Carbon nanofiber composite material loaded with nickel hydroxide nanosheets and nickel cobaltate nanocrystals, and preparation method thereof and application of carbon nanofiber composite material loaded with nickel hydroxide nanosheets and nickel cobaltate nanocrystals

A carbon nanofiber, nickel hydroxide technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of structural instability, poor conductivity, etc. Discharge rate, tight bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

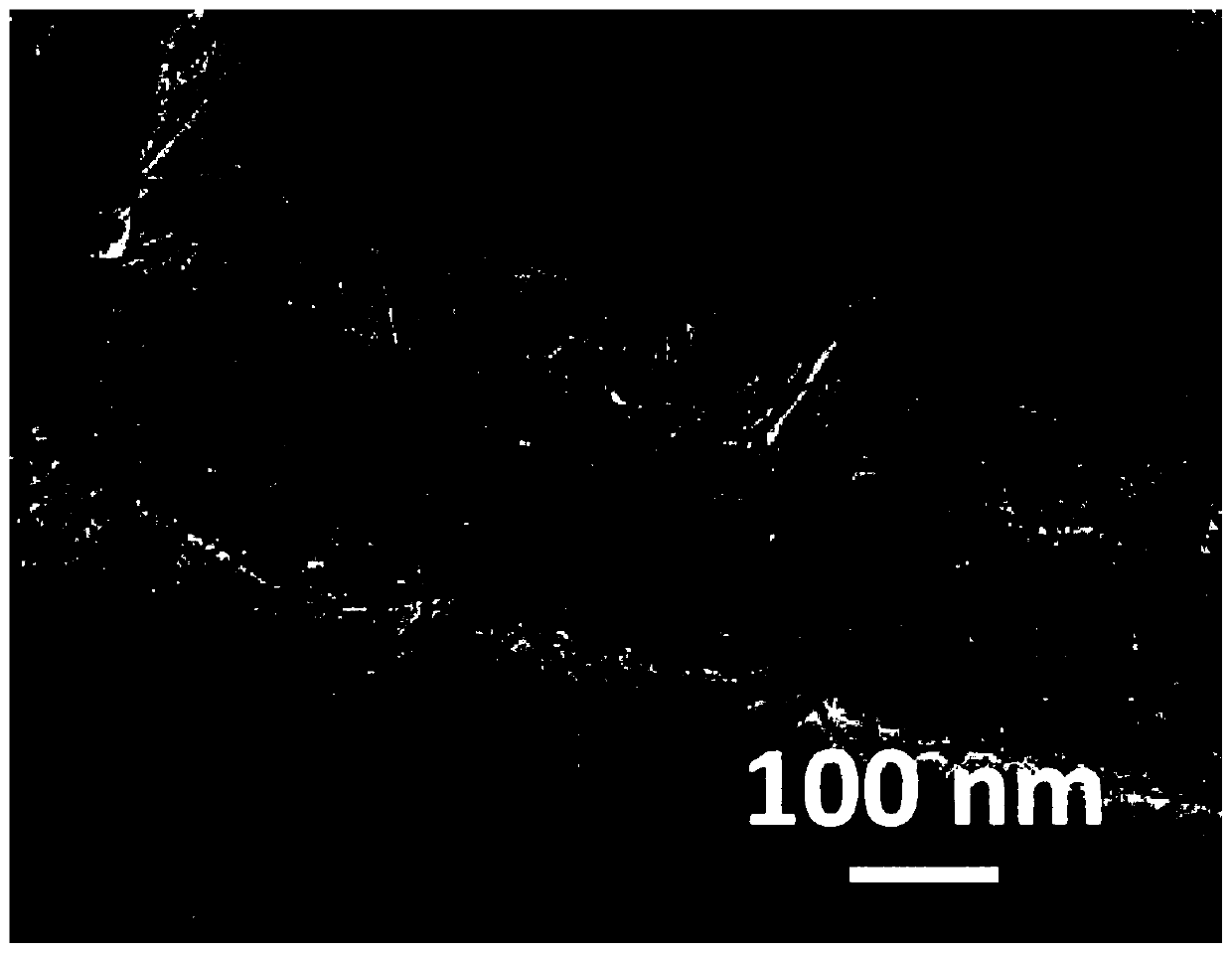

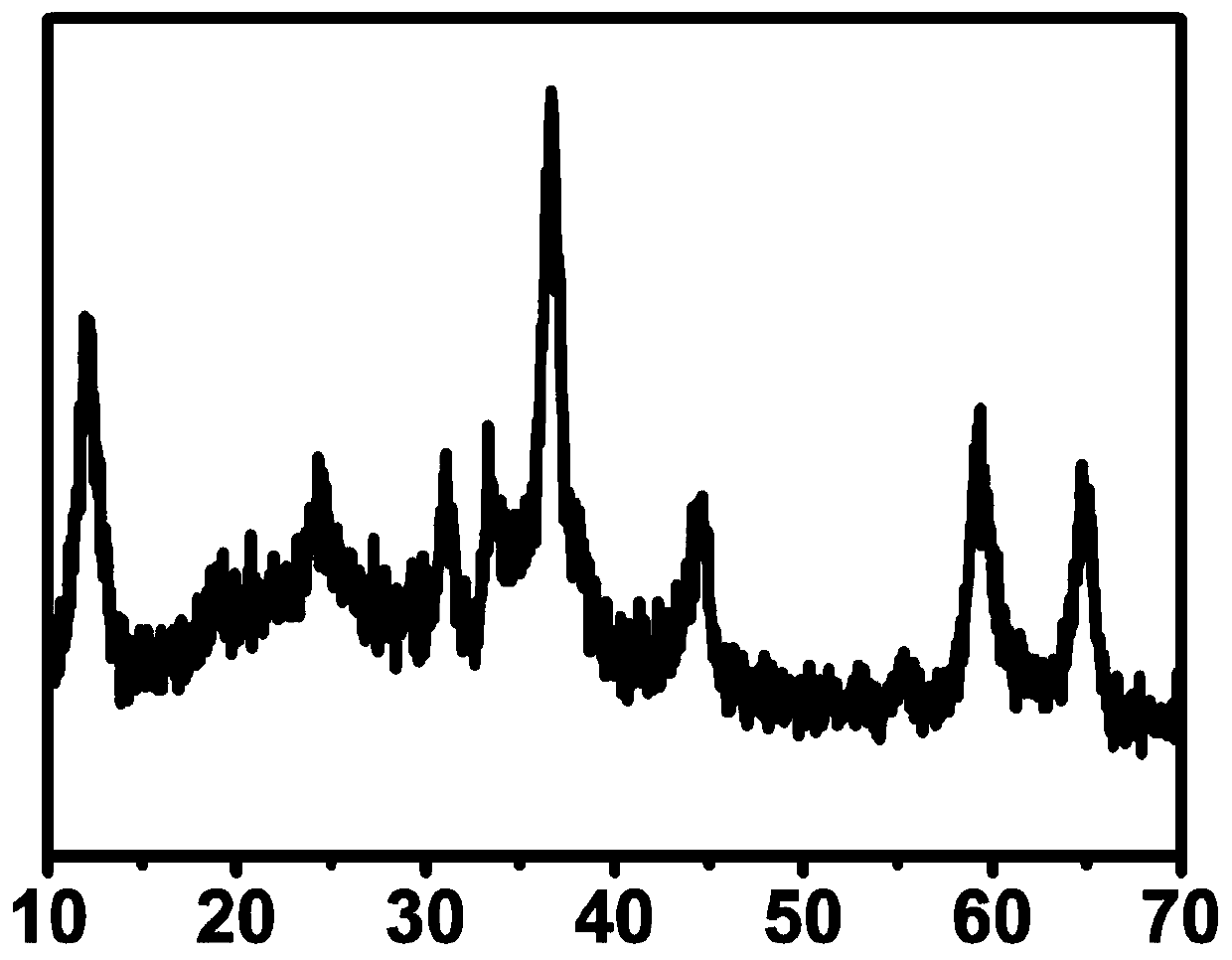

[0042] Preparation of carbon nanofiber composites (NCH CNF) loaded with nickel hydroxide nanosheets and nickel cobaltate nanocrystals:

[0043] (1) Dissolve 0.3g of polyacrylonitrile (PAN) in 10mL of N,N-dimethylformamide organic solution, heat at 80°C and stir for 30 minutes until completely dissolved, then add 0.3g of polyvinylpyrrolidone (PVP) respectively , 0.5g cobalt acetate, 0.25g nickel acetate, and continuously stirred for 24 hours to form a uniform transparent organic liquid to prepare a precursor solution. Keep the air humidity at 15%, electrospin at 15kV and 30°C, keep 2mL h -1 Spinning at a dripping rate of 4 hours, standing and drying at 80°C overnight to obtain a carbon nanofiber precursor;

[0044] (2) Put the prepared electrospun nanofibers into a quartz tube, and heat them at 1°C min under a nitrogen atmosphere. -1 Calcined at a heating rate of 500°C, kept for 300 minutes when the temperature reached 500°C, and then cooled naturally to obtain a carbon nanof...

Embodiment 2

[0049] Preparation of NCH-CNF:

