Preparation method of a molybdenum-doped cobalt-iron oxide nanosheet bifunctional electrocatalyst

A technology of cobalt iron oxide and electrocatalyst, which is applied in the field of two-dimensional electrocatalyst preparation, can solve the problems of restricting large-scale application and high cost, and achieve excellent OER activity and stability, easy operation, and excellent long-term cycle durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

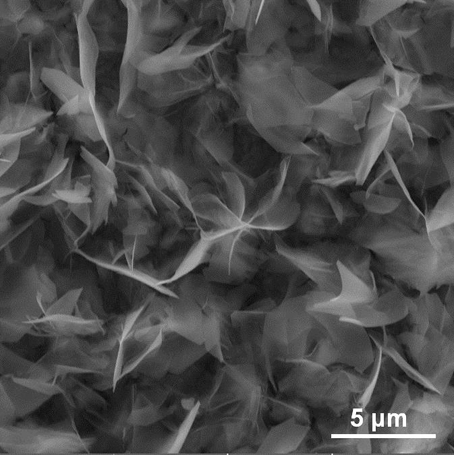

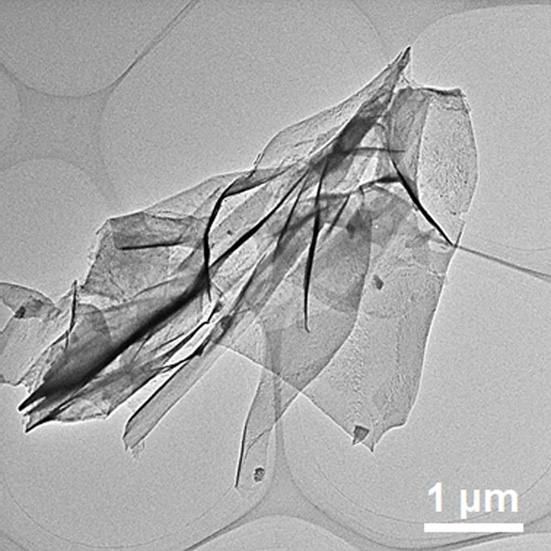

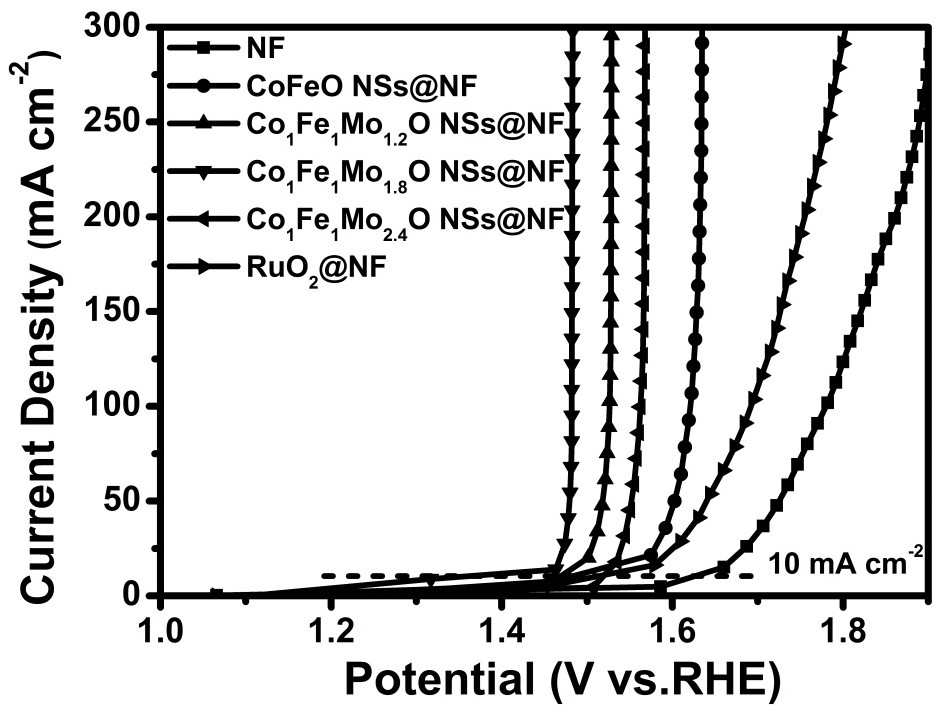

[0026] Co 1 Fe 1 Mo 1.2 Preparation of O NSs

[0027] First, 1 mmol of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), 1 mmol ferric nitrate nonahydrate (Fe(NO) 3 ) 2 ·9H 2 O), 5 mmol urea and 4 mmol NH 4 F, and 1.2 mmol of ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 7 O 24 ·4H 2 O) was added to 36 mL of ultrapure water, stirred until completely dissolved, where Co(NO 3 ) 2 ·6H 2 O, Fe (NO 3 ) 2 ·9H 2 O and (NH 4 ) 6 Mo 7 O 24 ·4H 2 O molar amount x / y / z ratio is 1:1:1.2.

[0028] Then, this solution and nickel foam as the base material were transferred into a 50 mL Teflon-lined stainless steel autoclave, which was sealed, heated at 180 °C for 10 h, and naturally cooled to room temperature. The product was washed several times with ultrapure water and absolute ethanol, vacuum dried at 60 °C, and finally annealed at 800 °C for 2 h. The resulting product is denoted as Co 1 Fe 1 Mo 1.2 O NSs@NF.

Embodiment 2

[0030] Co 1 Fe 1 Mo 1.8 Preparation of O NSs

