Silica fume based silicon monoxide negative electrode material, preparation method thereof and lithium ion battery

A lithium-ion battery and silicon oxide technology, which is applied in the direction of silicon oxide, battery electrodes, secondary batteries, etc., can solve the problems of non-spherical shape, complex types of impurities, poor batch stability, etc., and achieve low price and high efficiency Effect of Recycling Market, Cost Reduction and Construction Price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

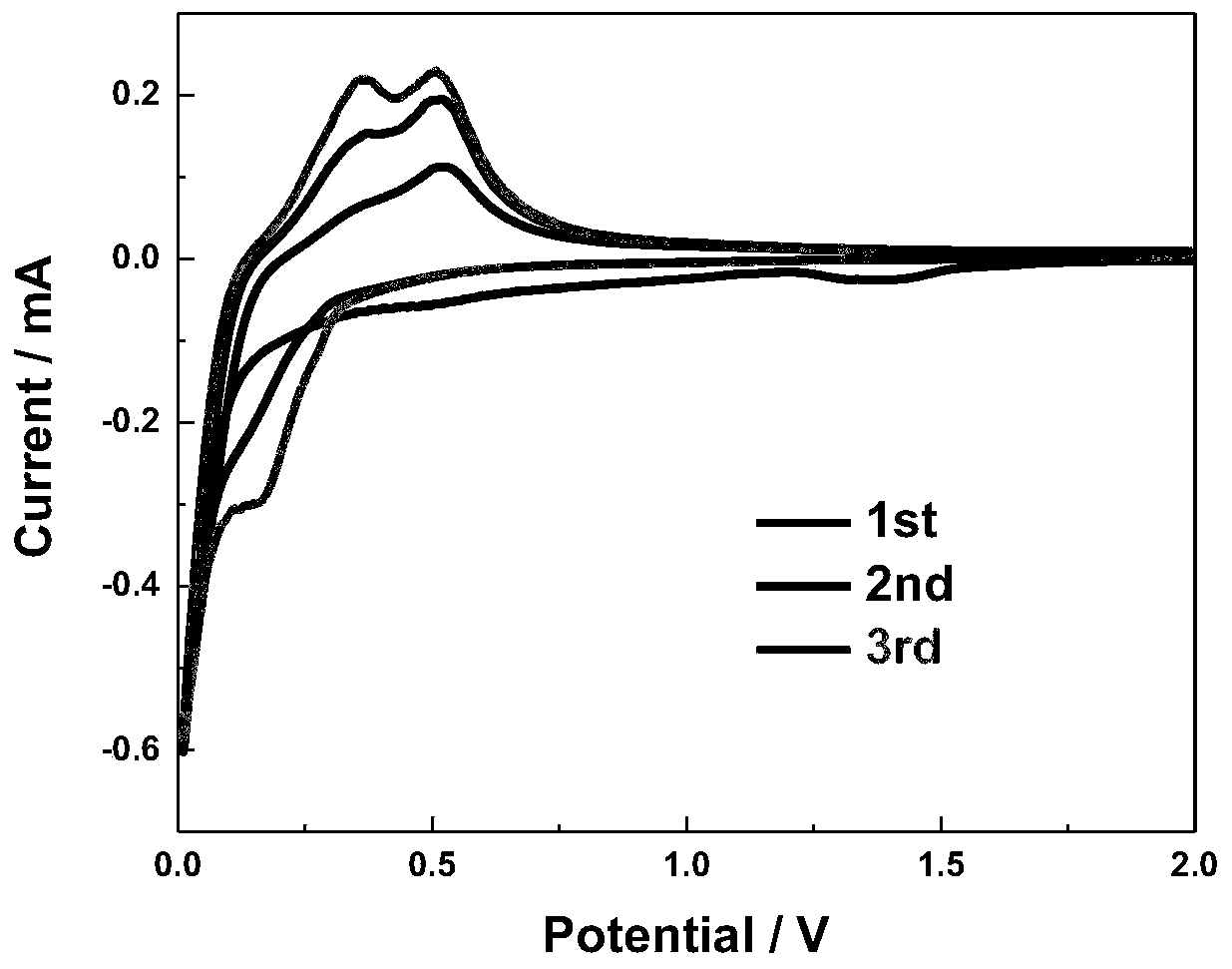

Embodiment 1

[0029] Selecting magnesium powder as an example with reducing agent, the concrete method of the present embodiment is as follows:

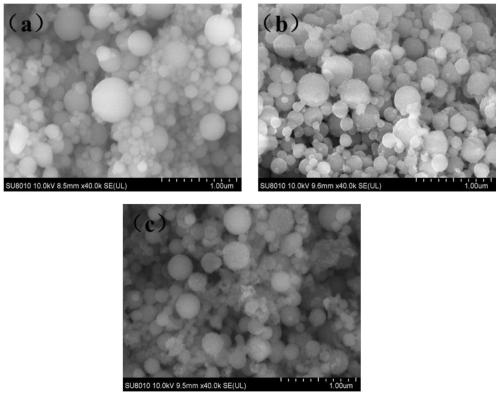

[0030] (a) Choose silica fume powder with an average particle size of 120 nanometers as a raw material, with a purity of 98%, and impurities including iron oxide, magnesium oxide, calcium oxide and a small amount of carbon.

