Antenna silver paste and preparation method thereof, antenna for electronic equipment and electronic equipment

An antenna and silver paste technology, applied in antennas, conductive materials dispersed in non-conductive inorganic materials, antenna components, etc., can solve problems that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

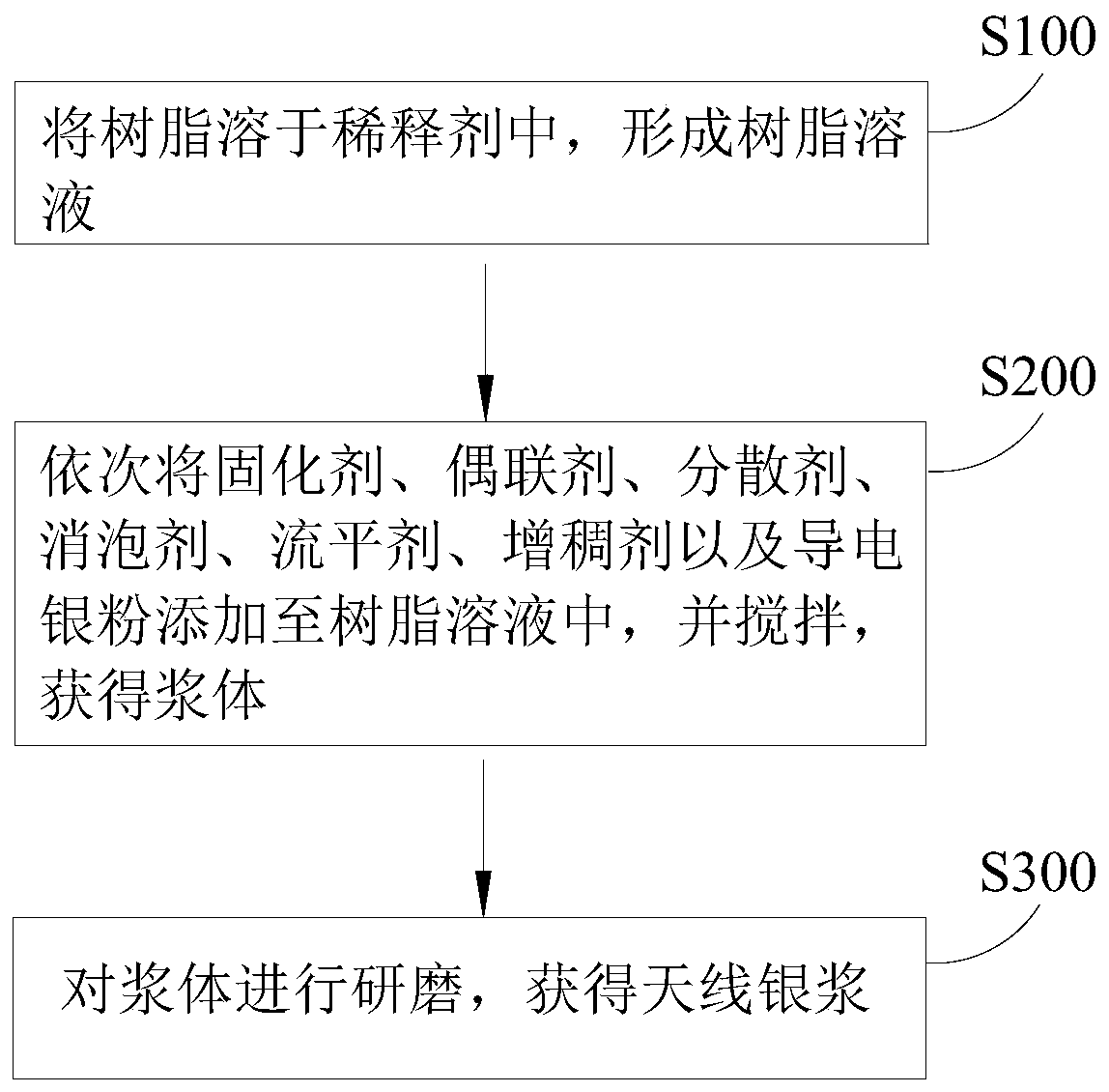

Method used

Image

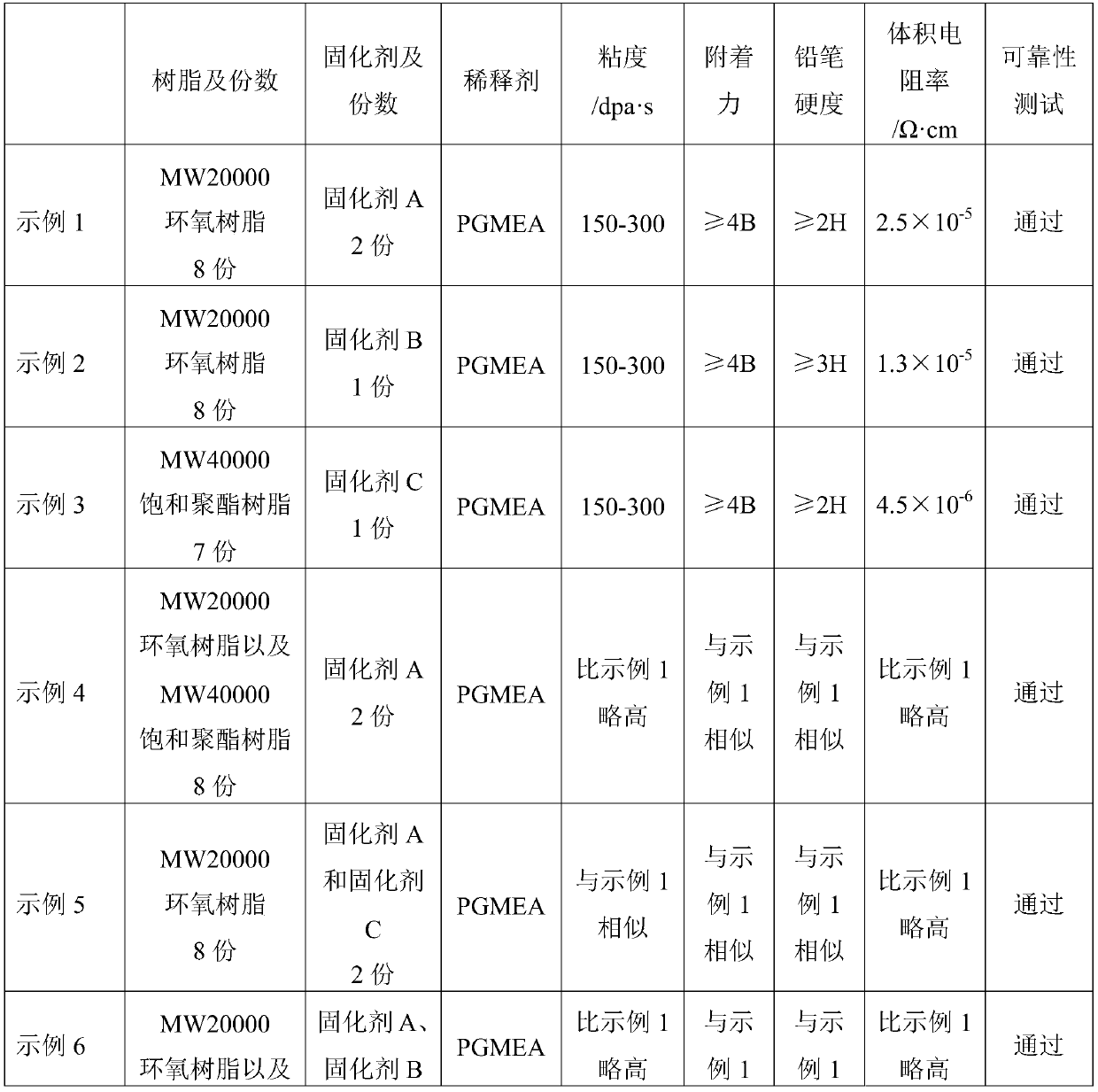

Examples

example 1

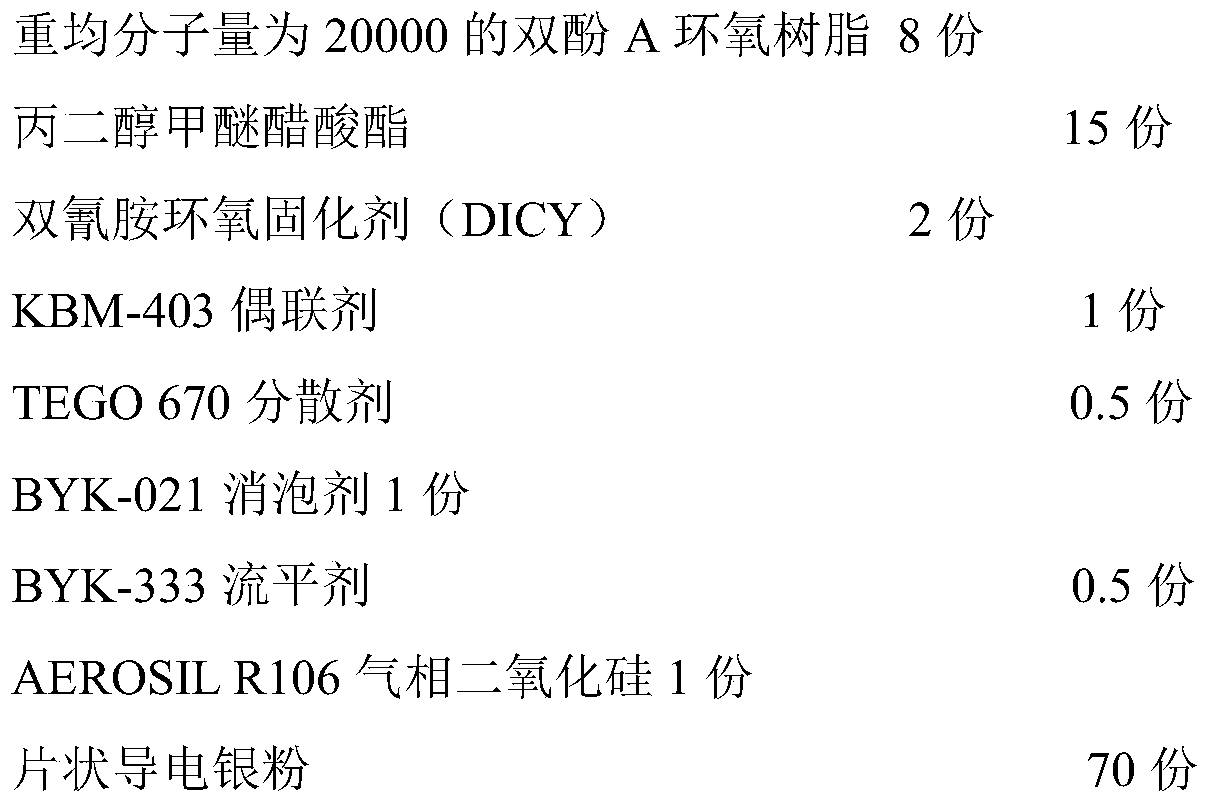

[0049] (1) The components of the antenna silver paste and the parts by weight of the corresponding components are as follows:

[0050] Weight-average molecular weight is 8 parts of bisphenol A epoxy resin of 20000

[0051] Propylene glycol methyl ether acetate 15 parts

[0052] 80 degrees imidazole latent curing agent (PN-23) 2 parts

[0053] KBM-403 coupling agent 1 part

[0054] TEGO 670 dispersant 0.5 parts

[0055] BYK-021 defoamer 1 part

[0056] BYK-333 leveling agent 0.5 parts

[0057] AEROSIL R106 fumed silica 1 part

[0058] 70 parts of flake conductive silver powder

