to sio 2 -mtes-aptes composite airgel is a method for removing thiophene sulfides in fuel oil as an adsorbent

A composite aerogel and sulfide technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as low adsorption capacity, achieve high adsorption selectivity, improve hydrophobicity, etc. The effect of increasing the property and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

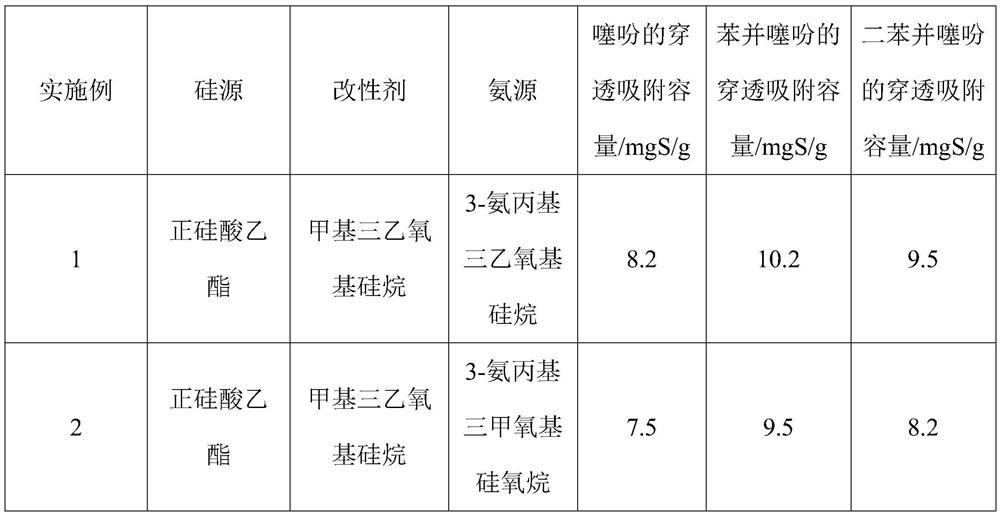

[0025] Embodiment 1-2: SiO of different ammonia sources 2- Adsorption performance of MTES-APTES composite airgel for thiophene sulfides in simulated gasoline.

[0026] In the SiO prepared by the sol-gel method with a molar ratio of silicon source and ammonia source of 3.2:1 2 -In the MTES-APTES composite airgel, the silicon source used is tetraethyl orthosilicate, and the prepared SiO 2 - MTES-APTES composite airgel is used for penetration adsorption desulfurization experiment, the specific operation is as follows: In the fixed bed reactor, the bottom layer is filled with an appropriate amount of absorbent cotton, and then filled with 1g of SiO 2 - MTES-APTES composite airgel with appropriate amount of quartz sand. Before the adsorption experiment started, the packed adsorbent was fully wetted with n-heptane. Feed simulated gasoline, collect the adsorbed simulated gasoline at the outlet of the lower end of the reactor, and carry out chromatographic analysis. When the sulfur...