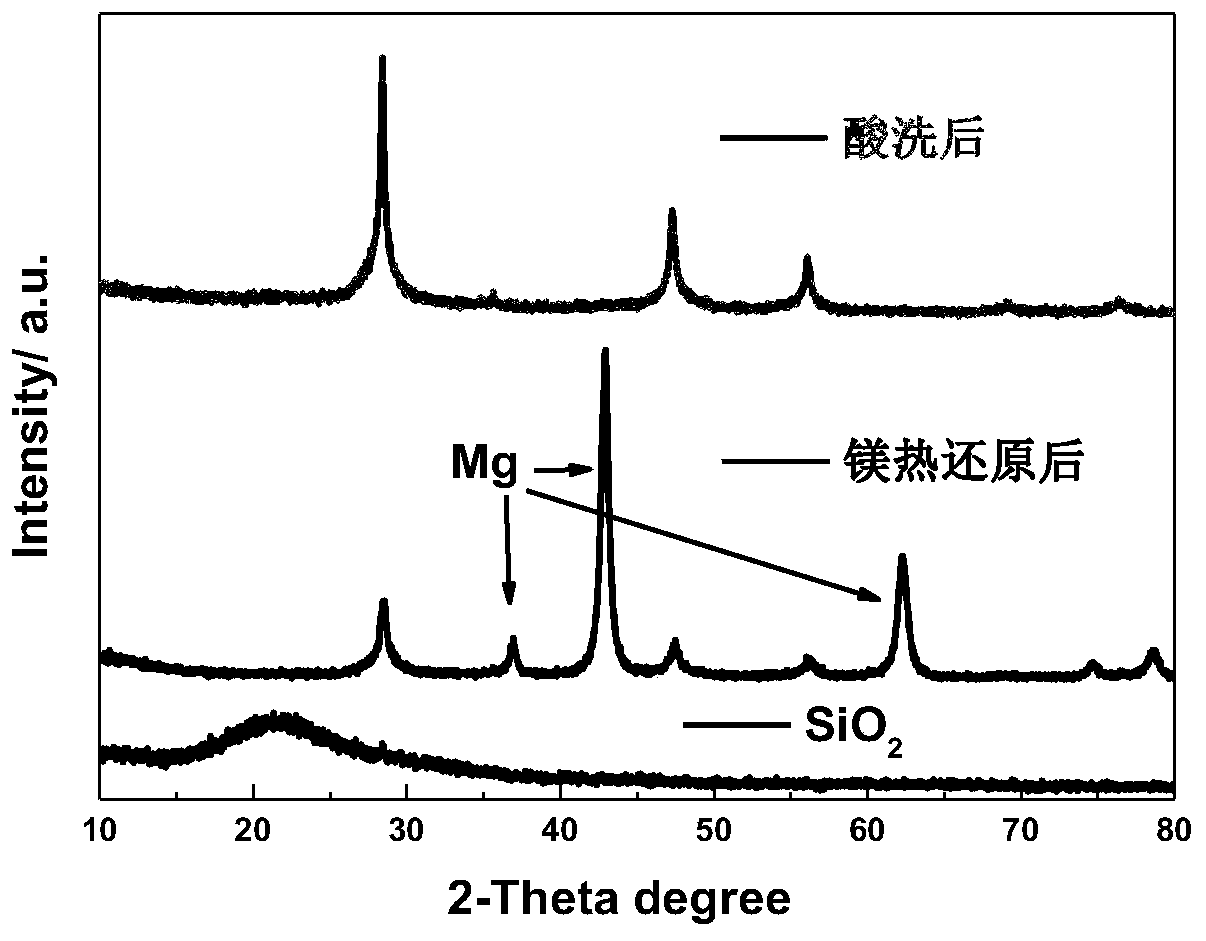

[0031] (b) Put the silica fume powder raw material into 0.1M HCl solution for high-speed stirring and washing for 1 hour, filter and wash with deionized water for 3 times until the solution is weakly acidic, and dry for later use.

[0032] (c) Grinding and mixing the acid-washed silicon fume powder raw material and magnesium powder according to the mass ratio of 1:0.8, under the protection of Ar atmosphere in the tube furnace, calcining at 650°C for 1h, and after partial reduction, SiO is obtained x Material.

[0033] (d) SiO will be obtained x Disperse the material into 0.05M HCl solution, react overnight under magnetic st...

Embodiment 2

[0035] Reductant is selected aluminum powder, and specific method is similar to embodiment 1, and difference is, after the silicon fume powder raw material after pickling and high-purity aluminum powder are ground and mixed according to the mass ratio of 1:0.6, in tube furnace Ar Under the protection of the atmosphere, calcined at 800 °C for 1.5 h to obtain partially reduced SiO x material, obtained SiO x Material dispersed to 0.1M HNO 3 In the solution, react overnight under magnetic stirring to further remove impurities and residual magnesium powder. After washing and centrifuging, dry at 120°C in vacuum to obtain high-purity and high-performance SiO x Negative material.

Embodiment 3

[0037] Reductant selects graphite carbon for use, and specific method is similar to embodiment 1, and difference is, after the silica fume powder raw material after pickling and the graphite powder of particle size 1 micron size are ground and mixed according to the mass ratio of 1:1, in Under the protection of Ar atmosphere in a tube furnace, calcined at 1200 ° C for 3 h to obtain partially reduced SiO x material, after natural cooling to 500°C, air was passed through for 3 hours to remove excess graphite carbon material to obtain high-purity and high-performance SiO x Negative material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com