Preparation method of high-nickel single crystal ternary positive electrode material with core-shell structure

A technology of positive electrode material and core-shell structure, which is applied in the field of preparation of high-nickel single crystal ternary positive electrode material with core-shell structure, can solve the problems of reduced battery cycle performance and safety performance, unstable surface structure, rough surface treatment, etc., to achieve Improved safety performance and cycle performance, overcoming the effect of low efficiency and high energy density of the core-shell structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This example provides a method for preparing a high-nickel single crystal ternary cathode material with a core-shell structure, which specifically includes the following steps:

[0040] (1) Low-nickel-type nickel-cobalt-manganese hydroxide (Ni 0.5 co 0.2 mn 0.3 )OH 2 and battery-grade lithium hydroxide according to Li:Ni 0.5 co 0.2 mn 0.3 The molar ratio of =0.6:1 is dropped into dehydrated alcohol together, and the weight ratio of controlling low-nickel type nickel-cobalt-manganese hydroxide and dehydrated alcohol is 1:9, stirs evenly, is configured into a solid-liquid mixture;

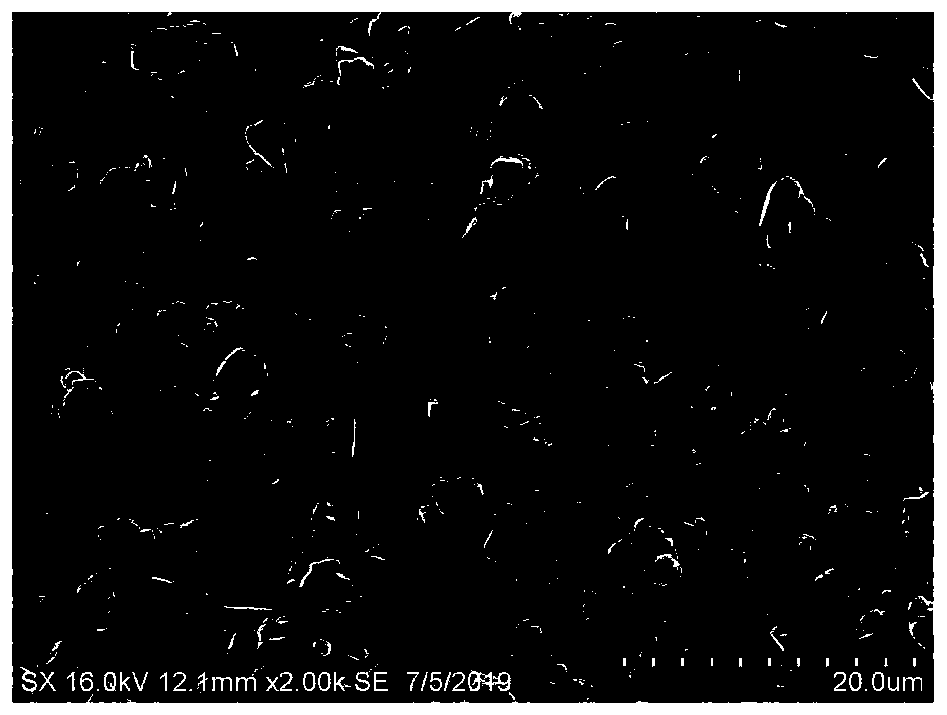

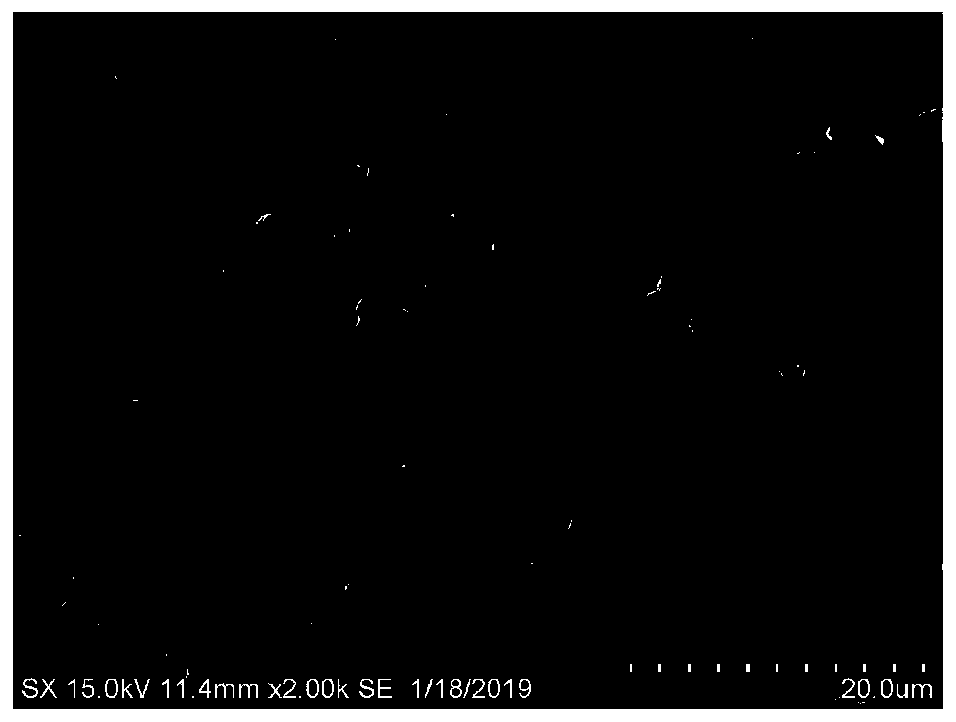

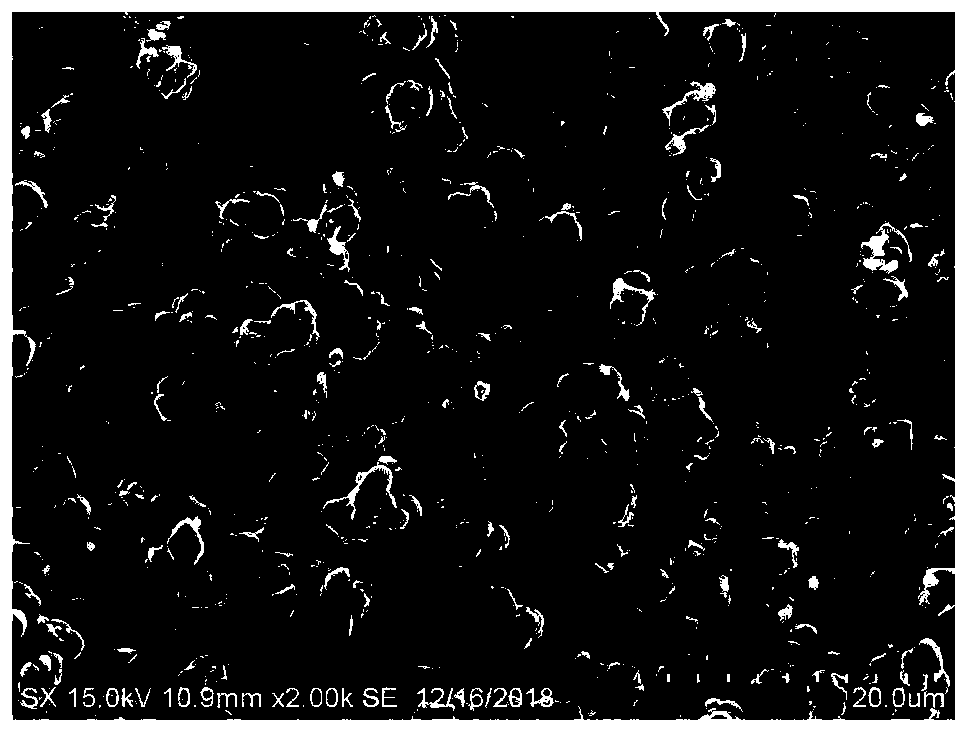

[0041] (2) In the stirred reactor, the solid-liquid mixture is continuously stirred, and then the high-nickel single crystal nickel-cobalt lithium manganese oxide ternary positive electrode material LiNi prepared in the comparative example is 0.83 co 0.11 mn 0.06 o 2 Add a stirring reactor, control the weight ratio of the solid-liquid mixture to the high-nickel single crystal nickel-c...

Embodiment 2

[0045] This example provides a method for preparing a high-nickel single crystal ternary cathode material with a core-shell structure, which specifically includes the following steps:

