Low-warpage PPR-based composite wire for 3D printing, and preparation method thereof

A 3D printing and 3D printer technology, applied in the field of 3D printing materials and their preparation, can solve the problems of insufficient types of 3D printing consumables, and achieve the effects of broadening the field of 3D printing materials, reducing warping deformation, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

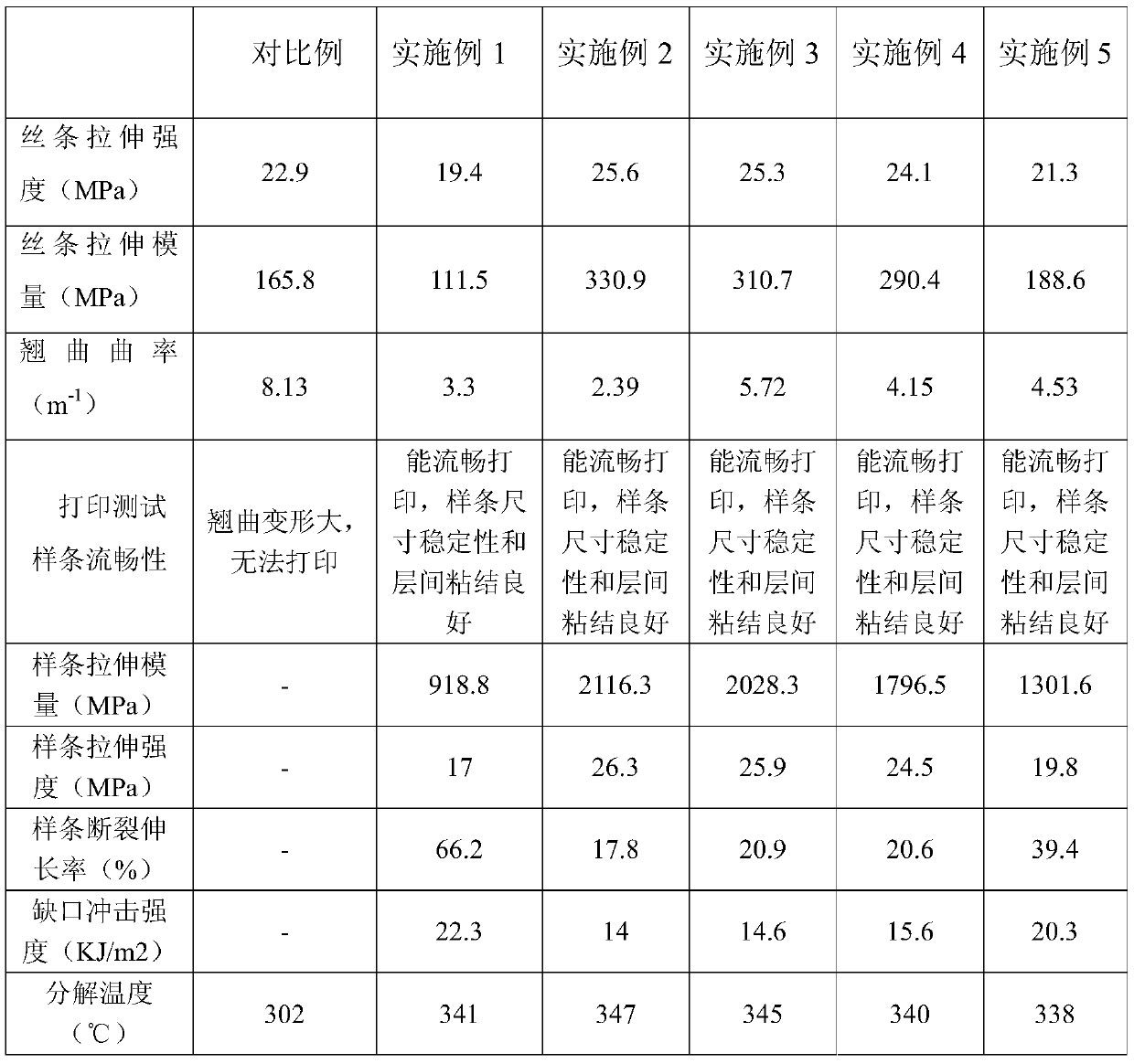

Examples

Embodiment 1

[0030] 40 parts by mass of random copolymerized polypropylene, 29.9 parts of glass fiber, 30 parts of EPDM rubber and 0.1 part of antioxidant 1010 were put into a high-speed kneader and mixed for 5 minutes to obtain a premix; The mixed materials are put into the twin-screw extruder for blending and extrusion, and then cooled and pelletized to obtain composite material pellets. The processing temperature of the twin-screw extruder is divided into eight sections, which are successively set as: 160°C, 170°C, 180°C, 190°C, 190°C, 190°C, 190°C and 190°C, the head temperature is 190°C, the screw speed is 190r / min, and the feeding speed is 10r / min; Extrude, stretch, cool and wind in the extruder to obtain a PPR-based composite filament with a diameter of 1.75mm for 3D printing. The processing temperature of the consumable extruder is 180 from the hopper to the head. ℃, 210℃, 210℃ and 200℃, the extrusion speed is 700r / min, and the pulling speed is 80r / min.

[0031] The obtained PPR-b...

Embodiment 2

[0033]42.4 parts by mass of random copolymerized polypropylene, 45 parts of glass fiber, 12 parts of EPDM rubber and 0.6 part of antioxidant 1010 were put into a high-speed kneader and mixed for 10 minutes to obtain a premix; The mixed materials are put into the twin-screw extruder for blending and extrusion, and then cooled and pelletized to obtain composite material pellets. The processing temperature of the twin-screw extruder is divided into eight sections, which are successively set as: 160°C, 170°C, 180°C, 190°C, 190°C, 190°C, 190°C and 190°C, the head temperature is 190°C, the screw speed is 190r / min, and the feeding speed is 10r / min; Extrude, stretch, cool and wind in the extruder to obtain a PPR-based composite filament with a diameter of 1.75mm for 3D printing. The processing temperature of the consumable extruder is 180 from the hopper to the head. ℃, 210℃, 210℃ and 200℃, the extrusion speed is 700r / min, and the pulling speed is 80r / min.

[0034] The obtained PPR-b...

Embodiment 3

[0036] 60 parts by mass of random copolymerized polypropylene, 29 parts of glass fibers, 10 parts of EPDM rubber and 1.0 parts of antioxidant 1010 were put into a high-speed kneader and mixed for 6 minutes to obtain a premix; The mixed materials are put into the twin-screw extruder for blending and extrusion, and then cooled and pelletized to obtain composite material pellets. The processing temperature of the twin-screw extruder is divided into eight sections, which are successively set as: 160°C, 170°C, 180°C, 190°C, 190°C, 190°C, 190°C and 190°C, the head temperature is 190°C, the screw speed is 190r / min, and the feeding speed is 10r / min; Extrude, stretch, cool and wind in the extruder to obtain a PPR-based composite filament with a diameter of 1.75mm for 3D printing. The processing temperature of the consumable extruder is 180 from the hopper to the head. ℃, 210℃, 210℃ and 200℃, the extrusion speed is 700r / min, and the pulling speed is 80r / min.

[0037] The obtained PPR-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com