Waterproof mortar and preparation method thereof

A technology of waterproof mortar and quartz sand, which is applied in the field of building materials, can solve the problems of insufficient bonding strength between waterproof mortar and base layer, insufficient durability to meet the needs of society, weak compressive and flexural strength, etc. The effect of strong junction strength and film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

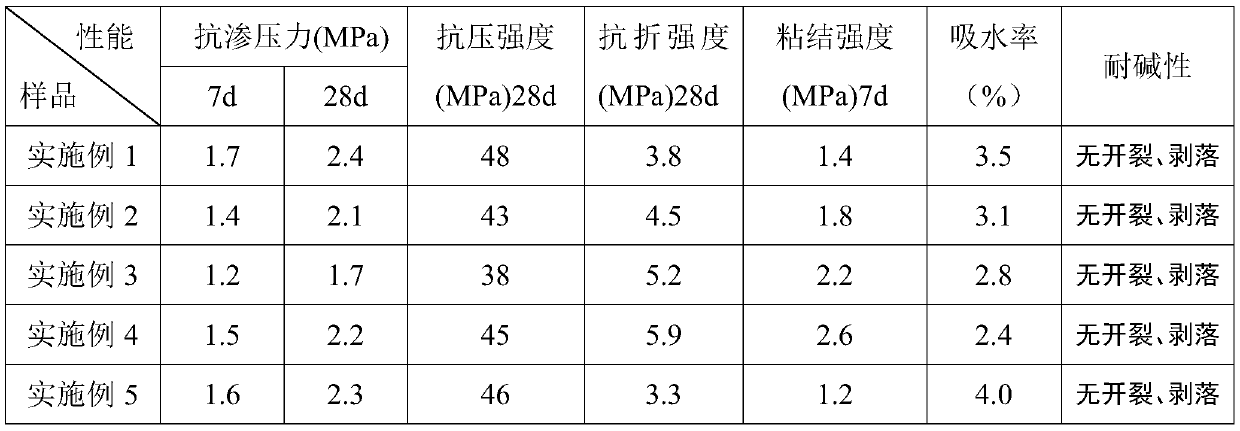

Examples

Embodiment 1

[0020] A kind of waterproof mortar, comprises the raw material of following parts by weight (each part by weight is counted as 1g): 100 parts of ordinary portland cement of 52.5 strength grade, 35 parts of cationic neoprene latex (solid content is 48%), 0.3 part of Pingpingjia 102. 0.06 part of ammonium sulfide, 0.1 part of citric acid, 0.1 part of rhamnolipid, 0.05 part of silicone high-efficiency defoamer, 0.3 part of basalt fiber (6mm particle size), 200 parts of quartz sand, 18 parts of water. Among them, Pingpingjia 102 and ammonium sulfide are stabilizers, citric acid is a metal chelating agent, and rhamnolipid is a surfactant.

[0021] Its specific preparation method comprises the following steps:

[0022] 1) Mix cationic neoprene latex, Pingpingjia 102, ammonium sulfide, citric acid, rhamnolipid, organic silicon high-efficiency defoamer and water, and stir evenly to obtain a neoprene latex mixed emulsion;

[0023] 2) adding ordinary portland cement into the neoprene l...

Embodiment 2

[0025] A kind of waterproof mortar, comprises the raw material of following parts by weight (each part by weight is counted as 1g): 100 parts of ordinary Portland cement of 52.5 strength grades, 40 parts of cationic chloroprene latex (solid content is 48%), 0.6 part of Pingpingjia 102. 0.06 parts of ammonium sulfide, 0.2 parts of citric acid, 0.2 parts of rhamnolipid, 0.2 parts of silicone high-efficiency defoamer, 0.5 parts of basalt fiber (particle size 6mm), 160 parts of quartz sand, 15 parts of water. Among them, Pingpingjia 102 and ammonium sulfide are stabilizers, citric acid is a metal chelating agent, and rhamnolipid is a surfactant. Its concrete preparation method is identical with embodiment 1.

Embodiment 3

[0027] A kind of waterproof mortar, comprises the raw material of following parts by weight (each part by weight is counted as 1g): 100 parts of ordinary Portland cement of 52.5 strength grades, 44 parts of cationic neoprene latex (solid content is 48%), 0.4 part of Pingpingjia 102. 0.07 parts of ammonium sulfide, 0.3 parts of citric acid, 0.3 parts of rhamnolipid, 0.3 parts of silicone high-efficiency defoamer, 0.7 parts of basalt fiber (6mm particle size), 130 parts of quartz sand, 15 parts of water. Among them, Pingpingjia 102 and ammonium sulfide are stabilizers, citric acid is a metal chelating agent, and rhamnolipid is a surfactant. Its concrete preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap