Device and method for cooperatively treating pickling waste liquid and electroplating sludge by using electrodialysis technology

A technology of electroplating sludge and pickling waste liquid, which is applied in the field of electrochemistry, can solve the problems of low treatment efficiency, waste of resources and energy, and low efficiency of heavy metal removal or utilization, and achieve the effect of reducing energy input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1. Device installation;

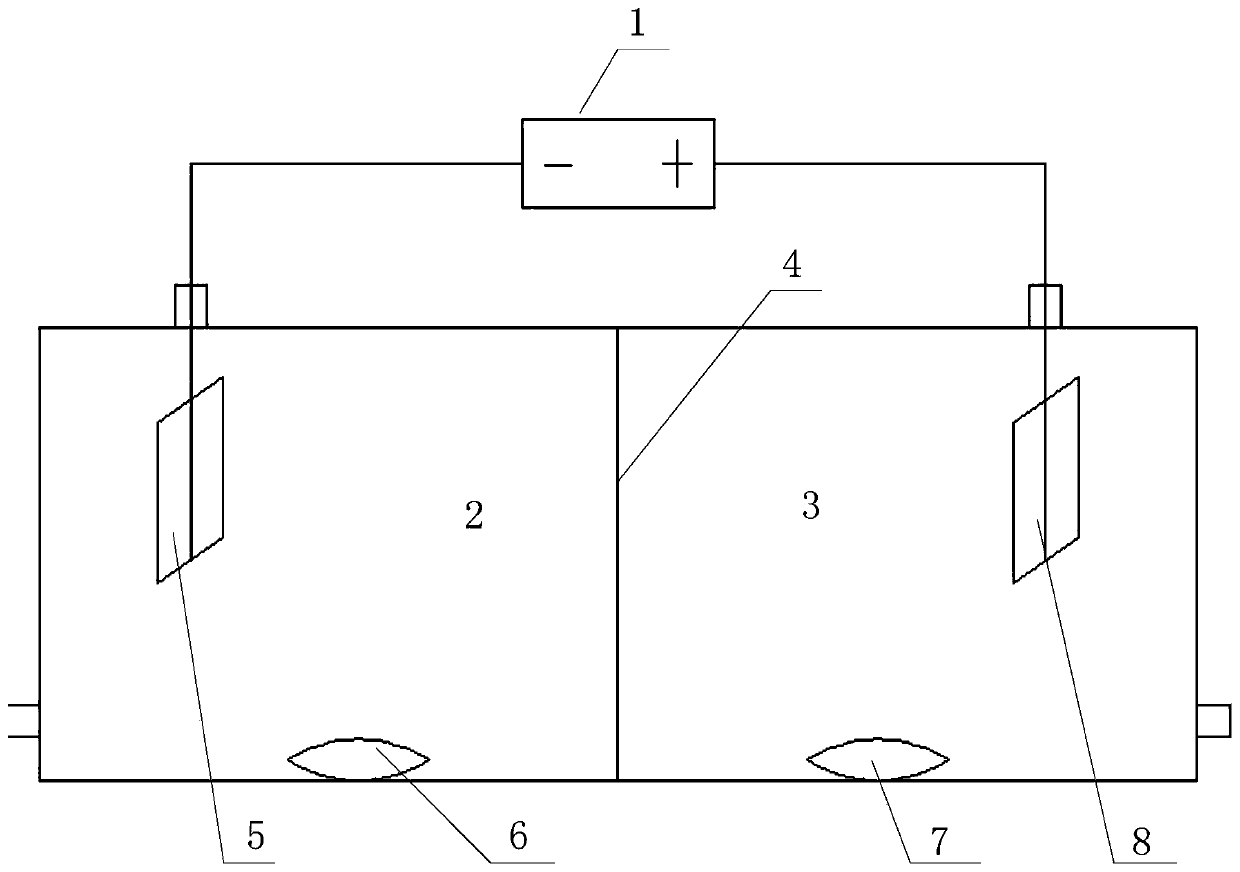

[0038] The electrodialysis device is assembled according to the schematic diagram of the device. After the assembly is completed, the treated pickling waste liquid is added to the anode area, and the treated mud-water mixture with a mud-to-water volume ratio of 1:9 is added to the cathode area. Electrodes are installed and titanium wires are used. Connection, the external circuit is connected to a DC power supply.

[0039] Step 2. The device operates at 0.5V;

[0040] Start the electrodialysis device according to step 1. Under the action of direct current, the hydrogen ions in the pickling waste liquid in the anode area enter the cathode area through the proton exchange membrane, and react with the electroplating sludge to promote the dissolution of heavy metals in the electroplating sludge. The pH value of the waste washing liquid increased from 0.12 to 1.3.

[0041] Step 3. Metal Removal and Recovery

[0042] After the device runs for...

Embodiment 2

[0044] Step 1. Device installation;

[0045] According to the schematic diagram of the device, the electrodialysis device is assembled. After the assembly is completed, the treated pickling waste liquid is added to the anode area, and the treated mud-water mixture (ie, electroplating sludge and water) with a mud-water volume ratio of 1:9 is added to the cathode area. Electrodes are installed and connected with titanium wires, and the external circuit is connected with a DC power supply.

[0046] Step 2. The device operates at 1.2V;

[0047] Start the electrodialysis device according to step 1. Under the action of direct current, the hydrogen ions in the pickling waste liquid in the anode area enter the cathode area through the proton exchange membrane, and react with the electroplating sludge to promote the dissolution of heavy metals in the electroplating sludge. The pH value of the waste washing liquid increased from 0.12 to 1.54.

[0048] Step 3. Metal Removal and Recover...

Embodiment 3

[0051] Step 1. Device installation;

[0052] According to the schematic diagram of the device, the electrodialysis device is assembled. After the assembly is completed, the treated pickling waste liquid is added to the anode area, and the treated mud-water mixture (ie, electroplating sludge and water) with a mud-water volume ratio of 1:9 is added to the cathode area. Electrodes are installed and connected with titanium wires, and the external circuit is connected with a DC power supply.

[0053] Step 2. The device operates under 2.1V;

[0054] Start the electrodialysis device according to step 1. Under the action of direct current, the hydrogen ions in the pickling waste liquid in the anode area enter the cathode area through the proton exchange membrane, and react with the electroplating sludge to promote the dissolution of heavy metals in the electroplating sludge. The pH value of the waste washing liquid increased from 0.12 to 1.91.

[0055] Step 3. Metal removal and reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com