Slow-release organic fertilizer and preparation method thereof

An organic fertilizer and slow-release technology, applied in the field of slow-release organic fertilizer and its preparation, can solve the problems of easy agglomeration failure and poor efficacy, and achieve the effects of increasing crop yield, promoting high and stable yield, and enhancing the effect of sustained release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

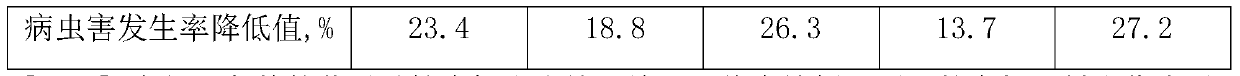

Examples

Embodiment 1

[0031] A preparation method of slow-release organic fertilizer, said preparation method comprising the following steps:

[0032] S1: Stir and mix sodium alginate, organic bentonite, PEG600, sodium citrate and deionized water at a mass ratio of 40:12:5:4:70 at a temperature of 40°C to obtain a mixed solution;

[0033] S2: The mixed solution and organic fertilizer are placed in an autoclave, the amount of organic fertilizer added is equivalent to 8.6% of the total mass of the mixed solution, carbon dioxide is introduced, and the pressure is raised to a supercritical state, and the supercritical The temperature of the state is 38°C and the pressure is 8MPa, and the mixed solution is stirred and mixed evenly under the action of supercritical carbon dioxide to form an organic fertilizer emulsion;

[0034] S3: reduce the outlet operating pressure of the autoclave, and spray the organic fertilizer emulsion obtained in step S2 from the outlet nozzle together with supercritical carbon ...

Embodiment 2

[0039] A preparation method of slow-release organic fertilizer, said preparation method comprising the following steps:

[0040] S1: Stir and mix sodium alginate, organic bentonite, PEG600, sodium citrate and deionized water at a mass ratio of 30:10:3:1:50 at a temperature of 50°C to obtain a mixed solution;

[0041] S2: The mixed solution and organic fertilizer are placed in an autoclave, the amount of the organic fertilizer added is equivalent to 5% of the total mass of the mixed solution, carbon dioxide is introduced, and the pressure is raised to a supercritical state, and the supercritical The temperature in the state is 40°C and the pressure is 8MPa, and the mixed solution is stirred and mixed evenly under the action of supercritical carbon dioxide to form an organic fertilizer emulsion;

[0042] S3: reduce the outlet operating pressure of the autoclave, and spray the organic fertilizer emulsion obtained in step S2 from the outlet nozzle together with supercritical carbon ...

Embodiment 3

[0047] A preparation method of slow-release organic fertilizer, said preparation method comprising the following steps:

[0048] S1: Stir and mix sodium alginate, organic bentonite, PEG600, sodium citrate and deionized water at a mass ratio of 50:15:8:7:100 at a temperature of 60°C to obtain a mixed solution;

[0049] S2: The mixed solution and organic fertilizer are placed in an autoclave, the amount of the organic fertilizer added is equivalent to 10% of the total mass of the mixed solution, carbon dioxide is introduced, and the pressure is raised to a supercritical state, and the supercritical The temperature in the state is 42°C and the pressure is 8.5MPa. Under the action of supercritical carbon dioxide, the mixed solution is stirred and mixed evenly to form an organic fertilizer emulsion;

[0050] S3: reduce the outlet operating pressure of the autoclave, and spray the organic fertilizer emulsion obtained in step S2 from the outlet nozzle together with supercritical carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com