A kind of water-soluble lignin chelating agent and its preparation method and application

A technology of water-soluble lignin and chelating agent, applied in the field of water-soluble lignin chelating agent and preparation thereof, lignin chelating agent and preparation thereof, can solve the problems of poor dispersion effect and low chelating efficiency, and achieve good chelation The effect of high performance, chelation efficiency and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

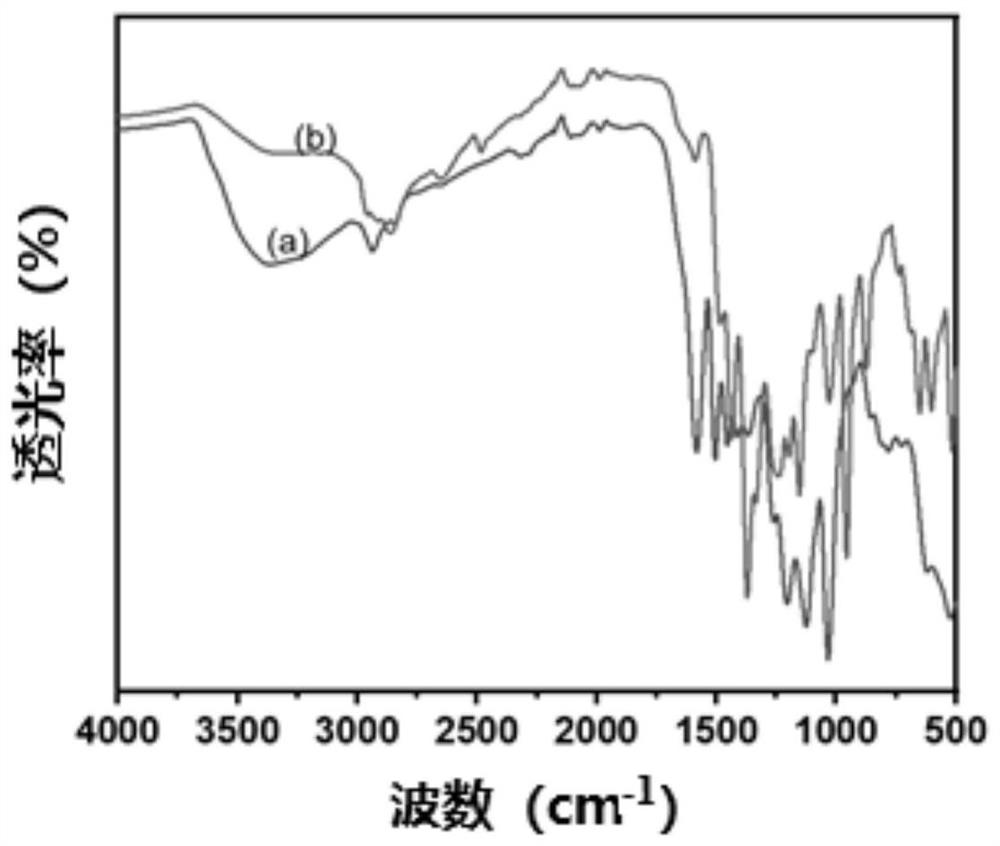

Method used

Image

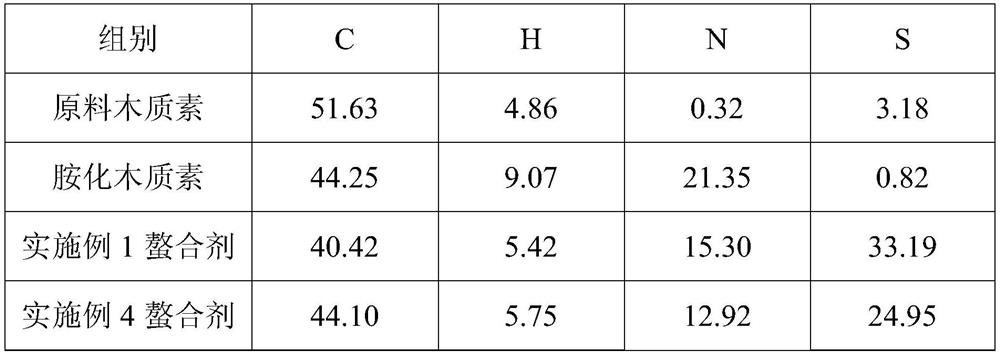

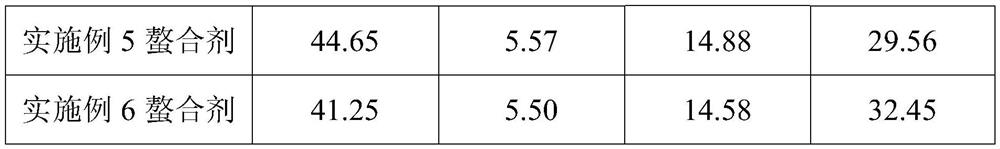

Examples

Embodiment 1

[0049] This embodiment provides a water-soluble lignin chelating agent, the water-soluble lignin chelating agent includes the following preparation raw materials in parts by weight: 10 parts of alkaline lignin, 15 parts of formaldehyde, 35 parts of amines, 50 parts of carbon disulfide share. Its preparation method is:

[0050] (1) Weigh 1.0000g of lignin into a 500mL three-neck flask, add 250mL of pure water to mix, stir until completely dissolved, and obtain an alkaline lignin aqueous solution;

[0051] (2) Adjust the pH value of the alkaline lignin aqueous solution obtained in step (1) to 11 with 1mol / L sodium hydroxide, add anhydrous ethylenediamine and formaldehyde solution dropwise, and carry out amination reaction at 90°C 5h (this process uses a condensing reflux device for cooling reflux);

[0052] (3) Adjust the pH value of the final reaction system obtained in step (2) to 10, then slowly add carbon disulfide to it for mixing, and stir at 25° C. for esterification fo...

Embodiment 2

[0055] This embodiment provides a water-soluble lignin chelating agent, the water-soluble lignin chelating agent includes the following preparation raw materials in parts by weight: 10 parts of alkaline lignin, 11 parts of formaldehyde, 30 parts of amines, 40 parts of carbon disulfide share. Its preparation method is:

