Graphene in-situ grafted polyester film and preparation method thereof

A technology of grafting polyester and graphene, applied in the field of polyester film processing, can solve the problems of antistatic attenuation, affecting surface finish, poor compatibility, etc., to improve electrical conductivity, improve hydrophobicity, oil repellency and stain resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

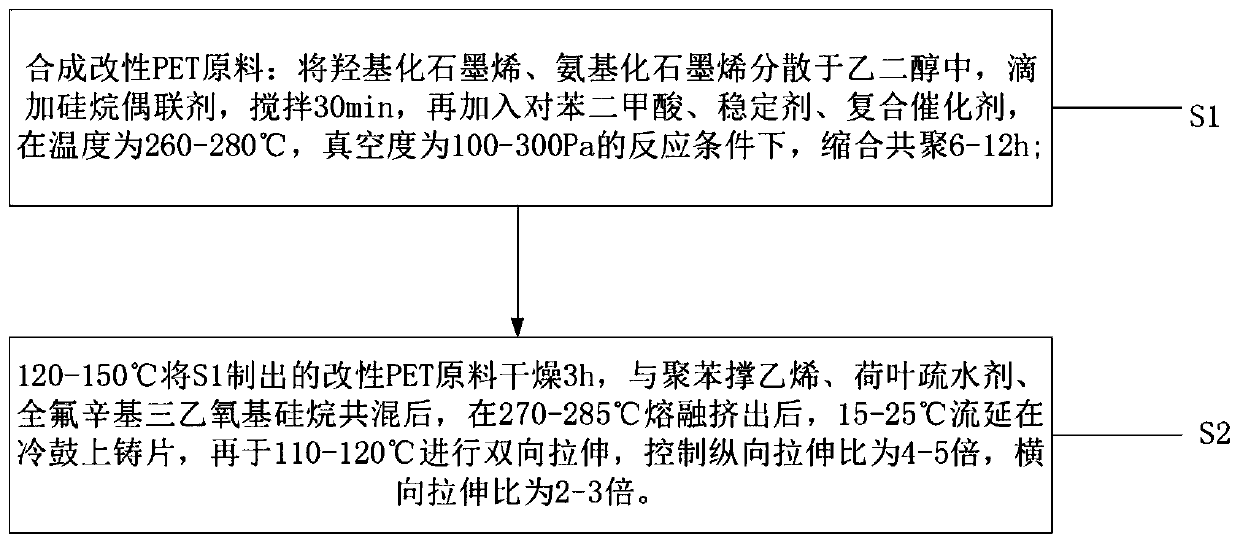

Method used

Image

Examples

Embodiment 1

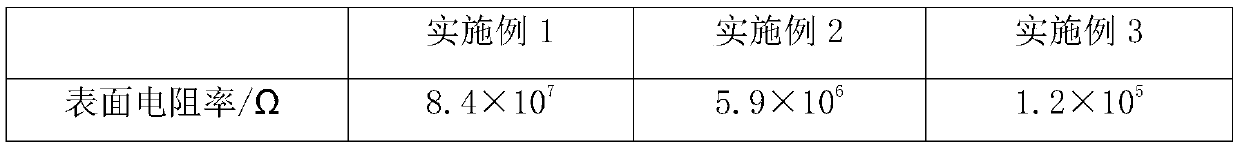

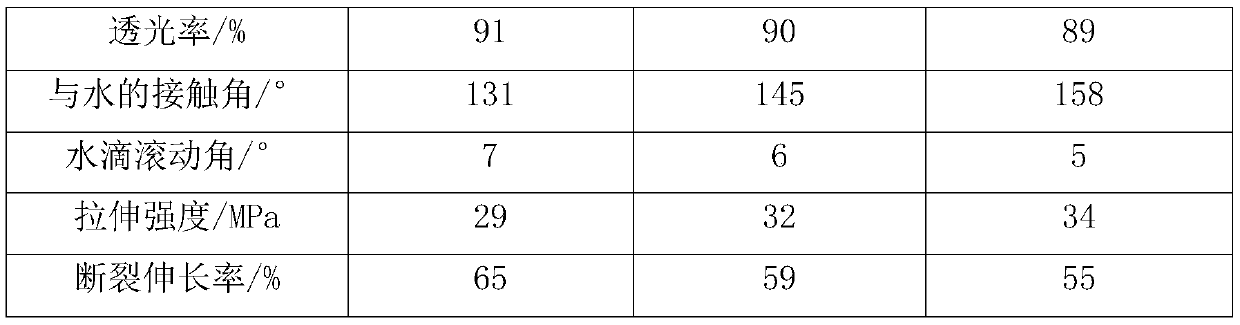

[0018] Embodiment 1 prepares graphene in situ graft polyester film

[0019] S1: Synthesis of modified PET raw materials: disperse 6% hydroxylated graphene and 4% aminated graphene in 36% ethylene glycol by mass percentage, add 0.5% silane coupling agent dropwise, stir for 30 minutes, and then add 52% Terephthalic acid, 0.5% triphenyl phosphite, 1% composite catalyst, the composite catalyst is composed of antimony methanol and thionyl chloride in a mass ratio of 1:0.5, and the reaction conditions are at a temperature of 260°C and a vacuum of 150Pa Next, condensation copolymerization for 6h;

[0020] S2: Dry the modified PET raw material prepared in S1 at 120°C for 3 hours, and blend it with polyphenylene vinylene, lotus leaf hydrophobic agent, and perfluorooctyltriethoxysilane at a mass ratio of 100:1:1:1. , after melt-extruding at 270°C, casting on a cold drum at 15°C, and then biaxially stretching at 110°C, controlling the longitudinal stretching ratio to 4 times and the tra...

Embodiment 2

[0021] Embodiment 2 prepares graphene in situ graft polyester film

