Application method of epoxy modified polyester resin in synthesis of precoated metal coil coating primer

An epoxy-modified polyester and metal coil technology, applied in polyester coatings, anti-corrosion coatings, coatings, etc., can solve the problems of obvious storage stratification, batch dosage fluctuations, and T-bending performance decline. The effect of increasing flexibility, increasing crosslink density, increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

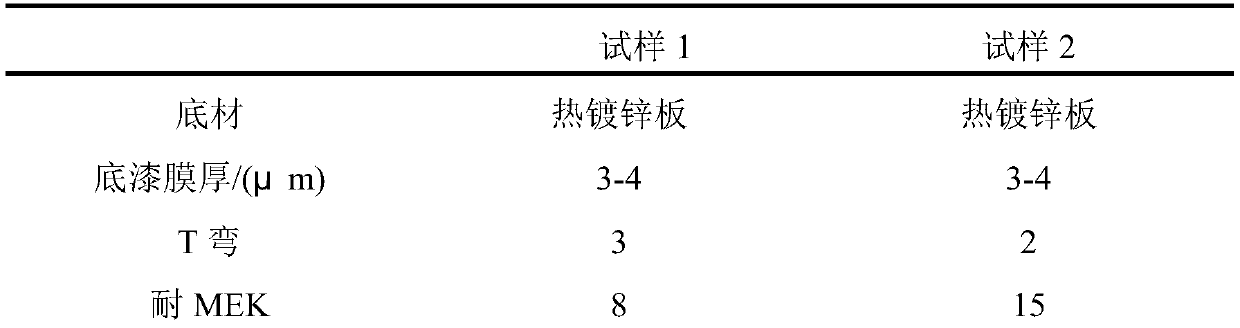

[0014] In the invention, the epoxy modified polyester resin is synthesized first, and then compared with the performance difference of the polyester resin added with epoxy resin in the pre-coated metal coil coating primer.

[0015] (1) Synthesis of epoxy modified polyester resin

[0016] Main raw materials and equipment

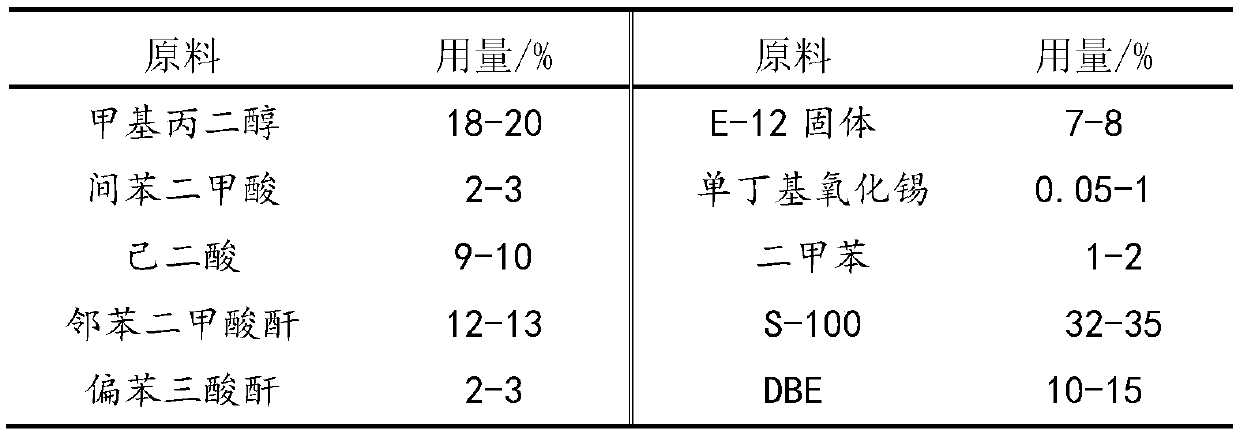

[0017] Methyl propylene glycol, isophthalic acid, adipic acid, phthalic anhydride, trimellitic acid, E-12 resin, monobutyl tin oxide, xylene, S-100 (mixed aromatic solvent S-100) , DBE (mixed dimethyl dibasic acid).

[0018] KDM type adjustable thermoelectric heating mantle, precision booster electric stirrer, refrigerator.

[0019] Raw material ratio (see Table 1)

[0020] Table 1 Raw material ratio

[0021]

[0022] Synthesis

[0023] (1) Put the first 7 items into a three-necked flask with a thermometer, agitator and a condenser, slowly heat up until the material melts, and start stirring.

[0024] (2) Control the temperature of the material at 150-160℃ for heat preser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com