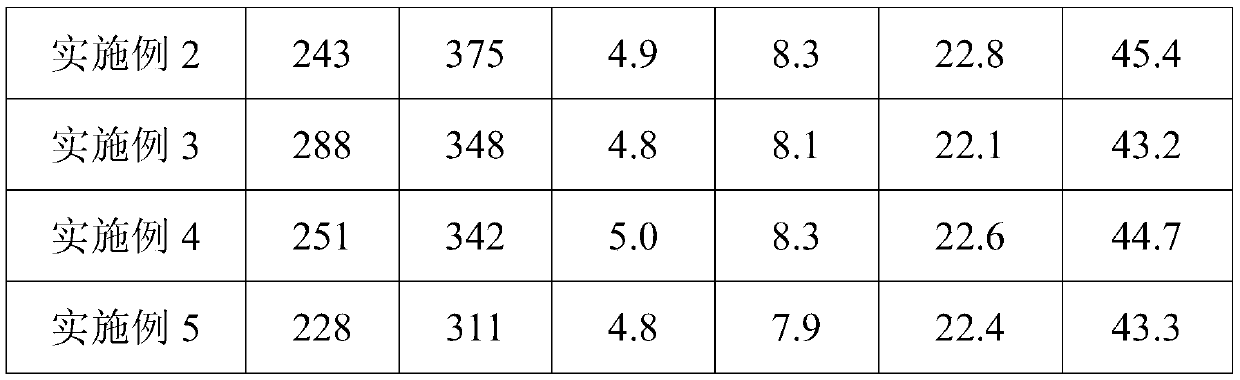

Embodiment 1

[0021] A kind of enhanced cement retarder, its raw material composition is: Tetrahydroxyethylethylenediamine 3%, dispersant 0.1%, sodium tripolyphosphate 1%, molasses 30%, sodium gluconate 5%, sodium hexametaphosphate 3%, tetrahydroxypropyl ethylenediamine 1%, the balance is water, and the total amount is 100%; said percentages are all mass percentages.

[0022] The percentages are all mass percentages. According to the formula ratio, dissolve tetrahydroxyethylethylenediamine, dispersant, sodium tripolyphosphate, molasses, sodium gluconate, sodium hexametaphosphate, and tetrahydroxypropylethylenediamine in water , and mix evenly to obtain product 1.

Embodiment 2

[0024] A kind of enhanced cement retarder, its raw material composition is: Tetrahydroxyethylethylenediamine 6%, dispersant 0.3%, sodium tripolyphosphate 3%, molasses 40%, sodium gluconate 10%, sodium hexametaphosphate 5%, tetrahydroxypropyl ethylenediamine 3%, the balance is water, and the total amount is 100%; said percentages are all mass percentages.

[0025] The percentages are all mass percentages. According to the formula ratio, dissolve tetrahydroxyethylethylenediamine, dispersant, sodium tripolyphosphate, molasses, sodium gluconate, sodium hexametaphosphate, and tetrahydroxypropylethylenediamine in water , and mix evenly to obtain product 2.

Embodiment 3

[0027] A kind of enhanced cement retarder, its raw material is composed of: Tetrahydroxyethylethylenediamine 4%, dispersant 0.2%, sodium tripolyphosphate 2%, molasses 35%, sodium gluconate 8%, sodium hexametaphosphate 4%, tetrahydroxypropyl ethylenediamine 2%, the balance is water, and the total amount is 100%; said percentages are all mass percentages.

[0028] The percentages are all mass percentages. According to the formula ratio, dissolve tetrahydroxyethylethylenediamine, dispersant, sodium tripolyphosphate, molasses, sodium gluconate, sodium hexametaphosphate, and tetrahydroxypropylethylenediamine in water , and mix evenly to obtain product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com