Method for treating waste water by photodecomposition cooperative electrical reaction

A technology for wastewater treatment and photolysis, applied in chemical instruments and methods, light water/sewage treatment, water/sewage treatment, etc., can solve the problems of large amount of solid waste, low reuse rate, pollution, etc. and total nitrogen, reducing the amount of solid waste, and reducing the amount of solid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

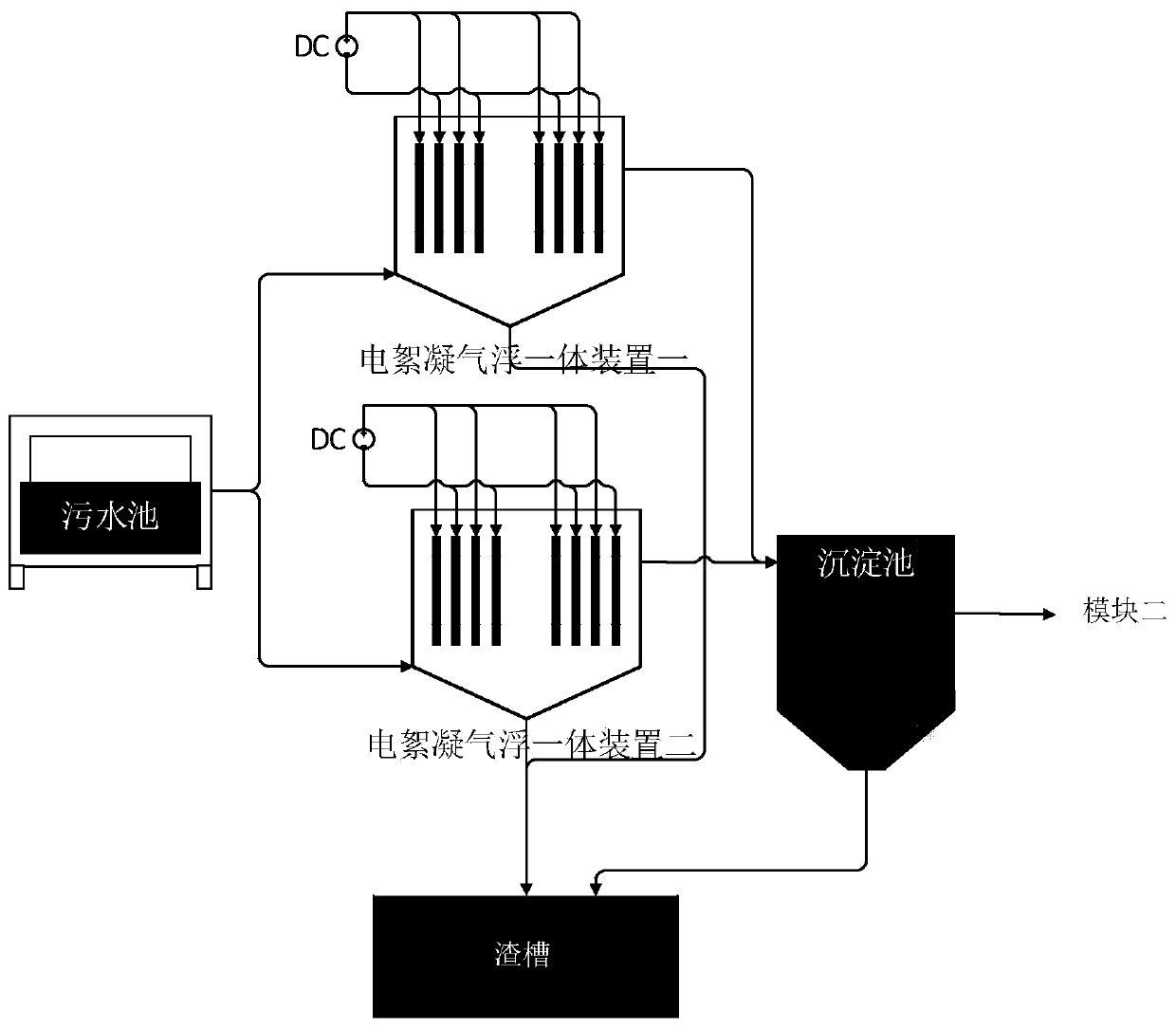

[0078] Such as Figure 1-2 Shown is a method for treating waste water through photolysis and electrical reaction, and the process comprises the steps of:

[0079] Step S1: electrocoagulation air flotation sedimentation treatment of printing and dyeing wastewater;

