Preparation method of porphyrin COF and carbon nitride composite material and application in photocatalytic degradation of organic dyes

A composite material and photocatalytic technology, which is applied in the field of porphyrin-based COF materials and graphite-phase carbon nitride composite materials, and semiconductor materials, can solve the problems of limiting the practical application of COF materials, harsh synthesis conditions, and high cost of COF materials, and achieve good results. Photocatalytic degradation of organic pollutants, low cost, and improved absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] g-C 3 N 4 Preparation: Put 15g of melamine in an alumina crucible, cover it, put it into a muffle furnace, heat at a rate of 10°C / min, and heat at 550°C for 1 hour under nitrogen protection to obtain 7.8g of light yellow powder.

[0039] 8%CuP-Ph-COF / g-C 3 N 4 Preparation: weigh 100mg synthetic g-C 3 N 4 , and 2.88g terephthalaldehyde, drop two drops of a mixed solution of o-dichlorobenzene and n-butanol (volume ratio 1:1) and 1 drop of 6M acetic acid solution, grind for 0.5h, then add 8mg CuTAPP, and then drop two drops of o-dichlorobenzene Mixed solution of chlorobenzene and n-butanol (1:1) and 1 drop of 6M acetic acid solution, continued to grind for 2 hours, then washed with chloroform, filtered, and dried to obtain 8% CuP-Ph-COF / g-C 3 N 4 ; Prepare 5% CuP-Ph-COF / g-C in the same way 3 N 4 , 6% CuP-Ph-COF / g-C 3 N 4 10%CuP-Ph-COF / g-C 3 N 4 and 20% CuP-Ph-COF / g-C 3 N 4 .

