Method for catalyzing benzylation reaction by means of lignin-based solid acid

A technology of lignin-based and sodium lignosulfonate, which is applied in the field of lignin-based solid acid catalyzed benzylation reaction, can solve the problems of catalyst activity, water resistance, reusability and environmental friendliness being difficult to take into account, and achieves cost Low, source-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 strong Preparation of Acidic Lignin-Based Solid Acid A

[0020] at 5°C·min -1 Heating rate, 80mL·min -1 flow rate N 2 Under the atmosphere, the dried sodium lignosulfonate (SLS) was carbonized in a tube furnace at 400 °C for 1 h, and cooled to room temperature to obtain lignin carbon SLC 400,1 ; by 10mL 浓硫酸 / g 木质素碳 The ratio of lignin carbon to SLC 400,1 and concentrated sulfuric acid in a three-necked flask, N 2 400r·min under atmosphere -1 Stir mechanically, react at 150°C for 10 hours, add 50mL of hot water above 80°C to filter, wash with hot water above 80°C until neutral, and dry in a vacuum oven at 50°C for 4 hours to obtain strong Acidic lignin-based solid acid A.

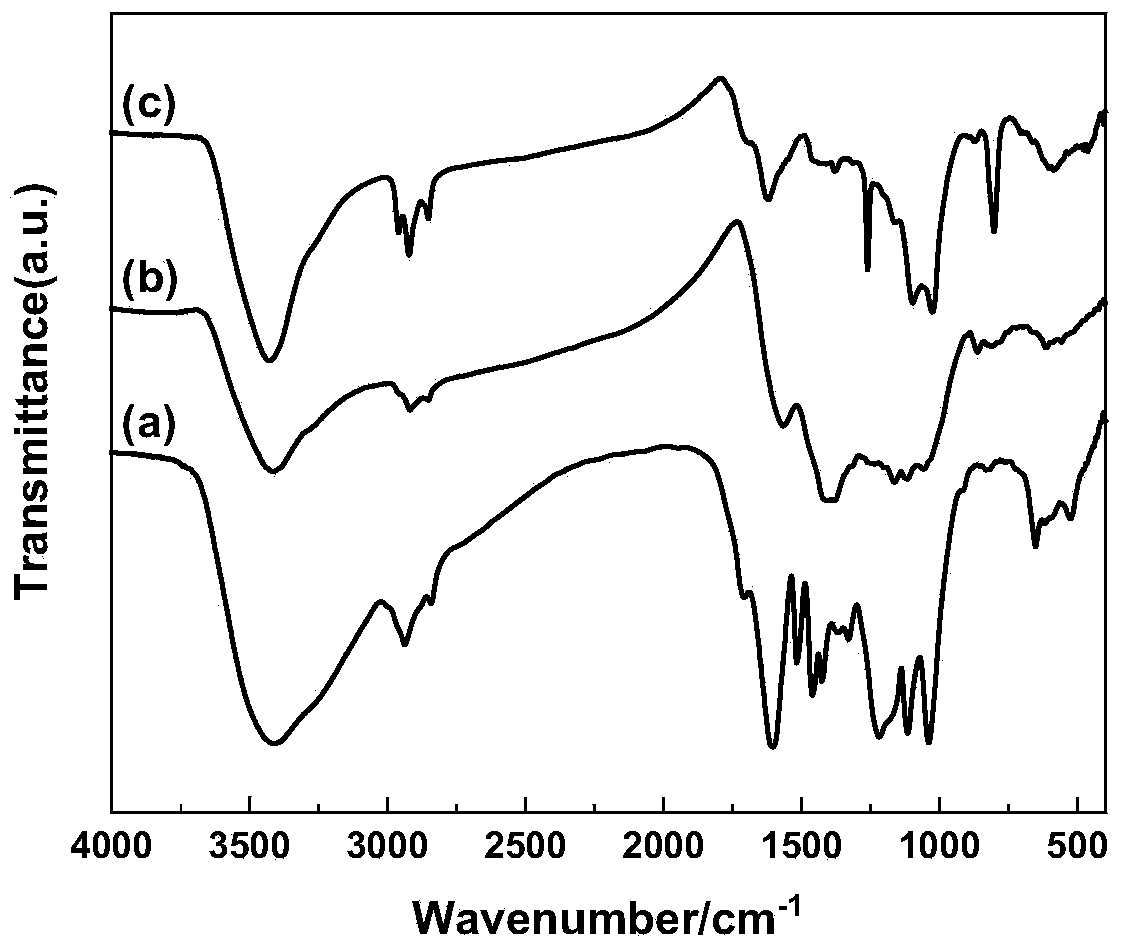

[0021] attached figure 1 The indicated FT-IR(KBr,v / cm -1 ) spectrum, SLS at 3405cm -1 The broad band observed at is attributed to the -OH group hydrogen-bonded to an adjacent oxygen or sulfonic acid; 2939cm -1 and 2839cm -1 SLS-CH 2 - stretching vibration; 1715cm -1 Indicat...

Embodiment 2

[0024] according to n 苯环化合物 :n 苯甲醇 =10 feed ratio Get p-xylene and benzyl alcohol in the reaction flask, then press 2.5mL 苯甲醇 / g 催化剂 The consumption of dropping into the strong prepared in embodiment 1 Acidic lignin-based solid acid catalyst A was reacted with magnetic stirring at 150° C. for 2 hours. After the reaction was completed, it was cooled and centrifuged, and the upper organic phase was taken for gas chromatography analysis. The catalytic results are shown in Table 1.

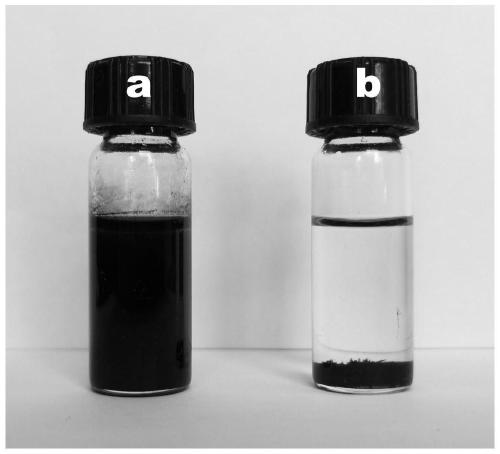

[0025] attached image 3 Shown is the macroscopic state diagram of the system after the catalytic reaction and centrifugation in Example 2, and the catalyst A can be effectively separated by centrifugation after the reaction.

Embodiment 3

[0027] according to n 苯环化合物 :n 苯甲醇 =10 feed ratio Get p-xylene and benzyl alcohol in the reaction flask, then press 2.5mL 苯甲醇 / g 催化剂 The consumption of dropping into the strong prepared in embodiment 1 Acidic lignin-based solid acid catalyst A was reacted with magnetic stirring at 150°C for 0.15h. After the reaction was completed, it was cooled and centrifuged, and the upper organic phase was taken for gas chromatography analysis. The catalytic results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com