Method for preparing PVA (Polyvinyl Alcohol) fiber and steel fiber reinforced concrete

A technology for reinforcing concrete and steel fibers, applied in cement production, etc., can solve the problems of high brittleness and low crack resistance, and achieve the effects of high tensile strength, good dispersion and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1PVA fiber and steel fiber reinforced concrete raw material

[0028] The raw materials used to prepare PVA fiber and steel fiber reinforced concrete in the present invention mainly include metakaolin, fly ash, sand, gravel, alkali activator, PVA fiber, steel fiber, water reducer, and the performance index of the raw material used meets the test requirements ,details as follows:

[0029] (1) fly ash

[0030] The fly ash that adopts in the present invention is the I grade fly ash that Luoyang Power Plant produces, and its main component and physical properties are shown in Table 1 and Table 2:

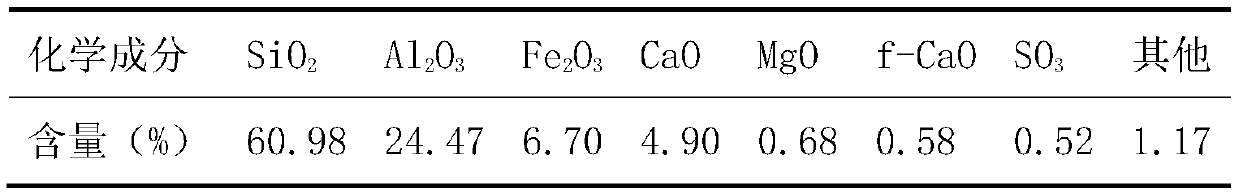

[0031] Table 1 Main chemical components of Class I fly ash

[0032]

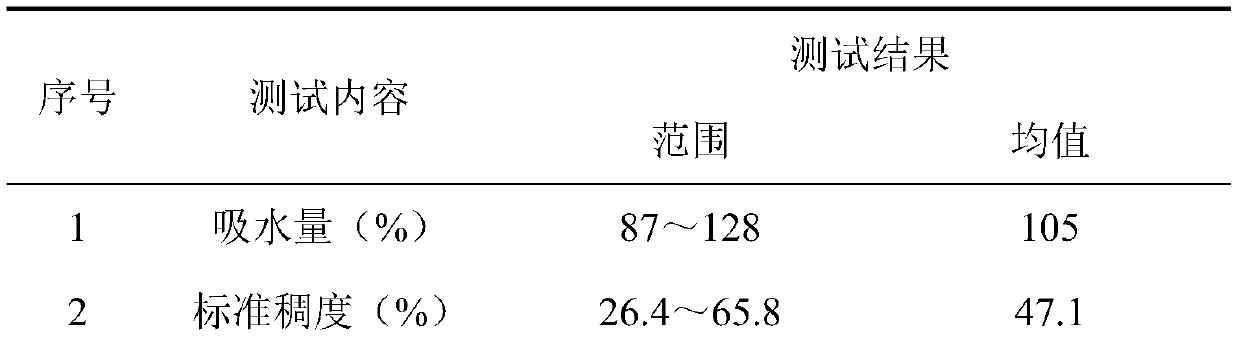

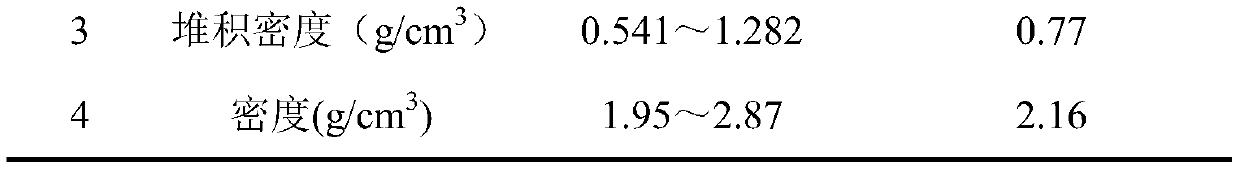

[0033] Table 2 Main physical properties of Class I fly ash

[0034]

[0035]

[0036] (2) Metakaolin

[0037] The metakaolin used in the present invention is the high-quality metakaolin produced by Shijiazhuang Chenxing Industrial Co., Ltd., which has better activity and is easily activat...

Embodiment 2

[0069] Embodiment 2 PVA fiber and steel fiber reinforced concrete mix ratio design

[0070] The present invention mainly studies the influence of different dosages of PVA fibers and steel fibers on the basic mechanical properties and fracture properties of fiber-reinforced GPC. Therefore, in the process of designing the mix ratio, the different dosages of the two fibers are mainly considered, and the control variables are used in the test. The method is to fix the water-binder ratio, bone-bone ratio, sand rate, water glass modulus and alkali content and change the amount of PVA fiber or steel fiber alone.

[0071] Since GPC is still in the stage of research and development, there is no complete and unified mix ratio design procedure, so when designing the mix ratio of the benchmark GPC, it is mainly referred to the "Ordinary Concrete Mix Ratio Design Regulations" (JGJ55-2011) and domestic and foreign scholars' research on ground The research progress of polymer concrete mix ra...

Embodiment 3

[0076] The preparation technology of embodiment 3PVA fiber and steel fiber reinforced concrete

[0077] In the process of mixing fiber-reinforced geopolymer concrete, in order to ensure that the fibers can be evenly distributed and freely dispersed in the matrix, the different properties of the two fibers should be considered. Among them, PVA fiber is light in weight, short in length, and easy to absorb. Therefore, firstly, stir the PVA fiber and the cementitious material for 2 minutes. After mixing evenly, add the aggregate and stir for another 2 minutes. Finally, add the prepared alkali activator and high-efficiency water reducer to continue stirring. 2min; and the steel fiber has a large weight, firm quality, and a large amount of mixing, so the steel fiber, cementitious material and aggregate can be mixed and stirred for 2 minutes, and then the activator and water reducer are added and stirred for 2 minutes. When preparing the alkali activator, add flake NaOH into the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com