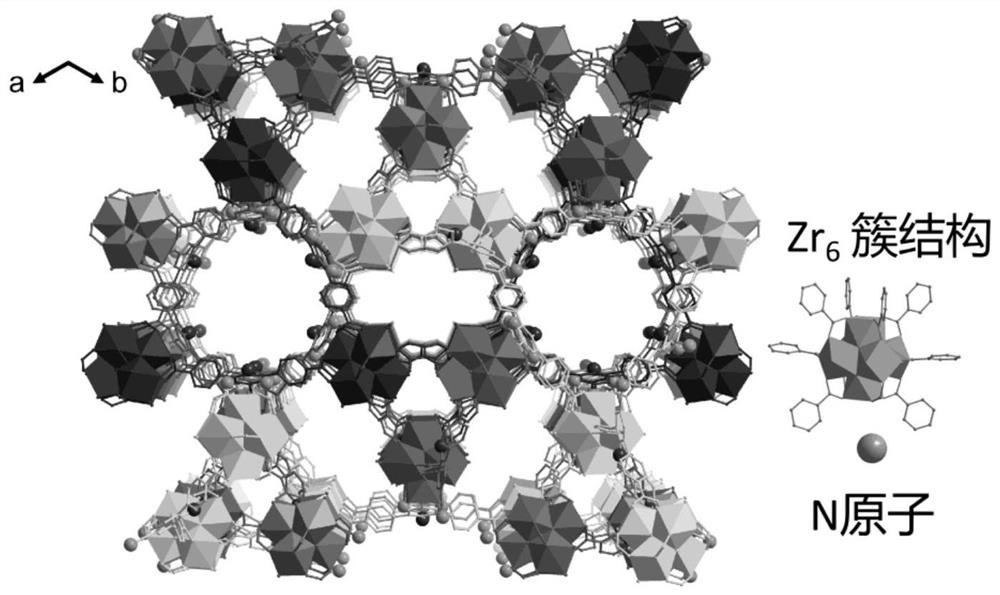

A zirconium metal-organic framework material as crystal sponge and preparation method thereof

A technology of metal-organic frameworks and crystals, applied in material analysis using radiation diffraction, analyzing materials, and using wave/particle radiation for material analysis, etc., can solve problems such as unsuitable for single crystal testing and easy loss of crystallinity, and achieve improvement The performance and preparation method are simple, and the effect of widening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