[0022] S1: Synthesis of modified PET raw materials: Disperse 8% hydroxylated graphene and 5% aminated graphene in 37% ethylene glycol by mass percentage, add 0.8% silane coupling agent dropwise, stir for 30 minutes, and then add 47% Terephthalic acid, 1% triphenyl phosphite, 1.2% composite catalyst, the composite catalyst is composed of antimony methanol and thionyl chloride in a mass ratio of 1:0.6, and the reaction conditions are at a temperature of 270°C and a vacuum of 200Pa Next, condensation copolymerization 8h;

[0023] S2: Dry the modified PET raw material produced in S1 at 130°C for 3 hours, and blend it with polyphenylene vinylene, lotus leaf hydrophobic agent, and perfluorooctyltriethoxysilane at a mass ratio of 100:2:2:1 , after melt-extruding at 280°C, casting on a cold drum at 20°C, and then biaxially stretching at 110°C, controlling the longitudinal stretching ratio to 4 times and the transver...

Embodiment 3

[0024] Embodiment 3 prepares graphene in situ graft polyester film

[0025] S1: Synthesis of modified PET raw materials: Disperse 10% hydroxylated graphene and 6% aminated graphene in 38% ethylene glycol by mass percentage, add 1% silane coupling agent dropwise, stir for 30 minutes, and then add 42% Terephthalic acid, 1.5% triphenyl phosphite, 1.5% composite catalyst, the composite catalyst is composed of antimony methanol and thionyl chloride at a mass ratio of 1:0.8, and the reaction conditions are at a temperature of 280°C and a vacuum of 200Pa Next, condensation copolymerization for 12h;

[0026] S2: Dry the modified PET raw material produced in S1 at 140°C for 3 hours, and blend it with polyphenylene vinylene, lotus leaf hydrophobic agent, and perfluorooctyltriethoxysilane at a mass ratio of 100:2.5:3:1.5 , after melt-extruding at 285°C, casting on a cold drum at 25°C, and then biaxially stretching at 120°C, controlling the longitudinal stretch ratio to 5 times and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com