Alkali metal poisoning SCR denitration catalyst recycling and reusing method

A denitration catalyst and alkali metal technology, applied in the field of environmental protection technology and denitration catalysis, can solve the problems of excessive catalyst oxidation rate, unsatisfactory removal effect of catalyst surface deposits, easy alkali metal poisoning of catalysts, etc., so as to realize resource utilization and reduce The effect of crushing and reshaping steps, optimizing the microscopic pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

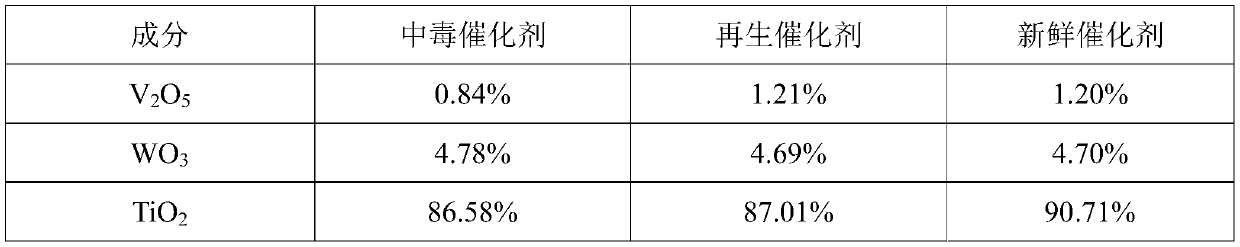

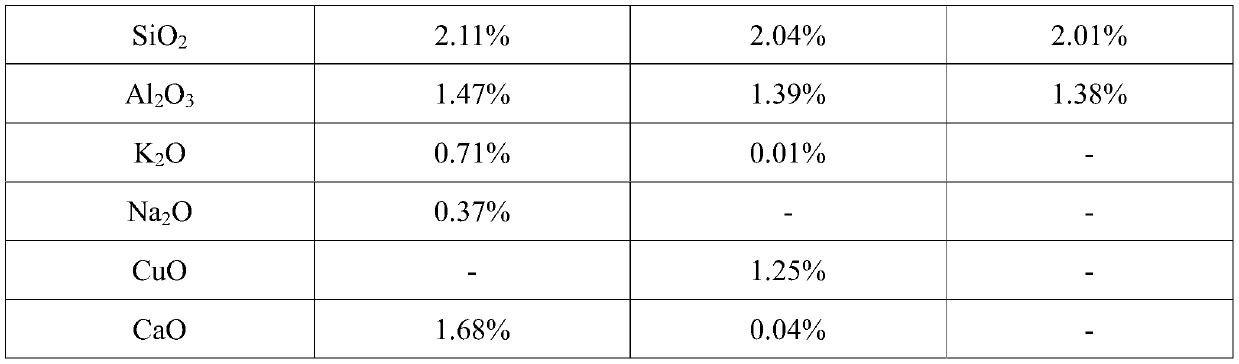

[0025] Alkali metal poisoning denitrification catalyst is V 2 o 5 -WO 3 / TiO 2 Honeycomb SCR denitrification catalyst.

[0026] 1) Deashing: Blow the catalyst with dry and clean compressed air to remove the ash on the surface of the catalyst and in the pores;

[0027] 2) Cleaning: first put the purged catalyst into a mixture containing 0.1wt% Pingpinga, 2wt% hydroxypropyl methylcellulose, 1wt% diammonium hydrogen phosphate, 1wt% sodium lignosulfonate, 0.6wt% polyacrylic acid (Molecular weight: 3000) in the cleaning solution, bubbling cleaning 2 times, cleaning time 4h / time; Then the catalyst after cleaning is put into the aqueous solution containing 0.2mol / L ethylene glycol and 5mol / L sulfuric acid to heat treatment, in React at 60°C for 24 hours; after the reaction, put the catalyst into deionized water and wash it 3 times by bubbling, and the cleaning time is 4 hours each time; the washed catalyst can be dried at 70°C for 48 hours;

[0028]3) Regeneration: first soak th...

Embodiment 2

[0038] Alkali metal poisoning denitrification catalyst is V 2 o 5 -WO 3 / TiO 2 Flat-plate SCR denitration catalyst.

[0039] 1) Deashing: Blow the catalyst with dry and clean compressed air to remove the ash on the surface of the catalyst and in the pores;

[0040] 2) Cleaning: first put the purged catalyst into a mixture containing 0.5wt% Pingpinga, 0.2wt% hydroxypropyl methylcellulose, 3wt% diammonium hydrogen phosphate, 4wt% sodium lignosulfonate, 0.2wt% poly In the cleaning solution of acrylic acid (molecular weight: 6000), bubbling and cleaning 3 times, the cleaning time is 2h / time; then the catalyst after cleaning is put into the aqueous solution containing 1mol / L ethylene glycol and 1mol / L sulfuric acid for heat treatment. React at 80°C for 6 hours; after the reaction, put the catalyst into deionized water, wash it twice by bubbling, and the cleaning time is 4 hours each time; the cleaned catalyst can be dried at 90°C for 24 hours;

[0041] 3) Regeneration: first s...

Embodiment 3

[0050] Alkali metal poisoning denitrification catalyst is V 2 o 5 -MoO 3 / TiO 2 Flat-plate SCR denitration catalyst.

[0051] 1) Deashing: Blow the catalyst with dry and clean compressed air to remove the ash on the surface of the catalyst and in the pores;

[0052] 2) Cleaning: first put the purged catalyst into a mixture containing 0.3wt% Pingpinga, 1wt% hydroxypropyl methylcellulose, 2wt% diammonium hydrogen phosphate, 2wt% sodium lignosulfonate, 0.4wt% polyacrylic acid (molecular weight: 5000) in the cleaning solution, bubbling cleaning 2 times, cleaning time 3h / time; Then the catalyst after cleaning is put into the aqueous solution containing 0.5mol / L ethylene glycol and 3mol / L sulfuric acid to heat treatment, in React at 70°C for 12 hours; after the reaction, put the catalyst into deionized water, wash it twice by bubbling, and the cleaning time is 3 hours each time; the cleaned catalyst can be dried at 85°C for 30 hours;

[0053] 3) Regeneration: first soak the cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com