Fluorescent powder for white LED (light emitting diode) for illumination display as well as preparation method and application thereof

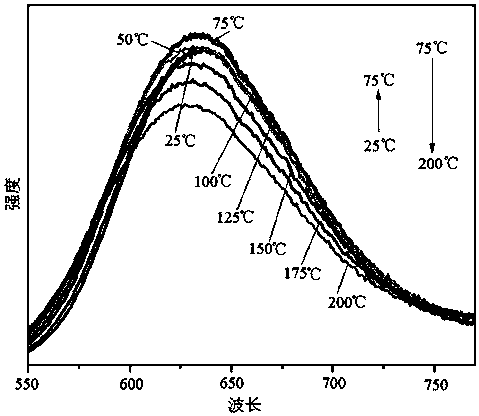

A phosphor and display technology, applied in the field of red phosphors, can solve problems such as difficulty in meeting the application requirements of high-performance devices, and achieve the effects of easy industrial production, good thermal stability, and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] According to the chemical formula (Sr 0.85 Ca 0.15 ) 1.95 Si 4.7 al 0.3 N 7.7 o 0.3 :0.05Eu 2+ The stoichiometric ratio of each raw material in Sr was weighed separately 3 N 2 , Ca 3 N 2 、Si 3 N 4 , AlN, Al 2 o 3 and EuF 3 , AlN and Al 2 o 3 The molar ratio is 1:1, then weigh the co-solvent Li 3 N and impurity-removing reagent carbon powder are mixed with the raw materials to form a mixture, and the mass fraction of the co-solvent and the impurity-removing reagent in the mixture is 1wt%. After fully grinding and mixing evenly, put it in a boron nitride crucible, put it into a high-temperature tube furnace and burn it at 1500°C for 4 hours under a nitrogen atmosphere, cool to room temperature with the furnace, grind, and sieve to make a lighting display White LEDs use red phosphors.

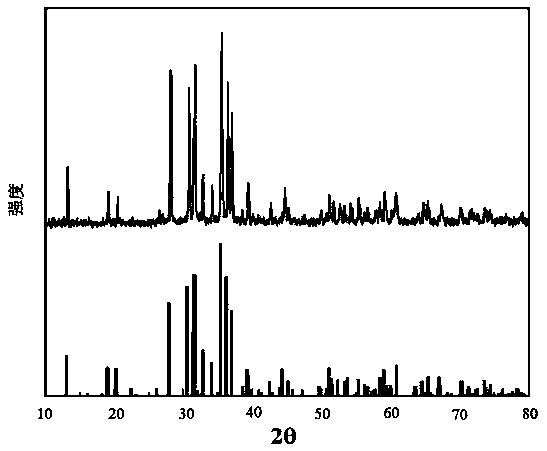

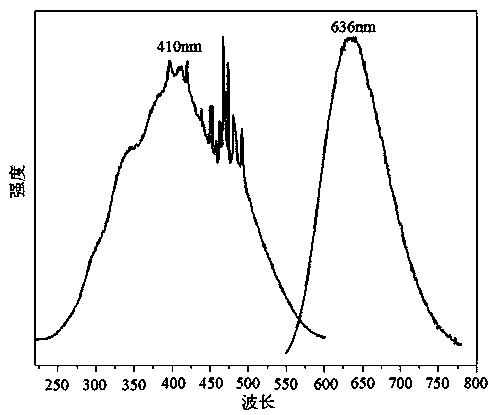

[0032] figure 1 It is the XRD collection of illustrative plates and standard collection of collections (ICSD: 401500) of the phosphor powder prepared in embodiment 1, fr...

Embodiment 2

[0042] According to the chemical formula (Sr 0.85 Ca 0.15 ) 1.95 Si 4.1 al 0.9 N 7.1 o 0.9 :0.05Eu 2+ The stoichiometric ratio of each raw material in Sr was weighed separately 3 N 2 , Ca 3 N 2 、Si 3 N 4 , AlN, Al 2 o 3 and EuF 3 , AlN and Al 2 o 3 The molar ratio is 1:1, and then weigh the co-solvent Li 3 N and impurity-removing reagent carbon powder are mixed with the raw materials taken to form a mixture. The mass fraction of the co-solvent and the impurity-removing reagent in the mixture is 1wt%; Put it into a high-temperature tube furnace and burn it at 1500° C. for 4 hours under a nitrogen atmosphere, and cool to room temperature with the furnace to obtain a red fluorescent powder for white LEDs for lighting and display.

[0043] Figure 9 Be the XRD collection of illustrative plates and the standard collection of collections (ICSD: 401500) of the phosphor powder prepared in embodiment 2, from Figure 9 It can be seen that the fluorescent powder XRD s...

Embodiment 3

[0046] According to the chemical formula (Sr 0.70 Ca 0.30 ) 1.95 Si 4.7 al 0.3 N 7.7 o 0.3 :0.05Eu 2+ The stoichiometric ratio of each raw material in Sr was weighed separately 3 N 2 , Ca 3 N 2 、Si 3 N 4 , AlN, Al 2 o 3 and EuF 3 , AlN and Al 2 o 3 The molar ratio is 1:1, and then weigh the co-solvent Li 3 N and impurity-removing reagent carbon powder are mixed with the raw materials taken to form a mixture, and the mass fraction of the co-solvent and the impurity-removing reagent in the mixture is 1wt%. After fully grinding and mixing evenly, put it in a boron nitride crucible, put it into a high-temperature tube furnace and burn it at 1500°C for 4 hours under a nitrogen atmosphere, and then cool it to room temperature to obtain a red phosphor powder for white LEDs.

[0047] Figure 11 It is the XRD collection of illustrative plates and the standard collection of collections (ICSD: 401500) of the fluorescent powder that embodiment 3 prepares, from Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com