A stimulus-responsive clean fracturing fluid and its preparation method

A clean fracturing fluid and stimuli-response technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as environmental pollution, strong fluid loss, large dosage, etc., and achieve flexible performance control and good thickening performance, easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

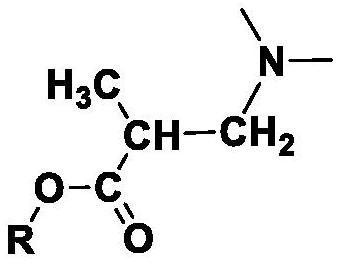

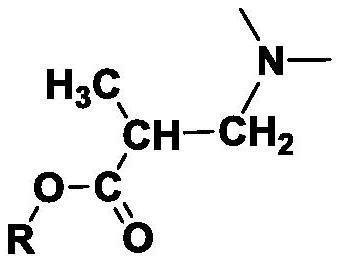

[0019] 1) react lauryl methacrylate and dimethylamine aqueous solution at a molar ratio of 1:1.5 at room temperature for 24 hours, and remove excess dimethylamine by rotary evaporation to obtain a long-chain tertiary amine; 2) use 3% long-carbon Chain tertiary amines are used as thickeners. Add HCl to completely protonate long-chain tertiary amines to obtain a clear and transparent thickener solution, and then add 1% sodium salicylate to obtain viscoelastic surfactant cleaning fracturing fluid. The temperature resistance of clean fracturing fluid reaches above 60°C. When NaOH is added to the clean fracturing fluid, the thickener will be deprotonated, the clean fracturing fluid will automatically break the gel, and the viscosity will drop below 5mPa.s. The tertiary amine precipitates out of solution and can be reconstituted with clean fracturing fluid after separation.

Embodiment 2

[0021] 1) React tetradecyl methacrylate and dimethylamine aqueous solution at a molar ratio of 1:2 at room temperature for 24 hours, and remove excess dimethylamine by rotary evaporation to obtain a long-chain tertiary amine; 2) use 4% long-carbon Chain tertiary amine is used as thickener, add HCl to completely protonate long carbon chain tertiary amine to obtain clear and transparent thickener solution, then add 1.5% sodium p-toluenesulfonate to obtain viscoelastic surfactant cleaning fracturing fluid , Clean fracturing fluid can resist temperature above 90°C. When NaOH is added to the clean fracturing fluid, the thickener will be deprotonated, the clean fracturing fluid will automatically break the gel, and the viscosity will drop below 5mPa.s. The tertiary amine precipitates out of solution and can be reconstituted with clean fracturing fluid after separation.

Embodiment 3

[0023] 1) React octadecyl methacrylate and dimethylamine aqueous solution at a molar ratio of 1:3 at room temperature for 24 hours, and remove excess dimethylamine by rotary evaporation to obtain a long-chain tertiary amine; 2) use 5% long-carbon Chain tertiary amines are used as thickeners. Add HCl to complete the protonation of long carbon chain tertiary amines to obtain a clear and transparent thickener solution, and then add 2% sodium salicylate to obtain viscoelastic surfactant cleaning fracturing fluid. The temperature resistance of the clean fracturing fluid can reach above 90°C. When NaOH is added to the clean fracturing fluid, the thickener will be deprotonated, the clean fracturing fluid will automatically break the gel, and the viscosity will drop below 5mPa.s. The tertiary amine precipitates out of solution and can be reconstituted with clean fracturing fluid after separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com