Method for preparing silver nano particle modified titanium dioxide composite material

A technology of silver nanoparticles and titanium dioxide, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of long preparation time, high cost, complicated process, etc., and achieve low cost, mild conditions and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0023] (1) Weigh 0.05g of titanium dioxide (commercial grade P25) and add it to 10mL of silver nitrate solution with a concentration of 0.1mol / L, configure it into a suspension with a concentration (mass volume ratio concentration of titanium dioxide) of 5g / L, and stir at room temperature for 2h ;

[0024] (2) drop the suspension of gained on the carbon film support net for transmission electron microscopy, and dry naturally to prepare the sample support film;

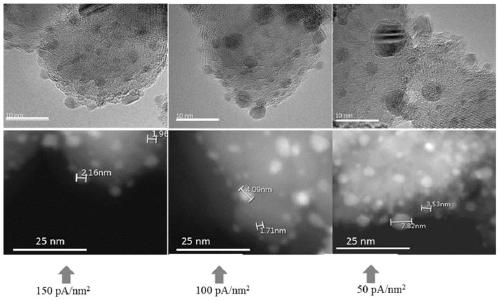

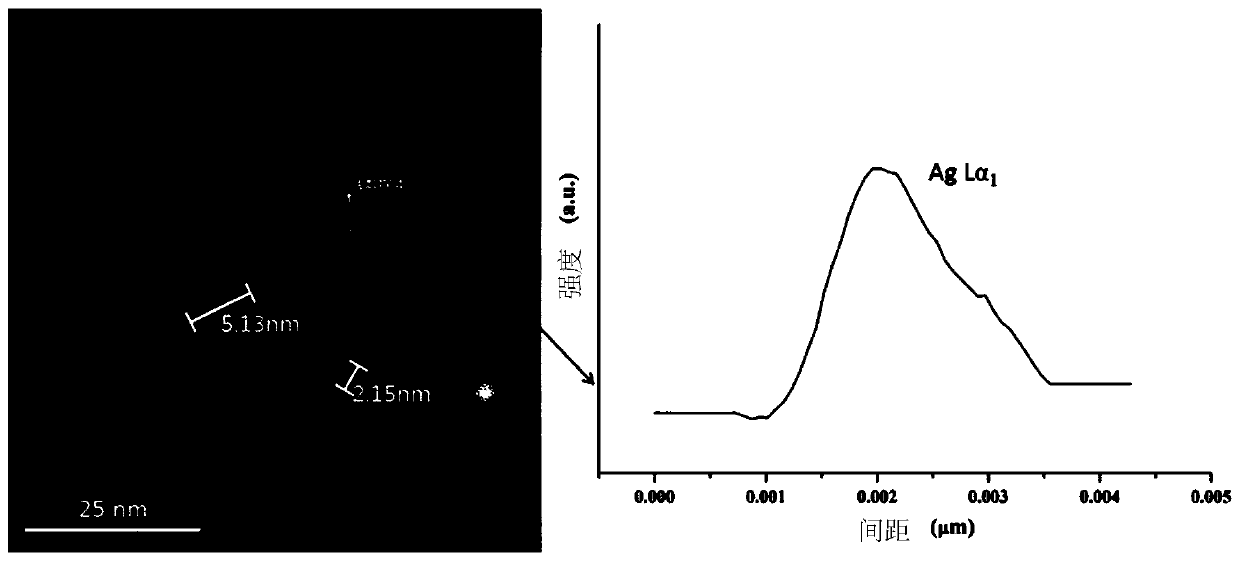

[0025] (3) Put the prepared sample support film loaded with silver ion-impregnated titanium dioxide particles into the transmission electron microscope, carry out electron beam irradiation, and control the irradiation beam intensity to be 50 / 100 / 150pA / nm respectively 2 , and the irradiation time was 60s, respectively, and the silver nanoparticle-modified titanium dioxide composite material was obtained.

[0026] See attached picture, figure 1 It is a transmission electron microscope (TEM) and a high-angle annular dar...

Embodiment II

[0029] (1) Weigh 0.5g of titanium dioxide (commercial grade P25) and add it to 10mL of silver nitrate solution with a concentration of 0.5mol / L, configure it into a suspension with a concentration (mass volume ratio concentration of titanium dioxide) of 50g / L, and stir at room temperature for 3h ;

[0030] (2) drop the suspension of gained on the carbon film support net for transmission electron microscopy, and dry naturally to prepare the sample support film;

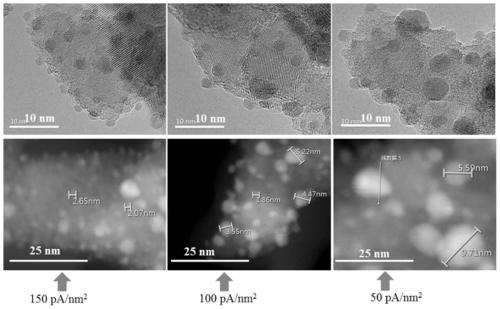

[0031] (3) Put the prepared sample support film loaded with silver ion-impregnated titanium dioxide particles into the transmission electron microscope, carry out electron beam irradiation, and control the irradiation beam intensity to be 50 / 100 / 150pA / nm respectively 2 , and the irradiation time was 60s, respectively, and the silver nanoparticle-modified titanium dioxide composite material was obtained.

[0032] See attached picture, image 3 It is a transmission electron microscope (TEM) and a high-angle annular dar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap