Enteral nutrition preparation with balanced nutrition and production device thereof

A technology for enteral nutrition preparations and production equipment, which is applied in the direction of dairy products, milk preparations, and other dairy products, can solve problems such as not being able to meet diet and nutritional needs, and improve human immunity, thicken rheology, The effect of alleviating dysphagia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

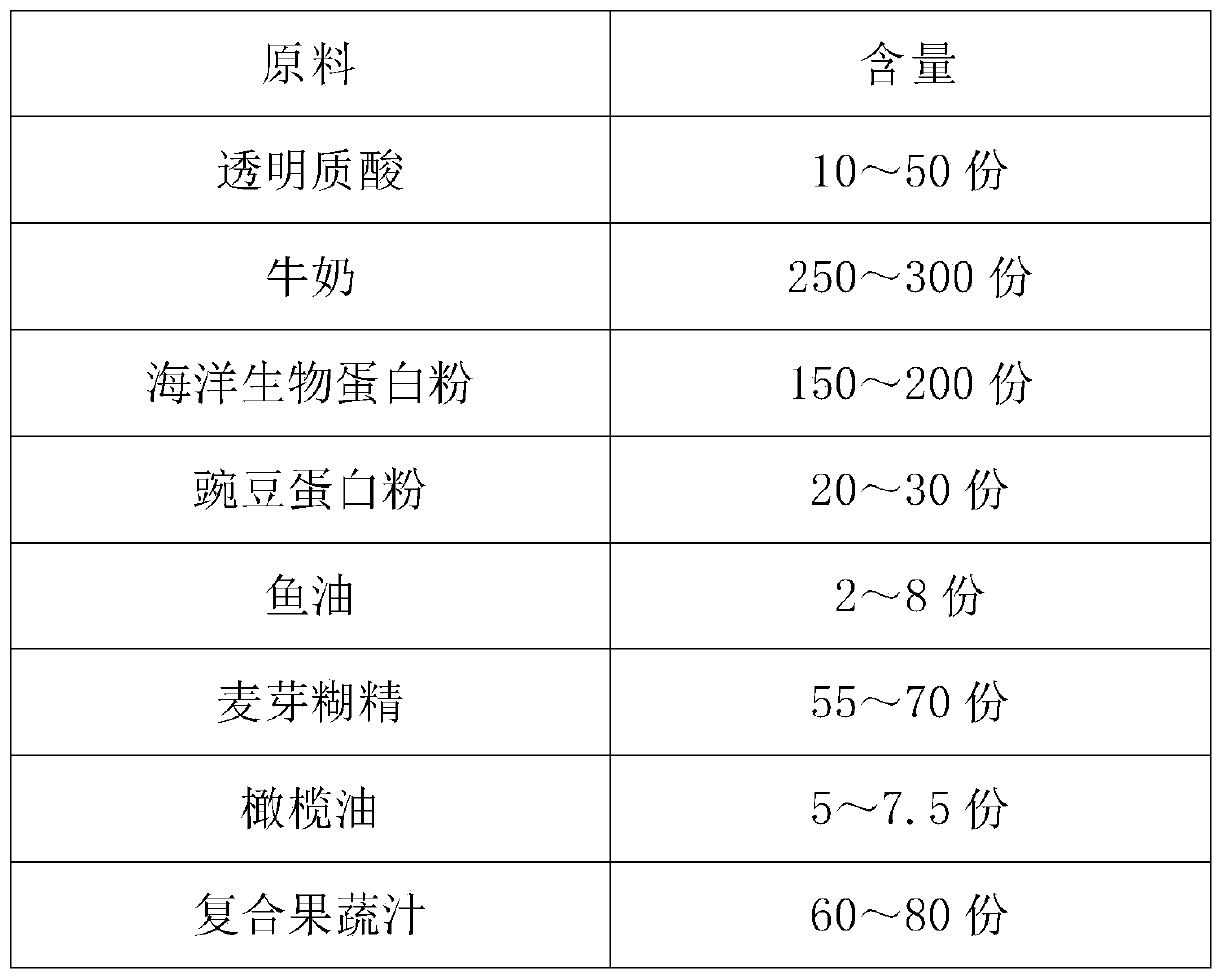

[0035] combine figure 1 , a balanced nutrition enteral nutrition preparation and its production device, including the following raw material components and contents: 10-50 parts of hyaluronic acid, 250-300 parts of milk, 150-200 parts of marine biological protein powder, 20 parts of pea protein powder ~30 parts, fish oil 2~8 parts, maltodextrin 55~70 parts, olive oil 5~7.5 parts, compound fruit and vegetable juice 60~80 parts.

[0036] The compound fruit and vegetable juice is a fruit and vegetable juice made by mixing compound fruit juice and compound vegetable juice, wherein the compound fruit juice is a fruit juice prepared from a fruit composition, wherein the fruit composition includes apples, lemons, navel oranges, pineapples, yacon, kiwi , grapes, cherries; compound vegetable juice is a vegetable juice prepared from a vegetable composition, wherein the vegetable composition includes tomato, lettuce, pumpkin, carrot, spinach, broccoli, cabbage, potato, One or a mixture ...

