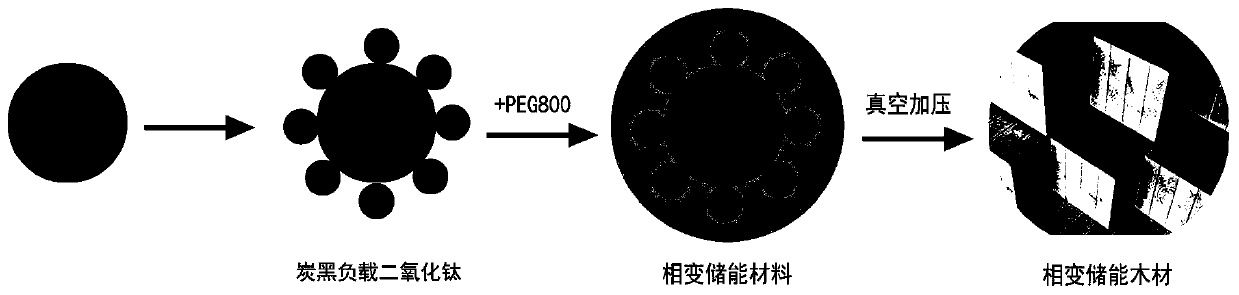

Energy-storing wood taking carbon black loaded titanium dioxide as heat-conducting filler

A titanium dioxide and thermally conductive filler technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of poor thermal stability, low thermal conductivity, easy leakage during phase change, etc., and achieve good corrosion resistance, convenient operation, and reaction. The effect of easily controlled conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An energy storage wood uses carbon black-loaded titanium dioxide as a heat-conducting filler, comprising the following steps:

[0023] (1) Select fast-growing poplar, and select mature sapwood above breast height, with specifications of length 10m×width 10mm×thickness 10mm, without defects such as cracking, decay and discoloration. After weighing, place the wood specimen in deionized water and vacuumize (-0.1MPa, 1h) to discharge the air inside the wood. Pour 500ml of deionized water into the beaker, then add 40g of sodium hydroxide and 63g of sodium sulfite, heat to 95°C and cook the wood in the mixture for 24 hours (the mixture should be replaced 3-4 times during the process). Submerge under solution. Finally, place the cooked wood in ethanol boiling liquid at 78°C for 1 hour to replace the moisture in the wood. Weigh 90ml of ethanol and 10ml of deionized water, add 3.6g of silane coupling agent KH550, drop a small amount of oxalic acid to adjust the pH value to 3, ...

Embodiment 2

[0030] An energy storage wood uses carbon black-loaded titanium dioxide as a heat-conducting filler, comprising the following steps:

[0031] (1) Select Chinese fir, and select mature sapwood above breast height, with specifications of 30mm long x 30mm wide x 20mm thick, free from defects such as cracking, decay, and discoloration. After weighing, place the wood specimen in deionized water and vacuumize (-0.1MPa, 1h) to discharge the air inside the wood. Pour 1000ml of deionized water into the beaker, then add 80g of sodium hydroxide and 126g of sodium sulfite, heat to 95°C and cook the wood in the mixture for 24 hours (the mixture should be replaced 3-4 times during the process). Submerge under solution. Finally, place the cooked wood in ethanol boiling liquid at 78°C for 1 hour to replace the moisture in the wood. Weigh 90ml of ethanol and 10ml of deionized water, add 3.6g of silane coupling agent KH550, drop a small amount of oxalic acid to adjust the pH value to 3, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com