Embodiment 3~7

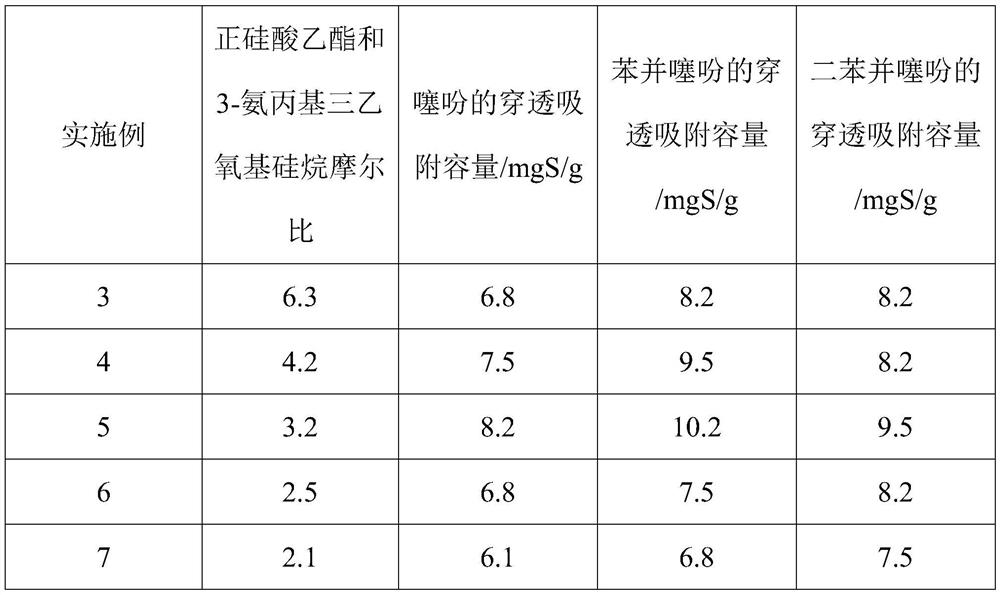

[0031] Examples 3-7: SiO with different molar ratios of orthosilicate and 3-aminopropyltriethoxysilane 2 - Adsorption performance of MTES-APTES composite airgel for thiophene sulfides in simulated gasoline. SiO with molar ratios of ethyl orthosilicate and 3-aminopropyltriethoxysilane were 6.3, 4.2, 3.2, 2.5, 2.1, respectively. 2 - MTES-APTES composite airgel was used for breakthrough adsorption experiments on thiophene sulfides in simulated gasoline. The operation of the breakthrough adsorption experiment is the same as in Examples 1-2, and the adsorption results are shown in Table 2.

[0032] Table 2 SiO with different moles of tetraethylorthosilicate and 3-aminopropyltriethoxysilane 2 - Adsorption performance of MTES-APTES composite airgel for thiophene sulfides in simulated gasoline

[0033]

[0034] As can be seen from Table 2, along with the reduction of ethyl orthosilicate and 3-aminopropyltriethoxysilane mol ratio, different ethyl orthosilicate and 3-aminopropyltr...

Embodiment 8~12

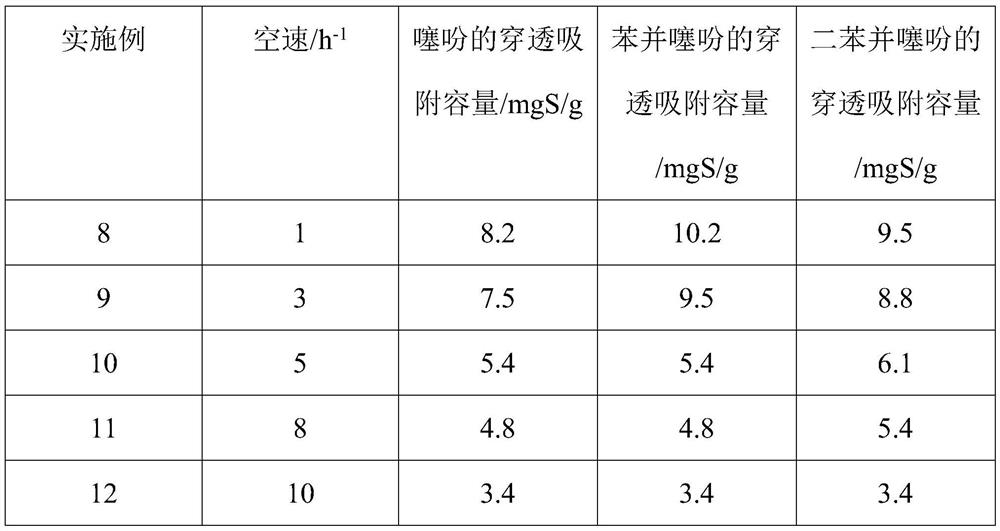

[0035] Embodiment 8~12: Different space velocity is to SiO 2 - Adsorption performance of MTES-APTES composite airgel for thiophene sulfides in simulated gasoline

[0036] SiO with a molar ratio of tetraethyl orthosilicate to 3-aminopropyltriethoxysilane of 3.2 was selected. 2 - MTES-APTES composite airgel. at an airspeed of 1h -1 、3h -1 、5h -1 、8h -1 、10h -1 Next, the breakthrough adsorption experiment was carried out on thiophene sulfides in simulated gasoline. The operation of the breakthrough adsorption experiment was the same as in Examples 1-2, and the adsorption results are shown in Table 3.

[0037] Table 3 SiO at different space velocities 2 - Adsorption performance of MTES-APTES composite airgel for thiophene sulfides in simulated gasoline

[0038]

[0039] It can be seen from Table 3 that with the decrease of space velocity, the SiO 2 -The penetration adsorption capacity of MTES-APTES composite airgel to thiophene, benzothiophene and dibenzothiophene wil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com