[0046] (1) Low-nickel-type nickel-cobalt-manganese hydroxide (Ni 0.6 co 0.2 mn 0.2 )OH 2 and battery-grade lithium hydroxide according to Li:Ni 0.6 co 0.2 mn 0.2 The molar ratio of =0.9:1 is dropped into dehydrated alcohol together, and the weight ratio of controlling low-nickel type nickel-cobalt-manganese hydroxide and dehydrated alcohol is 1:9, stirs evenly, is configured into a solid-liquid mixture;

[0047] (2) In the stirred reactor, the solid-liquid mixture is continuously stirred, and then the high-nickel single crystal nickel-cobalt lithium manganese oxide ternary positive electrode material LiNi prepared in the comparative example is 0.83 co 0.11 mn 0.06 o 2 Add a stirring reactor, control the weight ratio of the solid-liquid mixture to the high-nickel single crystal nickel-c...

Embodiment 3

[0051] This example provides a method for preparing a high-nickel single crystal ternary cathode material with a core-shell structure, which specifically includes the following steps:

[0052] (1) Cobalt tetraoxide Co with D50 around 150nm 3 o 4 Put into absolute ethanol together with battery-grade lithium hydroxide according to the molar ratio of Li:Co=0.4:1, control tricobalt tetroxide Co 3 o 4 The weight ratio with absolute ethanol is 1:9, stir evenly, configure into solid-liquid mixture;

[0053] (2) In the stirred reactor, the solid-liquid mixture is continuously stirred, and then the high-nickel single crystal nickel-cobalt lithium manganese oxide ternary positive electrode material LiNi prepared in the comparative example is 0.83 co 0.11 mn 0.06 o 2 Add a stirring reactor, control the weight ratio of the solid-liquid mixture to the high-nickel single crystal nickel-cobalt lithium manganate ternary positive electrode material to 1:2, stir the mixture at a high spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com