Method for improving cohesiveness of high-protein nutrition bar by adding phospholipid vesicles

A nutritional bar and high-protein technology, which is applied to the functions of food ingredients, fat-containing food ingredients, food science, etc., can solve the problem of changing the surface hydrophilicity of MPC powder, the improvement of the cohesion of the system is not obvious, and the system is uniform Long time and other problems, to achieve the effect of good texture, high cohesion, not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: Preparation of high-protein nutrition bar

[0050] (1) Prepare milk protein concentrate: use bright skim milk as raw material, select polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 10kDa for ultrafiltration, and when the skim milk is concentrated to 1 / 3 of the initial volume, add After deionized water reaches the volume of the original skim milk, perform diafiltration, repeat the diafiltration step 3 times, and finally concentrate the sample 3 times to obtain the retentate.

[0051] (2) Preparation of MPC containing phospholipid vesicles: After adding 0.02% sodium azide to the obtained retentate to inhibit the growth of microorganisms, weigh a certain amount of soybean phospholipids, add deionized water to it, and configure it into The phospholipid solution with a mass concentration of 8% was stirred at room temperature for 3 hours to fully hydrate the phospholipids. Homogenize the fully hydrated phospholipid solution twice a...

Embodiment 2

[0054] Example 2: Preparation of milk protein concentrates with different phospholipid contents

