Process for coating composite microecologiccal preparation by using solution commixing method

A composite microecology and solution blending technology, applied in the field of immobilization, can solve the problems of inconvenient transportation of bacterial liquid and short storage period, and achieve the effects of easy application and promotion, low toxicity and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

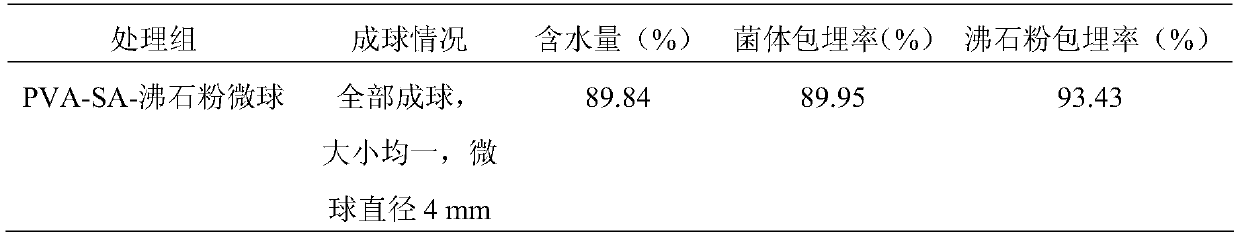

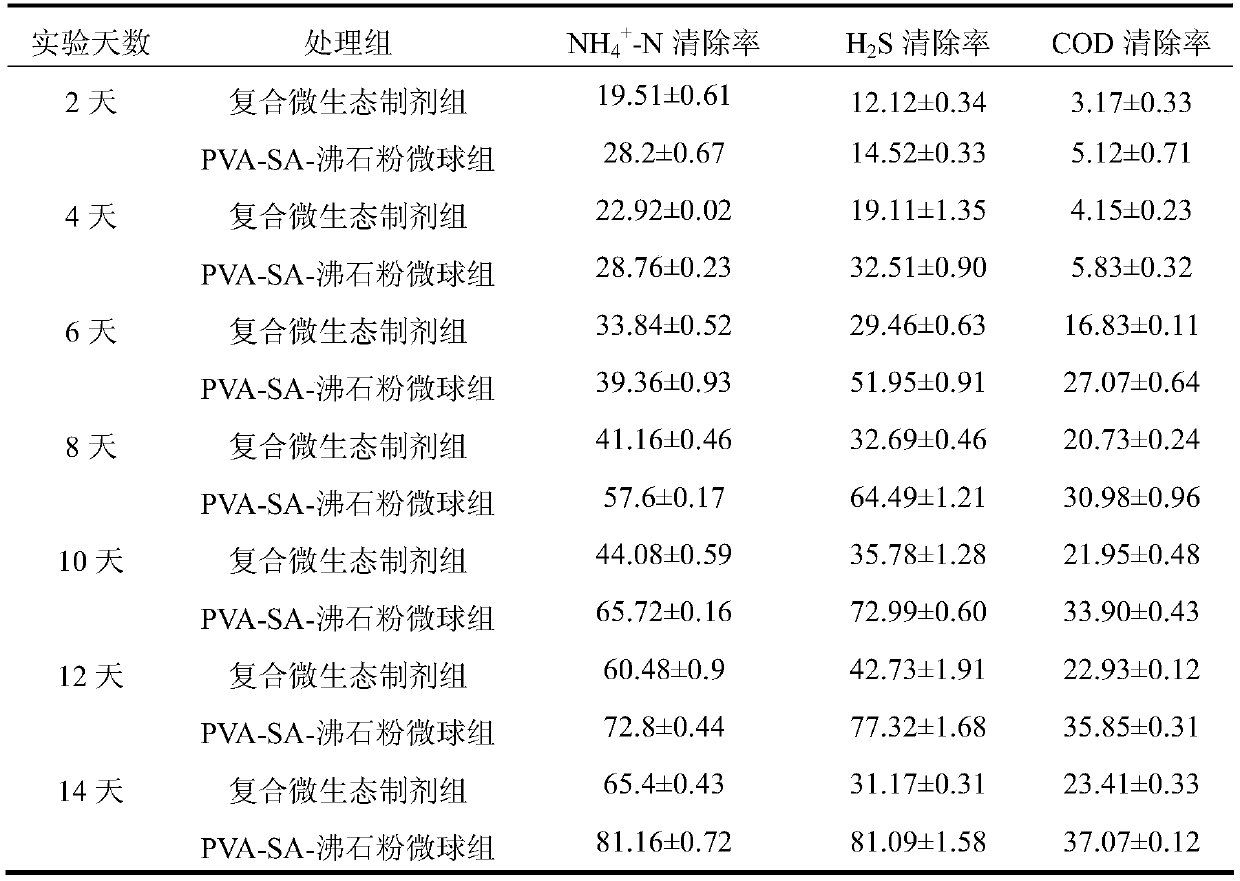

Embodiment 1

[0024] Step a. Prepare the seed solution of the composite microecological preparation: culture yeast (ACCC20165) with YPD medium at 30℃ for 24h; LB broth medium at 30℃ cultivate Bacillus (CICC20037) for 24h, LB broth medium at 30℃ cultivate photosynthetic bacteria ( CCREMSDMCC150016) 48h; Lactobacillus (ACCC11016) cultured in MRS medium at 30℃ for 48h;

[0025] The formulas of YPD medium, broth medium and MRS medium are as follows:

[0026] LB broth medium: tryptone 10g / L, yeast extract 5g / L, NaCl 10g / L, distilled water 1L, pH6.8-7.0;

[0027] YPD medium: glucose 20g / L, peptone 20g / L, yeast extract 10g / L, distilled water 1L;

[0028] MRS medium: glucose 20g / L, peptone 10g / L, beef extract 10g / L, yeast extract 5g / L, anhydrous sodium acetate 5g / L, K 2 HPO 4 2g / L, triammonium citrate 2g / L, MgSO 4 0.2g / L, MnSO 4 0.05g / L, 1L distilled water, pH 6.2-6.4;