Embodiment 2

[0041] According to the enteral nutrition preparation of embodiment 1, its preparation comprises the steps:

[0042] S1. The configuration of the hyaluronic acid solution, take a certain amount of sodium hyaluronate powder and dissolve it in water, stir at room temperature until it is completely dissolved, and configure it as a hyaluronic acid solution of 0.1g / mol-0.5g / mol;

[0043] S2. Preparation of marine biological protein powder, take fresh marine fish meat, remove blood and wash, add 1.5 times the weight of fish meat to the fish meat, cook at high temperature and high pressure for 10-15 minutes, remove the upper layer of fat-containing solution, and then add 1.0 times the weight of the fish meat Fish weight water to get fish pulp, add protease, enzymolyze at 40-55°C, pH6-8 for 5-8h, put the enzymatic solution in a centrifuge and centrifuge at 4000-5000r / min for 15-20min , use activated carbon to remove bitterness, fishy smell, and color, then filter through a 200-mesh ny...

Embodiment 3

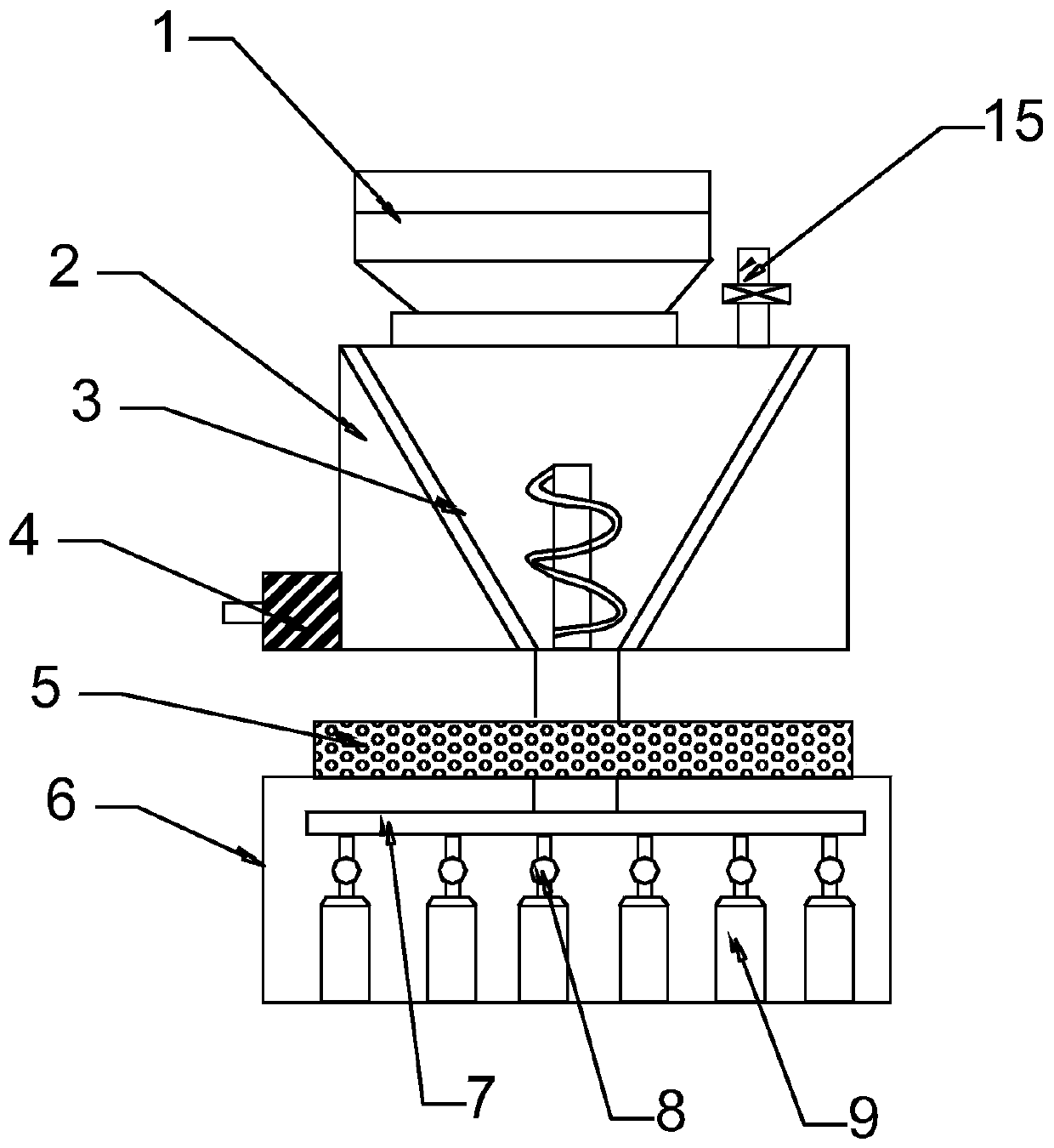