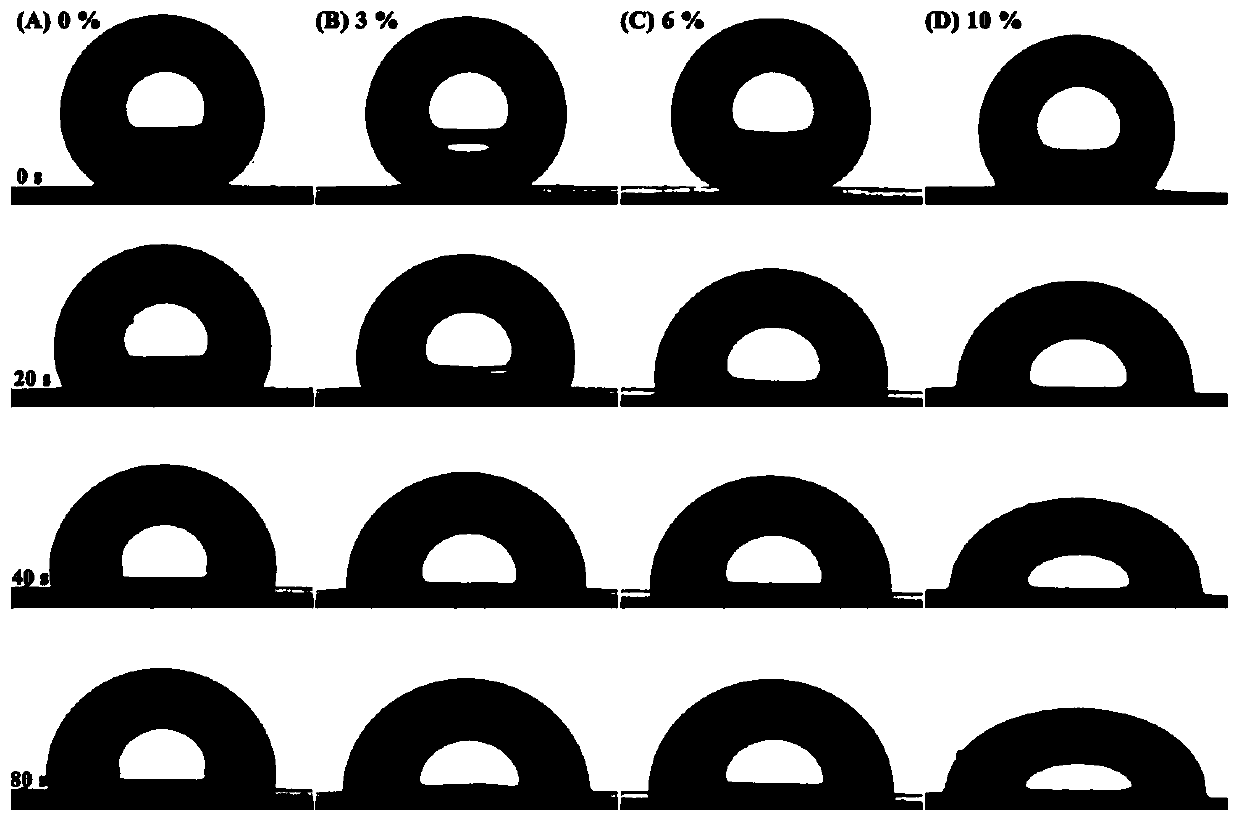

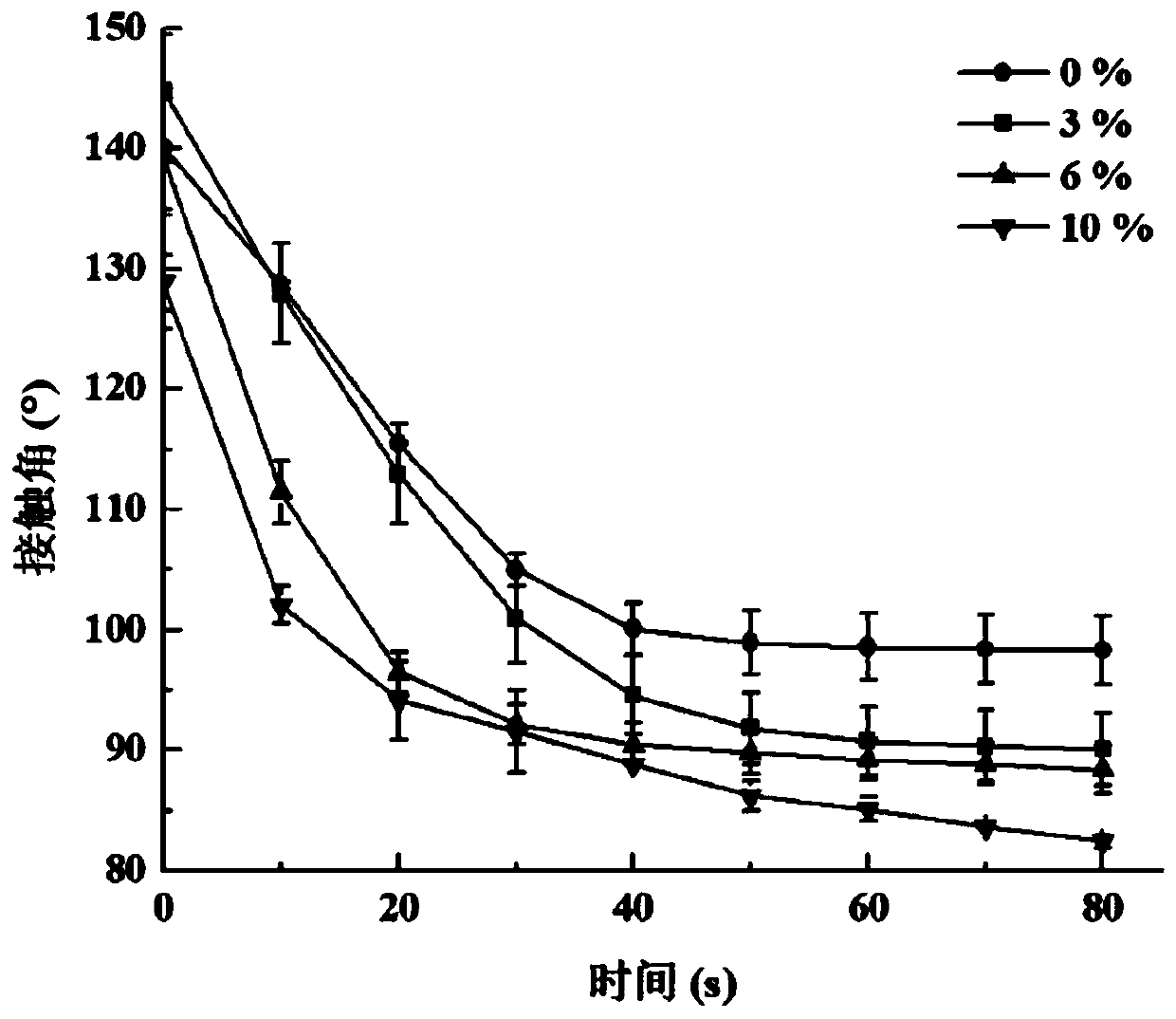

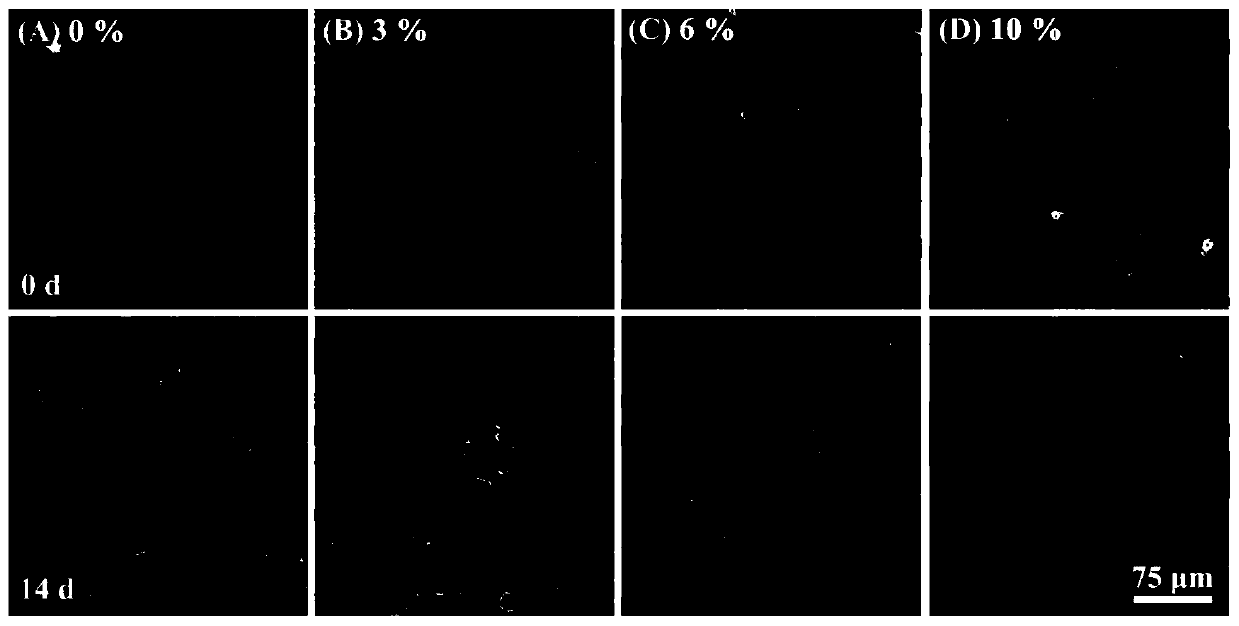

[0055] The method of Example 1 was used to prepare a high-protein nutritional bar, the only difference being that the phospholipid content was 0%, 3% and 10% respectively, and other parameters and conditions were the same as in Example 1. The texture, microstructure analysis and nutritional components of the prepared high-protein nutritional bars are shown in Tables 1-4 and Figure 1-4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com