Production technology of miconazole nitrate vaginal tablets

A miconazole nitrate, production process technology, applied in the direction of pill delivery, organic active ingredients, diseases, etc., can solve the problems of low efficiency of the pharmaceutical process, reduce the content of defective products, improve manufacturing efficiency, and ensure product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

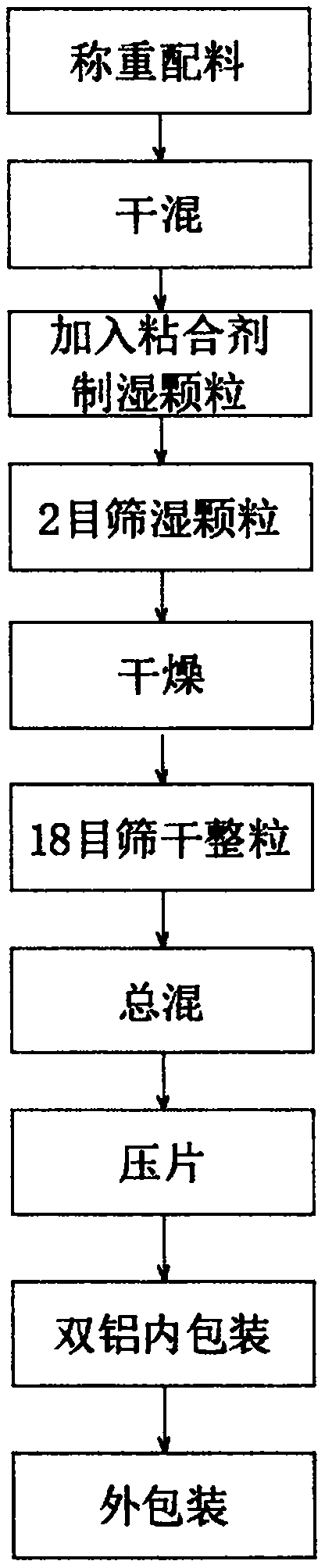

[0034] Such as figure 1 Shown, the embodiment of the present invention provides miconazole nitrate vaginal tablet production process, comprises the steps:

[0035] Sp1 weighing ingredients: pass miconazole nitrate and microcrystalline cellulose through a 100-mesh sieve for later use, and weigh miconazole nitrate, microcrystalline cellulose, starch, and crospovidone according to the confidential process prescription;

[0036] Sp2 dry mixing: Mix the weighed microcrystalline cellulose and miconazole nitrate for 6 minutes to make them uniform, add an appropriate amount of 8% starch slurry, and mix for 3 minutes to make a soft material;

[0037] Sp3 wet granules: pass the soft material through a 2-mesh sieve to make wet granules;

[0038] Sp4 drying: Vacuumize the wet granules into fluidized bed drying, and dry at 60°C;

[0039] Sp5 granulation: pass the dried granules through an 18-mesh regulating sieve drum;

[0040] Sp6 blending: add the sized granules to the prescribed amou...

Embodiment 2

[0045] Such as figure 1 As shown, the embodiment of the present invention provides miconazole nitrate vaginal tablet production process, the operation process of weighing: miconazole nitrate, microcrystalline cellulose are crossed 100 mesh sieves for subsequent use, accurately weigh respectively corn starch, The processes of microcrystalline cellulose, crospovidone, miconazole nitrate, dry mixing and wet granulation are connected together. The dry mixing process first prepares the binder: dissolve the prescribed amount of corn starch in purified water to prepare After slurring 8% cornstarch the dry powder is blended:

[0046] Adding order: microcrystalline cellulose, miconazole nitrate, mixed to obtain dry powder;

[0047]Process steps: use a vacuum pump to suck the weighed raw and auxiliary materials into the wet mixing granulator in sequence, set the stirring knife speed: 120rpm, the granulating knife speed: 500rpm; dry mixing time: 360 seconds, add binder: use The fast-lo...

Embodiment 3

[0049] Such as figure 1 As shown, the embodiment of the present invention provides the miconazole nitrate vaginal tablet production process, the weighing process adopts two people to weigh, one person weighs, and one person checks, the moisture that is finally dried by the drying process is no more than 3%, and the granulation process needs to be screened. Damaged, confirm the mesh number of the sieve cylinder, the quality inspection of the total blend includes product shape, moisture, particle content and theoretical tablet weight, the weight difference of the tableting process is ±4%, the packaging process checks the airtightness of the package, the batch number printing, and the appearance of damage And weight parameters, wet mixing granulator with signal GM500 is used for dry mixing and wet granulation, fluidized bed model FBD400 is used for drying, lifting transfer machine model LHM-500 is used for granulation, and model The hopper mixer is BDV-1800, the tablet is pressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com