System and method for mainstream short-cut nitrification denitrification/anaerobic ammoxidation

A technology of anaerobic ammonia oxidation and short-range nitrification, applied in the field of water pollution control, can solve the problems of high energy consumption and insufficient carbon source in sewage treatment plants, and achieve the effect of saving energy consumption of fans, better effect, and inhibiting NOB bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

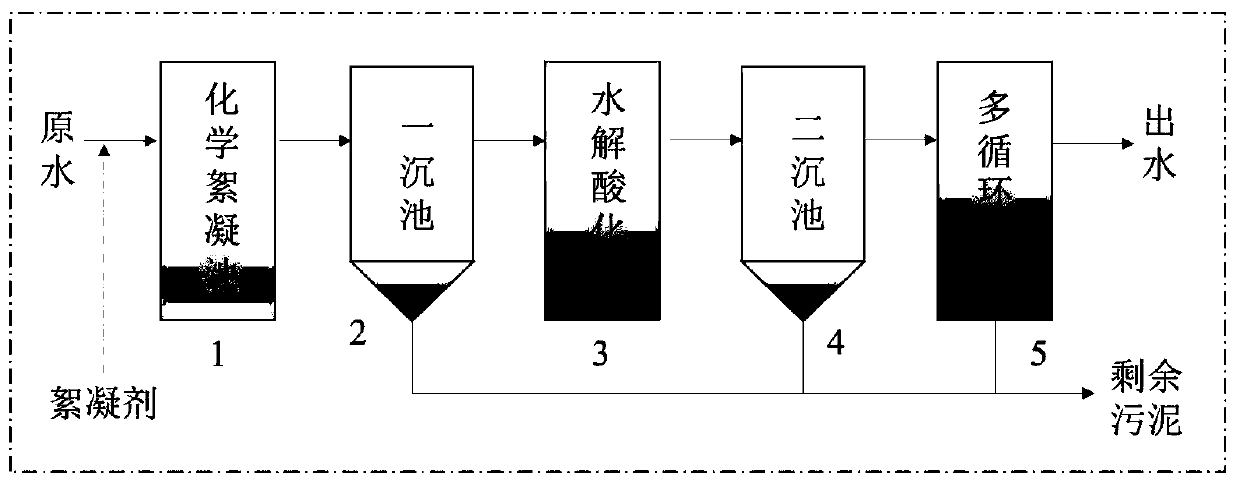

[0039] refer to figure 1 The process flow diagram of , a mainstream short-range nitrification and denitrification / anammox system, including chemical flocculation tank 1, primary sedimentation tank 2, hydrolytic acidification tank 3, secondary sedimentation tank 4, and multi-cycle SBR tank 5 connected in sequence; The chemical flocculation tank 1 is provided with a water inlet, and the flocculant can be added to the water inlet pipe, or directly added to the chemical flocculation tank 1, and mixed by stirring; the multi-circulation SBR tank 5 is provided with a water outlet; the first settling tank 2, the bottom of the secondary sedimentation tank 4 and the bottom of the multi-circulation SBR pool 5 are respectively provided with a sludge collection pipeline, and the sludge collection pipeline outlet at the bottom of the primary sedimentation tank 2, the secondary sedimentation tank 4 and the bottom of the multi-circulation SBR pool 5 is connected to The same pipeline is discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com