System and method for grading purification of potassium salt and sodium salt in fly ash water washing solution

A water washing, potassium and sodium technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, heating water/sewage treatment, etc., can solve the problems affecting the continuous operation of the MVR system, the difficulty in establishing a balance between the old and the new system, and the low purity of potassium chloride. and other problems, to achieve the effect of promoting continuous and stable operation, reducing the cost of fly ash disposal, and realizing recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

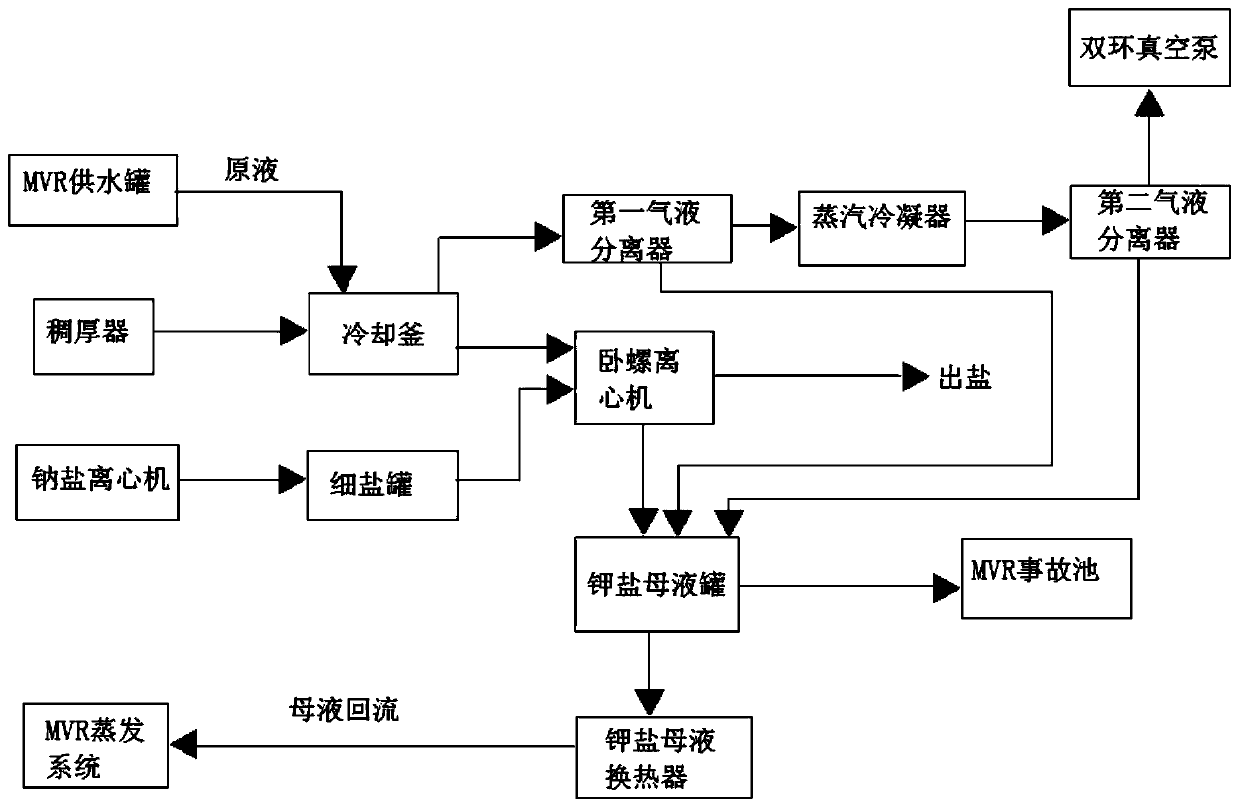

[0032] Such as figure 1 Shown, a kind of fly ash water washing liquid potassium sodium salt separation and purification system comprises thickener, cooling kettle, decanter centrifuge, potassium salt mother liquor tank, potassium salt mother liquor heat exchanger, MVR evaporation system connected in sequence, said The cooling kettle is also connected with a vacuum pumping system and an MVR water supply tank, and the decanter centrifuge is also connected with a fine salt tank, and the fine salt tank is connected with a sodium salt centrifuge.

[0033] The vacuum pumping system includes a first gas-liquid separator, a steam condenser, a second gas-liquid separator and a double-ring vacuum pump connected in sequence, and the first gas-liquid separator is connected to the cooling tank.

[0034] The vacuum system ensures that the cooling kettle is cooled under vacuum conditions, and potassium chloride crystals are obtained through decanter centrifuge separation, and the mother liqu...

Embodiment 2

[0044] The present embodiment utilizes the method for the described system quality separation and purification of potassium and sodium in the fly ash washing liquid, comprising the following steps:

[0045] First pump the supernatant in the thickener into the cooling tank, then pump the unsaturated brine in the MVR water supply tank into the cooling tank to wash and salt the supernatant in the thickener, through vacuum flash evaporation and The combined cooling method of circulating cooling water realizes rapid cooling and crystallization of materials to precipitate potassium chloride crystals, and then all enter the decanter centrifuge for separation to obtain potassium chloride crystals and potassium chloride mother liquor, and the potassium chloride mother liquor enters the potassium salt The mother liquor tank is then heated to 100°C through the potassium salt mother liquor heat exchanger, and returned to the MVR evaporation system. At the same time, when the fine salt enr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com