[0031] First, 1 mmol of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), 1 mmol ferric nitrate nonahydrate (Fe(NO) 3 ) 2 ·9H 2 O), 5 mmol urea and 4 mmol NH 4 F, and 1.8 mmol of ammonium molybdate tetrahydrate ((NH 4 ) 6Mo 7 O 24 ·4H 2 O) was added to 36 mL of ultrapure water, stirred until completely dissolved, where Co(NO 3 ) 2 ·6H 2 O, Fe (NO 3 ) 2 ·9H 2 O and (NH 4 ) 6 Mo 7 O 24 ·4H 2 O molar amount x / y / z ratio is 1:1:1.8.

[0032] Then, this solution and nickel foam as the base material were transferred into a 50 mL Teflon-lined stainless steel autoclave, which was sealed, heated at 180 °C for 10 h, and naturally cooled to room temperature. The product was washed several times with ultrapure water and absolute ethanol, vacuum dried at 60 °C, and finally annealed at 800 °C for 2 h. The resulting product is denoted as Co 1 Fe 1 Mo 1.8 O NSs@NF.

Embodiment 3

[0034] Co 1 Fe 1 Mo 2.4 Preparation of O NSs

[0035] First, 1 mmol of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), 1 mmol ferric nitrate nonahydrate (Fe(NO) 3 ) 2 ·9H 2 O), 5 mmol urea and 4 mmol NH 4 F, and 2.4 mmol of ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 7 O 24 ·4H 2 O) was added to 36 mL of ultrapure water, stirred until completely dissolved, where Co(NO 3 ) 2 ·6H 2 O, Fe (NO 3 ) 2 ·9H 2 O and (NH 4 ) 6 Mo 7 O 24 ·4H 2 The 0 molar amount x / y / z ratio is 1:1:2.4.

[0036] Then, this solution and nickel foam as the base material were transferred into a 50 mL Teflon-lined stainless steel autoclave, which was sealed, heated at 180 °C for 10 h, and naturally cooled to room temperature. The product was washed several times with ultrapure water and absolute ethanol, vacuum dried at 60 °C, and finally annealed at 800 °C for 2 h. The resulting product is denoted as Co 1 Fe 1 Mo 2.4 O NSs@NF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com