[0059] (2) The preparation process of antenna silver paste: first dissolve the bisphenol A epoxy resin with a weight-average molecular weight of 20,000 in the propylene glycol methyl ether acetate solvent, and after the dissolution is complete, add 80-degree imidazole latent curing agent and KBM in sequence -403 coupling agent, TEGO670 dispersant, BYK-021 defoamer, BYK-333 leveling agent, AEROSIL...

example 2

[0068] (1) The components of the antenna silver paste and the parts by weight of the corresponding components are as follows:

[0069] Weight-average molecular weight is 8 parts of bisphenol A epoxy resin of 20000

[0070] Propylene glycol methyl ether acetate 15 parts

[0071] 80 degrees triaryl hexafluoroantimonate sulfonium salt cationic curing agent 1 part

[0072] KBM-403 coupling agent 1 part

[0073] TEGO 670 dispersant 0.5 parts

[0074] BYK-021 defoamer 1 part

[0075] BYK-333 leveling agent 0.5 parts

[0076] AEROSIL R106 fumed silica 1 part

[0077] 71 parts of flake conductive silver powder

[0078] (2) The preparation process of the antenna silver paste: first dissolve the bisphenol A epoxy resin with a weight-average molecular weight of 20,000 in the propylene glycol methyl ether acetate solvent, and after the dissolution is complete, add 80-degree triaryl hexafluorosulfonium antimonate salt in sequence Cationic curing agent, KBM-403 coupling agent, TEGO 6...

example 3

[0087] (1) The components of the antenna silver paste and the parts by weight of the corresponding components are as follows:

[0088] 7 parts of saturated polyester resin with a weight average molecular weight of 40000

[0089] Propylene glycol methyl ether acetate 15 parts

[0090] 80 degrees blocked isocyanate curing agent (MF-K60X) 1 part

[0091] KBM-403 coupling agent 1 part

[0092] TEGO 670 dispersant 0.5 parts

[0093] BYK-021 defoamer 1 part

[0094] BYK-333 leveling agent 0.5 parts

[0095] AEROSIL R106 fumed silica 1 part

[0096] 73 parts of flake conductive silver powder

[0097] (2) The preparation process of the antenna silver paste: first dissolve the saturated polyester resin with a weight average molecular weight of 40000 in the propylene glycol methyl ether acetate solvent. Joint agent, TEGO670 dispersant, BYK-021 defoamer, BYK-333 leveling agent, AEROSIL R106 fumed silica and flake conductive silver powder were stirred and dispersed at a speed of 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com