Synthesis method of N-methyl-1,2-benzenediamine dihydrochloride

A technology of methyl-o-phenylenediamine hydrochloride and methyl-o-phenylenediamine, which is applied in the field of synthesizing intermediates of the antihypertensive drug tesamitan, can solve the problems of difficult product quality assurance, low purity of o-diphenylamine, Problems such as low utilization rate, to achieve the effect of improving utilization rate, less impurities, and high preparation purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

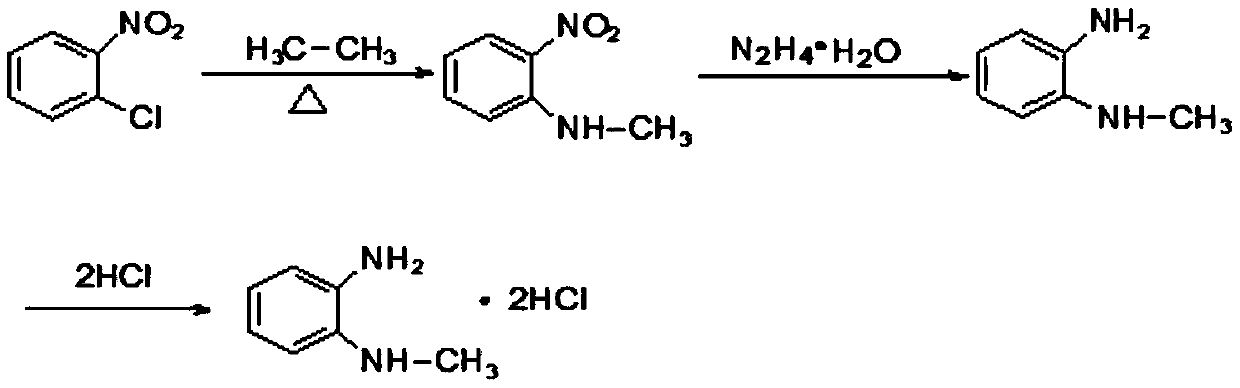

[0033] Add 200g of o-chloronitrobenzene and 197g of monomethylamine aqueous solution into a 1L autoclave, seal it, pressurize it with nitrogen to 0.5MPa, start to raise the temperature slowly, when T=90°C, stop heating, the reaction enters a spontaneous state, exotherm , the temperature continues to rise (the highest temperature can reach 110°C, and the maximum pressure is 1.2MPa). When the temperature no longer rises, continue to raise the temperature to 120°C, and keep the temperature for 5h. After the reaction was finished, the temperature was lowered, the layers were separated, and the lower oil phase was taken to obtain 190 g of N-methyl-o-nitroaniline.