[0050] (1) Dissolve 0.25g of polyacrylonitrile (PAN) in 10mL of N,N-dimethylformamide organic solution, heat at 80°C and stir for 30 minutes until completely dissolved, then add 0.25g of polyvinylpyrrolidone (PVP) respectively , 0.25g cobalt acetate, 0.5g nickel acetate, and continuously stirred for 24 hours to form a uniform transparent organic liquid to prepare a precursor solution. Keep the air humidity at 15%, electrospin at 15kV and 30°C, keep 2mL h -1 Spinning at a dripping rate of 4 hours, standing and drying at 80°C overnight to obtain a carbon nanofiber precursor;

[0051] (2) Put the prepared electrospun nanofibers into a quartz tube, and heat them at 3°C min under a nitrogen atmosphere. -1 Calcined at a heating rate of 400°C, kept for 240 minutes when the temperature reached 400°C, and then cooled naturally to obtain a carbon nanofiber composite material loaded with nickel cobaltate nanocrystals;

[0052] (3) Disperse 0.02g of c...

Embodiment 3

[0055] Preparation of NCH-CNF:

[0056] (1) Dissolve 0.2g of polyacrylonitrile (PAN) in 10mL of N,N-dimethylformamide organic solution, heat at 80°C and stir for 30 minutes until completely dissolved, then add 0.2g of polyvinylpyrrolidone (PVP) respectively , 0.5g cobalt acetate, 0.25g nickel acetate, and continuously stirred for 24 hours to form a uniform transparent organic liquid to prepare a precursor solution. Keep the air humidity at 15%, electrospin at 15kV and 30°C, keep 2mL h -1 Spinning at a dripping rate of 4 hours, standing and drying at 80°C overnight to obtain a carbon nanofiber precursor;

[0057] (2) Put the prepared electrospun nanofibers into a quartz tube, and heat them at 5°C min under a nitrogen atmosphere. -1 Calcined at a heating rate of 600°C, kept for 120 minutes when the temperature reached 600°C, and then cooled naturally to obtain a carbon nanofiber composite material loaded with nickel cobaltate nanocrystals;

[0058] (3) Disperse 0.02g of carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com