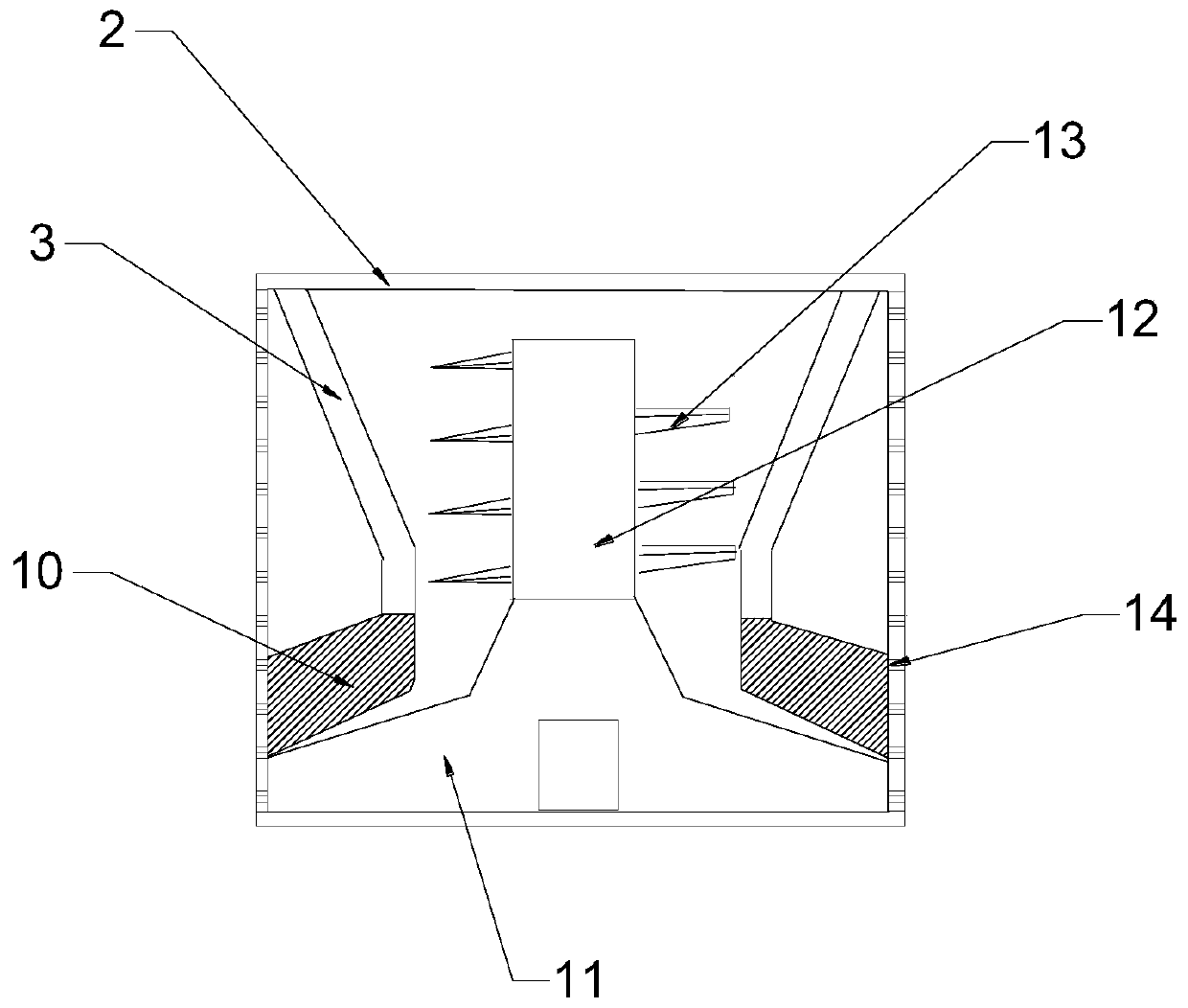

[0047] combine figure 2 and image 3 , an enteral nutrition preparation production device for producing the balanced nutrition of Example 1, comprising a feed bin 1, a grinding chamber 2, a filter chamber 5 and a collection box 6, and the upper end of the grinding chamber 2 communicates with the feed bin 1. The lower end of the grinding chamber 2 is connected to a filter chamber 5, the lower end of the filter chamber 5 is connected to the collection box 6, the outer wall side of the grinding chamber 2 is provided with a drive motor 4, and the inside of the grinding chamber 2 is provided Grinding bin 3, the bottom of the grinding bin 3 is provided with a grinding block 11, both sides of the bottom of the grinding bin 3 are provided with a fixed block 10, a gap is formed between the grinding block 11 and the fixed block 10, and the driving motor 4 The output shaft is connected with a grinding block 11, a rotating rod 12 is arranged in the middle of the grinding block 11, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com