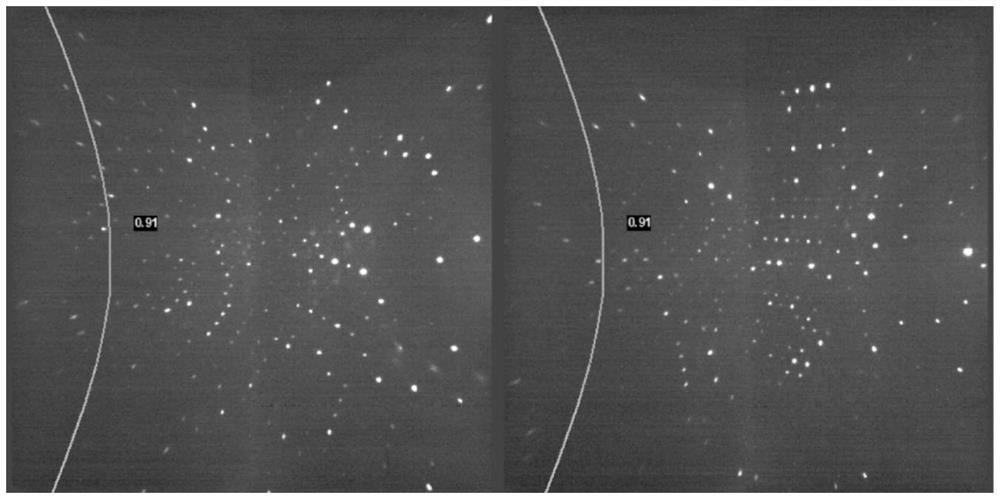

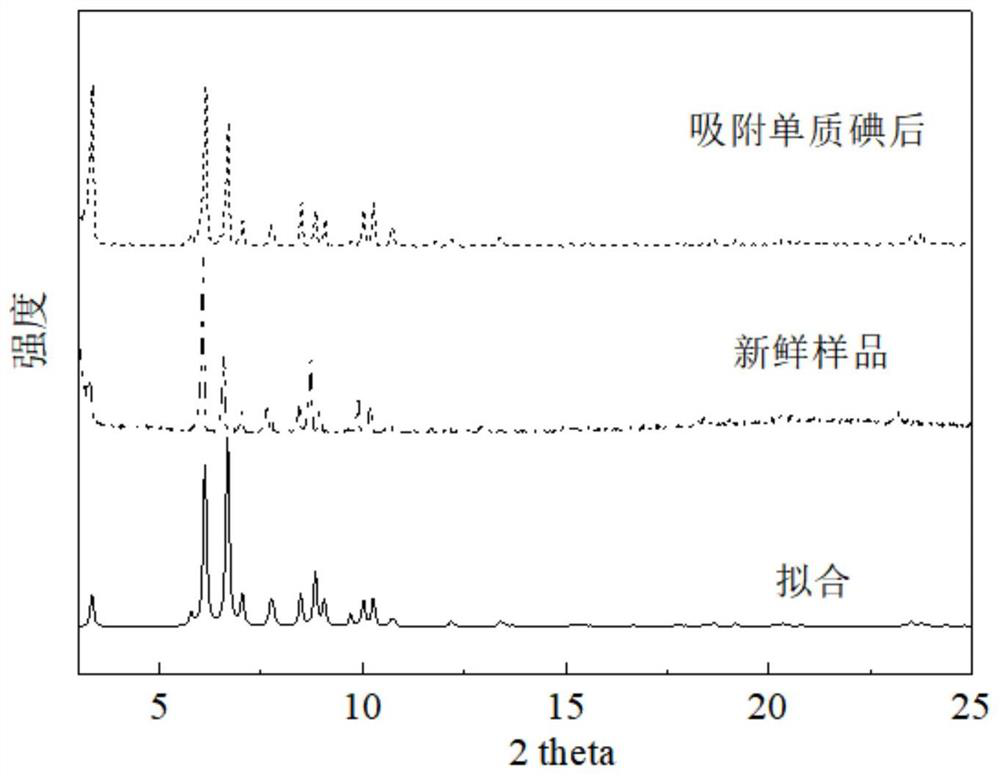

Method used

Image

Examples

Embodiment 1

[0043] Preparation of zirconium metal-organic frameworks

[0044] The preparation method is as follows:

[0045]1. Preparation of 2'-amino-5'-cyano-[1,1':3',1″-terphenyl]-4,4″-dicarboxylic acid:

[0046] (1) Under a nitrogen atmosphere, 3,5-dibromoaminobenzonitrile (16.0mmol), 4-phenylboronic acid methyl formate (38.0mmol), potassium phosphate (93.0mmol), were added to 1,4-dioxane Tetrakis(triphenylphosphine)palladium (1.1mmol) was added into the ring (500mL) solvent, then the temperature was raised to 80°C, refluxed for 45 hours, and cooled to room temperature;

[0047] (2) After removing the organic solvent by rotary evaporation, dichloromethane (100 mL) and H 2 O (50mL), the organic phase was separated, then the aqueous phase was extracted three times with dichloromethane (60mL), the combined organic phases were washed with saturated brine for extraction, and washed with anhydrous MgSO 4 Dry to obtain solution A;

[0048] (3) Solution A was rotary evaporated to remove t...

Embodiment 2

[0055] Preparation of zirconium metal-organic frameworks

[0056] The preparation method is as follows:

[0057] 1. Preparation of 2'-amino-5'-cyano-[1,1':3',1″-terphenyl]-4,4″-dicarboxylic acid:

[0058] (1) Under a nitrogen atmosphere, 3,5-dibromoaminobenzonitrile (16.8mmol), 4-phenylboronic acid methyl formate (40.0mmol), potassium phosphate (95.0mmol), were added to 1,4-dioxane Tetrakis(triphenylphosphine)palladium (1.3mmol) was added to the ring (550mL) solvent, then the temperature was raised to 100°C, refluxed for 50 hours, and cooled to room temperature;

[0059] (2) After removing the organic solvent by rotary evaporation, dichloromethane (100 mL) and H 2 O (50mL), the organic phase was separated, then the aqueous phase was extracted three times with dichloromethane (60mL), the combined organic phases were washed with saturated brine for extraction, and washed with anhydrous MgSO 4 Dry to obtain solution A;

[0060] (3) Solution A was rotary evaporated to remove t...

Embodiment 3

[0067] Preparation of zirconium metal-organic frameworks

[0068] The preparation method is as follows:

[0069] 1. Preparation of 2'-amino-5'-cyano-[1,1':3',1″-terphenyl]-4,4″-dicarboxylic acid:

[0070] (1) Under a nitrogen atmosphere, 3,5-dibromoaminobenzonitrile (16.4mmol), 4-phenylboronic acid methyl formate (39.0mmol), potassium phosphate (94.0mmol), were added to 1,4-dioxane Add tetrakis(triphenylphosphine)palladium (1.2mmol) into the ring (530mL) solvent, then raise the temperature to 90°C, reflux for 48 hours, and cool to room temperature;

[0071] (2) After removing the organic solvent by rotary evaporation, dichloromethane (100 mL) and H 2 O (50mL), the organic phase was separated, then the aqueous phase was extracted three times with dichloromethane (60mL), the combined organic phases were washed with saturated brine for extraction, and washed with anhydrous MgSO 4 Dry to obtain solution A;

[0072] (3) Solution A was rotary evaporated to remove the organic sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com