[0029] Step b. Prepare a bacterial suspension of the composite microecological preparation: inoculate the four bacteria, Bacillus, Lact...

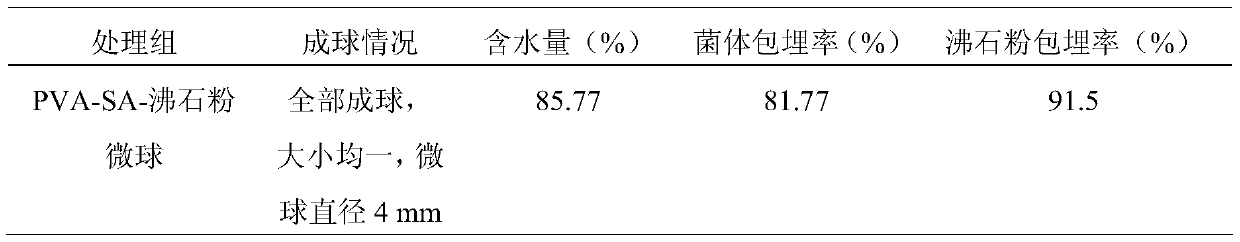

Embodiment 2

[0040] Step a. Prepare the seed solution of the composite microecological preparation: culture yeast (ACCC20165) with YPD medium at 30℃ for 24h; LB broth medium at 30℃ cultivate Bacillus (CICC20037) for 24h, LB broth medium at 30℃ cultivate photosynthetic bacteria ( CCREMSDMCC150016) 48h; Lactobacillus (ACCC11016) cultured in MRS medium at 30℃ for 48h;

[0041] The formulas of YPD medium, broth medium and MRS medium are as follows:

[0042] LB broth medium: tryptone 10g / L, yeast extract 5g / L, NaCl 10g / L, distilled water 1L, pH6.8-7.0;

[0043] YPD medium: glucose 20g / L, peptone 20g / L, yeast extract 10g / L, distilled water 1L;

[0044] MRS medium: glucose 20g / L, peptone 10g / L, beef extract 10g / L, yeast extract 5g / L, anhydrous sodium acetate 5g / L, K 2 HPO 4 2g / L, triammonium citrate 2g / L, MgSO 4 0.2g / L, MnSO 4 0.05g / L, 1L distilled water, pH 6.2-6.4;

[0045] Step b. Prepare the bacterial suspension of the composite microecological preparation: combine Bacillus CICC20037, lactic acid b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com