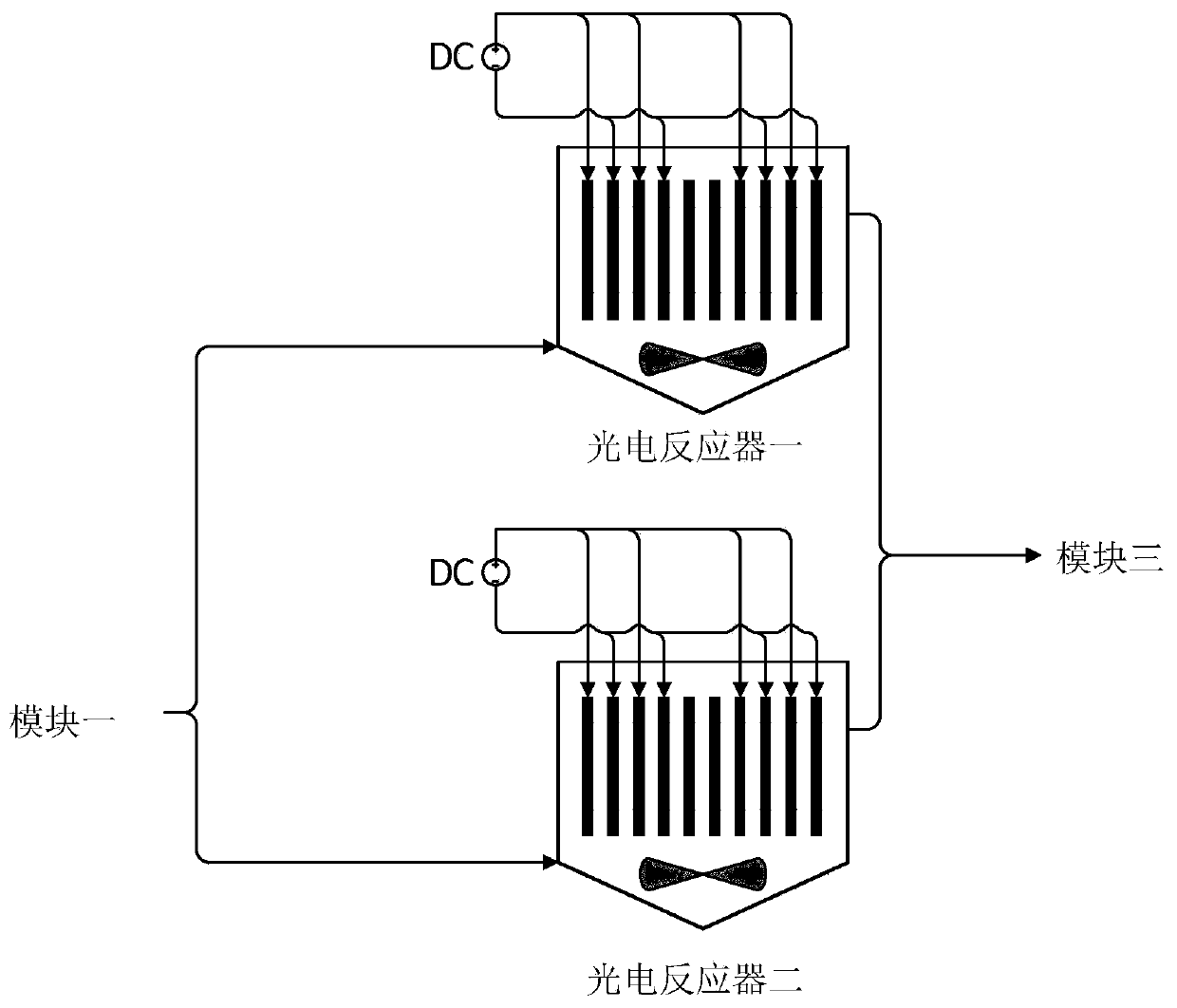

[0080] Step S2: the printing and dyeing wastewater treated in step S1 is treated by photolysis and electrochemical reaction;

[0081] Step S3, just repeat step S20-N times, where N is a natural number greater than or equal to 1.

[0082] Specifically, step S2 is based on a photolysis cooperative electrochemical treatment device, the device includes a device body, which is provided with a plurality of anodes, a plurality of cathodes and a reference electrode to form a three-electrode multi-channel electric field, and the anode adopts a photocatalyst loaded The carrier is a titanium mesh, and the cathode is a titanium mesh with the same area. The area of the anode and cathode plates is determined according to the ...

Embodiment 2

[0103] A method for treating waste water through photolysis and electrical reaction, characterized in that the process comprises the following steps:

[0104] Step S1: electrocoagulation air flotation sedimentation treatment of printing and dyeing wastewater;

[0105] Step S2: the printing and dyeing wastewater treated in step S1 is treated by photolysis and electrochemical reaction;

[0106] Step S3, just repeat step S20-N times, where N is a natural number greater than or equal to 1.

[0107] Specifically, step S2 is based on a photolysis cooperative electrochemical treatment device, the device includes a device body, which is provided with a plurality of anodes, a plurality of cathodes and a reference electrode to form a three-electrode multi-channel electric field, and the anode adopts a photocatalyst loaded Titanium mesh, the cathode is titanium mesh with the same area, the area of the anode and cathode plates is determined according to the volume of the device body, t...

Embodiment 3

[0128] A method for treating waste water through photolysis and electrical reaction, characterized in that the process comprises the following steps:

[0129] Step S1: electrocoagulation air flotation sedimentation treatment of printing and dyeing wastewater;

[0130] Step S2: the printing and dyeing wastewater treated in step S1 is treated by photolysis and electrochemical reaction;

[0131] Step S3, just repeat step S20-N times, where N is a natural number greater than or equal to 1.

[0132] Specifically, step S2 is based on a photolysis cooperative electrochemical treatment device, the device includes a device body, which is provided with a plurality of anodes, a plurality of cathodes and a reference electrode to form a three-electrode multi-channel electric field, and the anode adopts a photocatalyst loaded Titanium mesh, the cathode is titanium mesh with the same area, the area of the anode and cathode plates is determined according to the volume of the device body, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com