Preparation method of vitamin A acetate microcapsules

A technology of acetate and vitamin, which is applied in the field of preparation of vitamin A acetate microcapsules, which can solve the problems of uniform starch packaging, excessive density difference, and fast sinking of microcapsules, and achieve short drying time and low loss rate. Low, good embedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

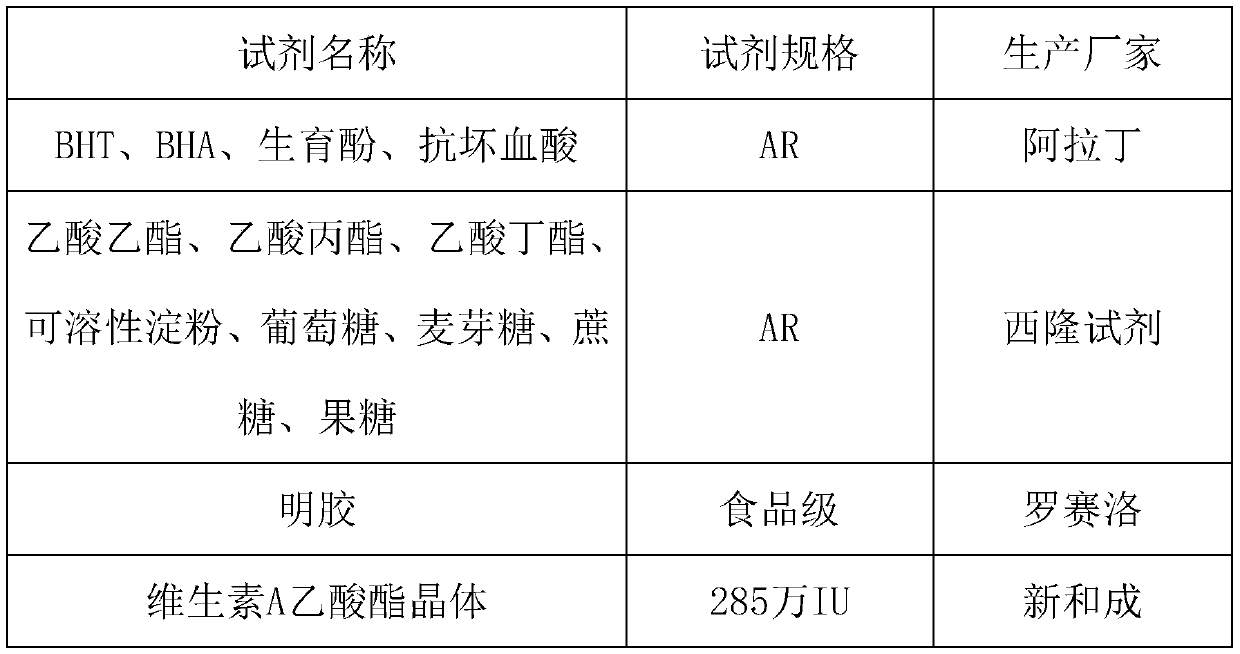

[0045] (1) Weigh 0.5g of BHT and 20g of vitamin A acetate crystals, place them in a 100mL single-mouth bottle, and after nitrogen replacement, melt the vitamin A acetate crystals at 60°C for use;

[0046] (2) Weigh 64g of gelatin with a freezing strength of 40, 16g of glucose (the mass ratio of gelatin to sugar is 4:1), 54.1g of deionized water, mix gelatin, sugar, and deionized water and heat to dissolve at 60°C;

[0047] (3) Cut the gelatin-sugar-water solution with a high-speed shearing machine, drop the melted oil of vitamin A acetate in step (1) into the aqueous solution within 30 minutes, and continue to cut for 15 minutes after the dropping, and maintain the dispersion temperature at At 60°C, an emulsion was obtained with a solid content of 65%, and the mass ratio of the wall material to the core material used was 3.9:1;

[0048](4) Weigh 100g starch and 900g ethyl acetate, put them in a 2L glass flask, prepare 10% starch / ethyl acetate slurry, stir the slurry evenly wit...

Embodiment 2

[0051] (1) Weigh 1.0g of BHA and 50g of vitamin A acetate crystals, place them in a 100mL single-mouth bottle, and after nitrogen replacement, melt the vitamin A acetate crystals at a temperature of 55°C for use;

[0052] (2) Weigh 48g of gelatin with a freezing strength of 60, 16g of glucose (the mass ratio of gelatin to sugar is 3:1), 38.3g of deionized water, mix gelatin, sugar, and deionized water and heat to dissolve at 55°C;

[0053] (3) Cut the gelatin-sugar-water solution with a high-speed shearing machine, drop the melted oil of vitamin A acetate in step (1) into the aqueous solution within 75 minutes, continue to cut for 15 minutes after the addition, and maintain the dispersion temperature at 55°C to obtain an emulsion with a solid content rate of 75%, and the mass ratio of the wall material to the core material used is 1.3:1;

[0054] (4) Weigh 50g starch and 950g propyl acetate, put them in a 2L glass flask, prepare 5% starch / ethyl acetate slurry, stir the slurry ...

Embodiment 3

[0057] (1) Weigh 1.0 g of tocopherol and 20 g of vitamin A acetate crystals, place them in a 100 mL single-mouth bottle, and after nitrogen replacement, melt the vitamin A acetate crystals at a temperature of 65°C for use;

[0058] (2) Weigh 80g of gelatin with a freezing strength of 50, 20g of fructose (the mass ratio of gelatin to sugar is 4:1), 99g of deionized water, mix gelatin, sugar, and deionized water and heat to dissolve at 65°C;

[0059] (3) Cut the gelatin-sugar-water solution with a high-speed shearing machine, drop the melted oil of vitamin A acetate in step (1) into the aqueous solution within 15 minutes, continue to cut for 15 minutes after the addition, and maintain the dispersion temperature at At 65°C, an emulsion was obtained with a solid content of 55%, and the mass ratio of the wall material to the core material used was 4.8:1;

[0060] (4) Weigh 200g starch and 800g butyl acetate, put them in a 2L glass flask, prepare 20% starch / ethyl acetate slurry, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com