[0056] (1) Weigh 1.0000g of lignin into a 500mL three-neck flask, add 250mL of pure water to mix, stir until completely dissolved, and obtain an alkaline lignin aqueous solution;

[0057] (2) Adjust the pH value of the alkaline lignin aqueous solution obtained in step (1) to 13 with 1mol / L calcium hydroxide, add diethylenetriamine solution and formaldehyde solution dropwise, and carry out amination reaction at 80°C 6h (this process uses a condensing reflux device for cooling reflux);

[0058] (3) Adjust the pH value of the final reaction system obtained in step (2) to 9.5, then slowly add carbon disulfide to it for mixing, and stir at 20°C for esterification ...

Embodiment 3

[0061] This embodiment provides a water-soluble lignin chelating agent, the water-soluble lignin chelating agent includes the following preparation raw materials in parts by weight: 10 parts of alkaline lignin, 20 parts of formaldehyde, 40 parts of amines, 60 parts of carbon disulfide share. Its preparation method is:

[0062] (1) Weigh 1.0000g of lignin into a 500mL three-neck flask, add 250mL of pure water to mix, stir until completely dissolved, and obtain an alkaline lignin aqueous solution;

[0063] (2) Use 1mol / L sodium hydroxide to adjust the pH value of the alkaline lignin aqueous solution obtained in step (1) to 12, add anhydrous ethylenediamine and formaldehyde solution dropwise, and carry out amination reaction at 90°C 4h (this process uses a condensing reflux device for cooling reflux);

[0064] (3) Adjust the pH value of the final reaction system obtained in step (2) to 10.5, then slowly add carbon disulfide to it for mixing, and stir at 30° C. for esterificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com