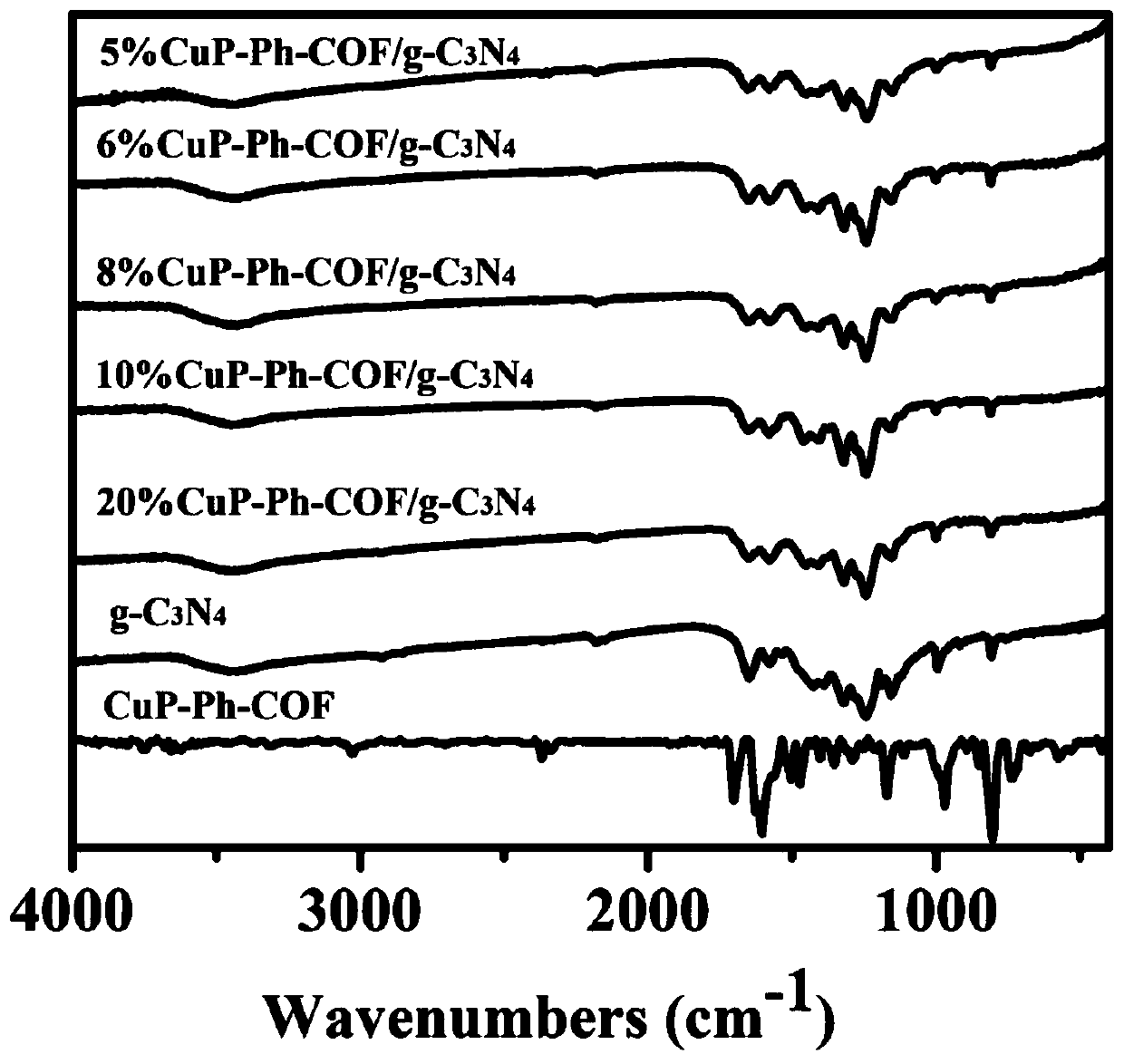

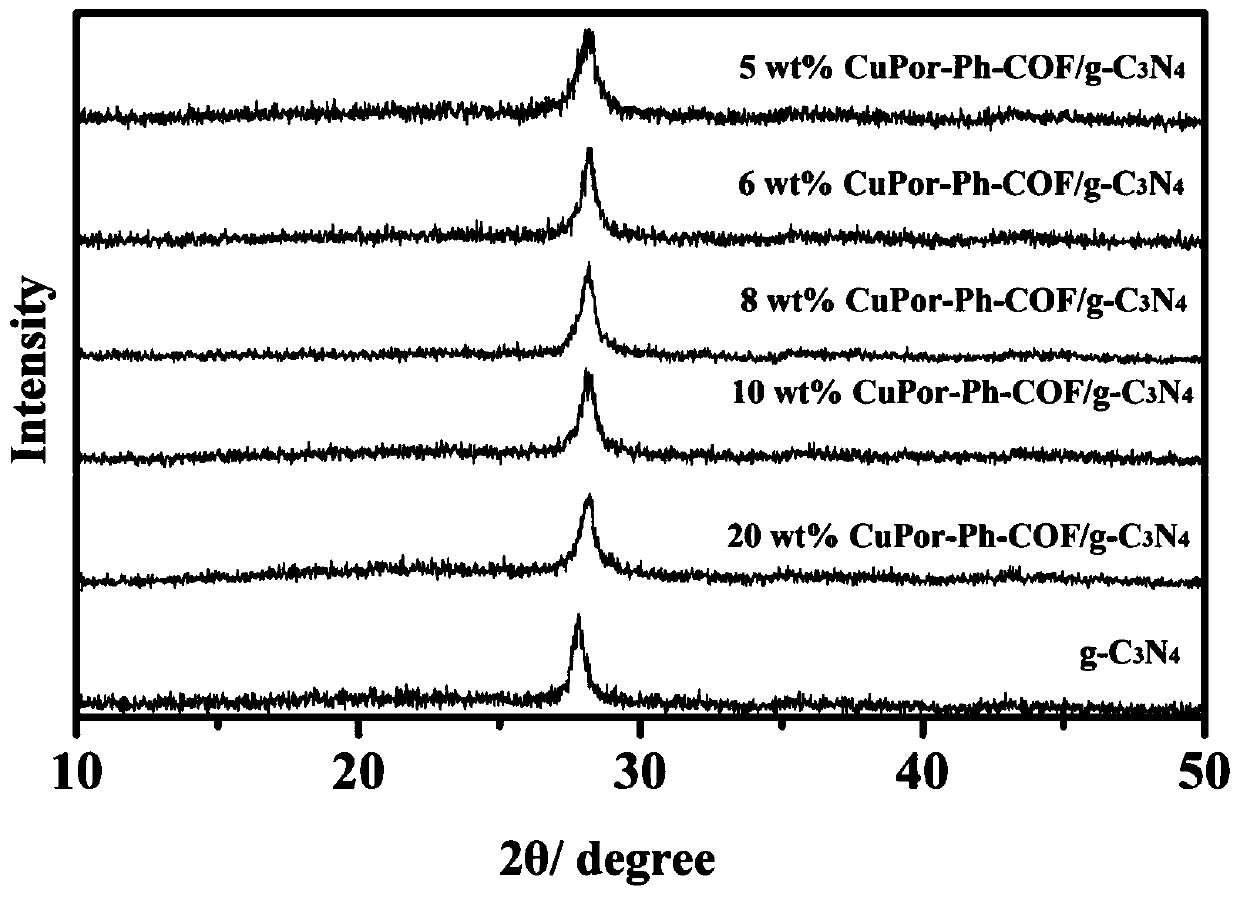

[0040] Such as figure 1 Shown, CuP-Ph-COF at 1620cm -1 There is a strong absorpt...

Embodiment 2

[0045] Photocatalytic degradation of Rhodamine B: In order to further explore the synthesis of CuP-Ph-COF / g-C 3 N 4 The performance of the composite material, a series of experiments were designed to verify the efficiency of its catalytic degradation of Rhodamine B.

[0046] Take 20mg catalyst (5%CuP-Ph-COF / g-C 3 N 4 , 6% CuP-Ph-COF / g-C 3 N 4 , 8% CuP-Ph-COF / g-C 3 N 4 , 10% CuP-Ph-COF / g-C 3 N 4 , 20% CuP-Ph-COF / g-C 3 N 4 , CuP-Ph-COF, g-C 3 N 4 ), then add 50mL (10mg / L) rhodamine B aqueous solution, and ultrasonically ensure that the catalyst is added and dispersed completely. After dark reaction adsorption reached adsorption equilibrium for one hour, the rhodamine B solution was irradiated with a xenon lamp light source with a 400nm filter, and the reaction solution was taken every 15 minutes, centrifuged, and the supernatant was taken to measure its absorbance.

[0047] Such as Figure 5 Shown, composite 5%, 6%, 8%, 10%, 20% CuP-Ph-COF / g-C 3 N 4 The ability o...

Embodiment 3

[0049] Photocatalytic degradation of rhodamine B pH condition screening: take 20mg 8% CuP-Ph-COF / g-C 3 N 4 , then add 50mL (10mg / L) rhodamine B aqueous solution, adjust the pH of the solution to 1, 2, 3, 4, 7, 10 with 1mol / L hydrochloric acid solution and sodium hydroxide solution, and ultrasonically ensure that the catalyst is completely dispersed. After the dark reaction adsorption reached adsorption equilibrium for one hour, the rhodamine B solution was irradiated with a xenon light source with a 400nm filter, and the reaction solution was taken every 5 minutes, centrifuged, and the supernatant was taken to measure its absorbance and monitor the reaction progress.

[0050] Such as Figure 6 As shown, regardless of acidic or alkaline conditions, 20mg 8% CuP-Ph-COF / g-C 3 N 4 The efficiency of photocatalytic degradation of Rhodamine B is higher than that of neutral conditions, and 20mg 8% CuP-Ph-COF / g-C in pH 3 solution 3 N 4 It showed the best catalytic performance, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com