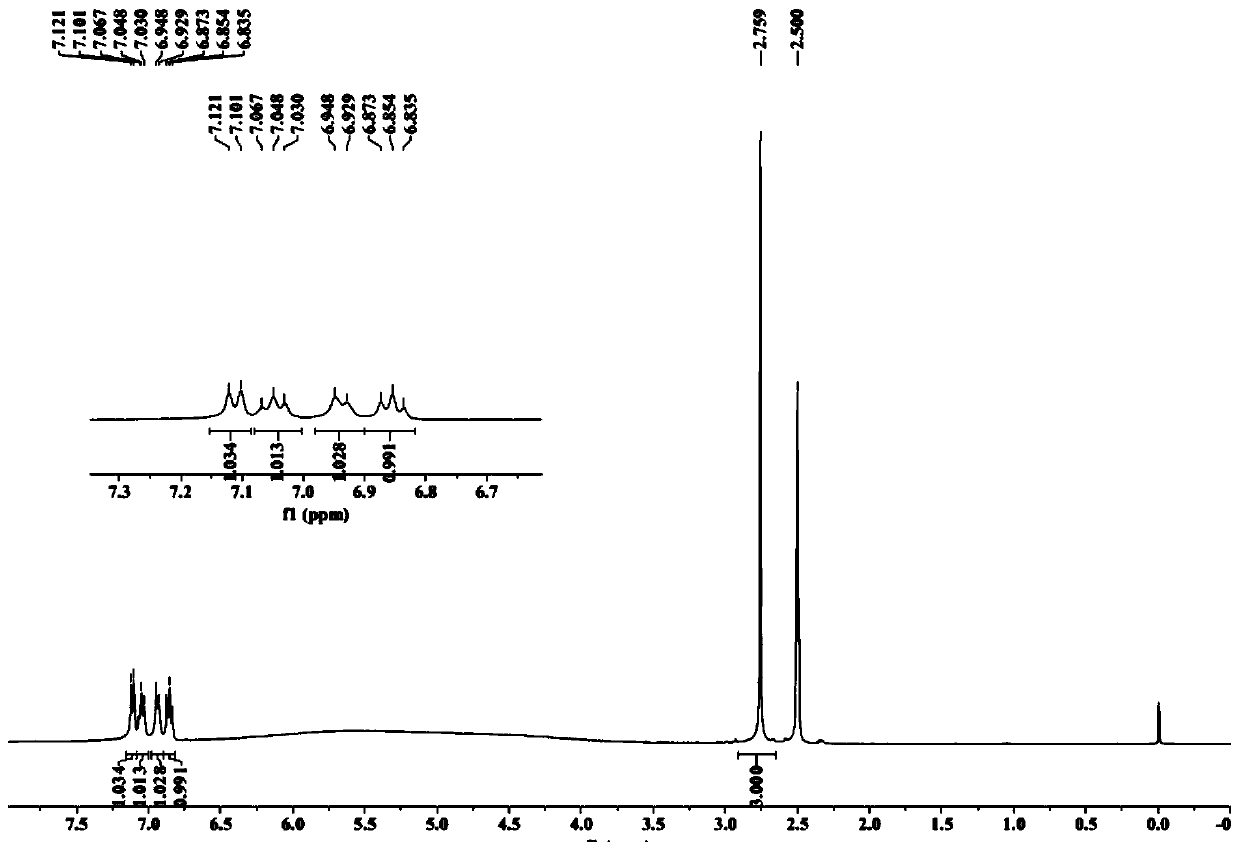

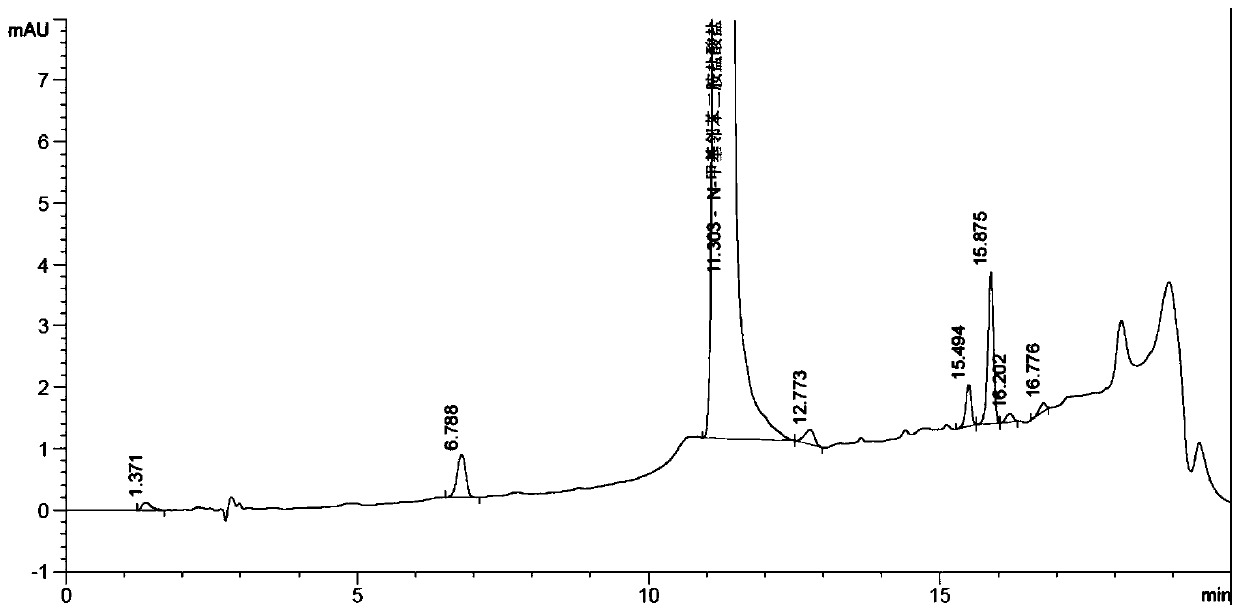

[0034] Add 120g of ethanol and 100g of N-methyl-o-nitroaniline to a 1L reaction flask in turn, start stirring, raise the temperature to 70-75°C, keep a slight reflux, slowly add hydrazine hydrate dropwise, after the addition is complete, keep it warm at 80°C Reaction 20h. After the reaction was finished, filter with suc...

Embodiment 2

[0037] Add 200g of o-chloronitrobenzene and 197g of monomethylamine aqueous solution into a 1L autoclave, seal it, pressurize it with nitrogen to 0.5MPa, start to raise the temperature slowly, when T=90°C, stop heating, the reaction enters a spontaneous state, exotherm , the temperature continues to rise (the highest temperature can reach 110°C, and the maximum pressure is 1.2MPa). When the temperature no longer rises, continue to raise the temperature to 120°C, and keep the temperature for 5h. After the reaction was finished, the temperature was lowered, the layers were separated, and the lower oil phase was taken to obtain 190 g of N-methyl-o-nitroaniline.

[0038] Add 120g of ethanol, 100g of N-methyl o-nitroaniline, 7g of FeCl to the 1L reaction flask 3 , 7g of activated carbon, start stirring, raise the temperature to 70-75°C, keep a slight reflux, slowly add hydrazine hydrate dropwise to it, after the addition is complete, keep the temperature at 80°C for 20h. After the...

Embodiment 3

[0041] Add 200g of o-chloronitrobenzene and 197g of monomethylamine aqueous solution into a 1L autoclave, seal it, pressurize it with nitrogen to 0.5MPa, start to raise the temperature slowly, when T=90°C, stop heating, the reaction enters a spontaneous state, exotherm , the temperature continues to rise (the highest temperature can reach 110°C, and the maximum pressure is 1.2MPa). When the temperature no longer rises, continue to raise the temperature to 120°C, and keep the temperature for 5h. After the reaction was finished, the temperature was lowered, the layers were separated, and the lower oil phase was taken to obtain 190 g of N-methyl-o-nitroaniline.

[0042] Add 120g of ethanol, 100g of N-methyl-o-nitroaniline, and 10g of loaded lacquer nickel finished product in sequence to a 1L reaction bottle, start stirring, raise the temperature to 70-75°C, keep a slight reflux, and slowly add hydrazine hydrate dropwise, After the dropwise addition, keep the reaction at 80°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com