Injectable bioactive glass containing decalcified bone matrix DBM and preparation method and application thereof

A technology of bioactive glass and decalcified bone matrix, which is applied in the fields of pharmaceutical formulation, tissue regeneration, drug delivery, etc., can solve problems such as limited supply, need for secondary surgery, immune rejection, etc., to achieve good osteogenic performance and meet Clinical needs, the effect of improving degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An injectable bioactive glass containing demineralized bone matrix (DBM), prepared by the following method:

[0027] (1) Weigh 8 g of sodium carboxymethyl cellulose with a viscosity coefficient of 12000 mPa.s, add 100 ml of deionized water, dissolve, obtain a liquid phase, and store at room temperature for subsequent use;

[0028] (2) Mix 45S5 bioactive glass with a particle size of 10 μm and flake DBM with a size of 800 μm in a small mortar at a mass ratio of 2:1, and then accurately weigh the liquid phase at a solid-to-liquid ratio of 2:1, The liquid phase is added into the solid phase powder, and the injectable bioactive glass containing decalcified bone matrix (DBM) is obtained after being stirred rapidly and uniformly.

Embodiment 2

[0030] An injectable bioactive glass containing demineralized bone matrix (DBM), prepared by the following method:

[0031] (1) Weighing 10 g of sodium carboxymethyl cellulose with a viscosity coefficient of 8000 mPa.s, adding it to 100 ml of deionized water, dissolving to obtain a liquid phase, and storing it at room temperature for subsequent use;

[0032] (2) Mix 45S5 bioactive glass with a particle size of 4 μm and flake DBM with a size of 800 μm in a small mortar at a mass ratio of 2:1, and then accurately weigh the liquid phase at a solid-to-liquid ratio of 2:1, The liquid phase is added into the solid phase powder, and the injectable bioactive glass containing decalcified bone matrix (DBM) is obtained after being stirred rapidly and uniformly.

Embodiment 3

[0034] An injectable bioactive glass containing demineralized bone matrix (DBM), prepared by the following method:

[0035] (1) Weighing 15 g of sodium carboxymethyl cellulose with a viscosity coefficient of 10000 mPa.s, adding it to 100 ml of deionized water, dissolving to obtain a liquid phase, and storing it at room temperature for subsequent use;

[0036] (2) Mix 45S5 bioactive glass with a particle size of 40 μm and flake DBM with a size of 800 μm in a small mortar at a mass ratio of 2:1, and then accurately weigh the liquid phase at a solid-to-liquid ratio of 2:1, The liquid phase is added into the solid phase powder, and the injectable bioactive glass containing decalcified bone matrix (DBM) is obtained after being stirred rapidly and uniformly.

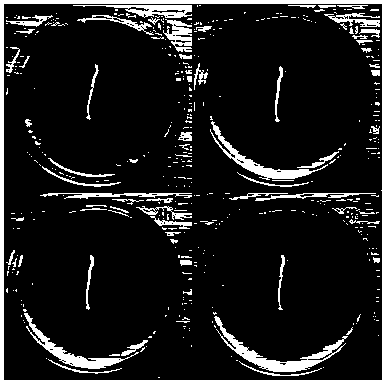

[0037] The sample of the injectable bioactive glass containing demineralized bone matrix (DBM) prepared by the present invention is carried out injection performance and anti-collapse performance test (see figure 1 ), the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com