Preparation method of super-hydrophobic film on surface of steel substrate

A steel substrate, super-hydrophobic technology, applied in coating, metal material coating process and other directions, can solve the problems of low wear resistance, environmental pollution, complex process, etc., to achieve good wear resistance and corrosion resistance, The effect of accelerating etching speed and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

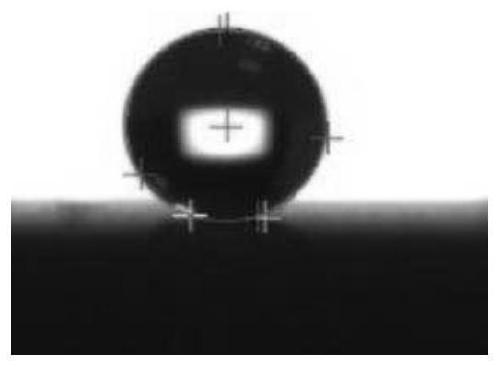

Image

Examples

Embodiment example 1

[0027] (1) Experimental operation process:

[0028] 1. Surface pre-treatment: First, put the 316L steel substrate sample in absolute ethanol and deionized water for 10 minutes, and then use 600 # , 800 # , 1200 # , 1600 # Sandpaper until the surface is smooth.

[0029] 2. Etching: Dissolve ferric fluoride in deionized water to obtain a 10%wt electrolyte solution, and then place the sample in an anodic oxidation system. The 316L steel substrate is used as the anode, and the platinum electrode is used as the cathode. 10mA / cm 2 After 20 minutes, the sample was taken out and rinsed with a large amount of deionized water until there were no air bubbles on the surface of the substrate.

[0030] 3. Modification: Prepare 0.01mmol / L stearic acid and 0.01mmol / L perfluorooctyltrimethoxysilane ethanol solution, place the above-mentioned etched steel substrate in the solution for modification for 1 hour, and then take it out.

[0031] 4. Heat treatment: Place the sample in a crucible...

Embodiment example 2

[0035] (2) Experimental operation process:

[0036] 1. Pre-treatment: First, put the 316L steel matrix sample in absolute ethanol and deionized water for 10 minutes, and then use 600 # , 800 # , 1200 # , 1600 # Sandpaper until the surface is smooth.

[0037] 2. Etching: Dissolve ferric fluoride in deionized water to obtain a 15%wt electrolyte solution, and then place the sample in an anodic oxidation system. The 316L steel substrate is used as the anode, and the platinum electrode is used as the cathode. 20mA / cm 2 After 15 minutes, the sample was taken out and rinsed with a large amount of deionized water until there were no air bubbles on the surface of the substrate.

[0038] 3. Modification: Prepare 0.02mmol / L stearic acid and 0.02mmol / L perfluorooctyltrimethoxysilane ethanol solution, place the etched steel substrate in the solution for modification for 1.5h, and then take it out.

[0039] 4. Heat treatment: Place the sample in a crucible and dry it in an oven at 100...

Embodiment example 3

[0043] 1. Pre-treatment: First, put the 316L steel matrix sample in absolute ethanol and deionized water for 10 minutes, and then use 600 # , 800 # , 1200 # , 1600 # Sandpaper until the surface is smooth.

[0044] 2. Etching: Dissolve ferric fluoride in deionized water to obtain a 20%wt electrolyte solution, and then place the sample in an anodic oxidation system. The 316L steel substrate is used as the anode, and the platinum electrode is used as the cathode. 30mA / cm 2 Carry out anodic oxidation under the same conditions, take out the sample after 10 minutes, and rinse with a large amount of deionized water until there are no air bubbles on the surface of the substrate.

[0045] 3. Modification: Prepare 0.05mmol / L stearic acid and 0.05mmol / L perfluorooctyltrimethoxysilane ethanol solution, put the above etched steel substrate in the solution for modification for 2.0h, and then take it out.

[0046] 4. Heat treatment: Place the sample in a crucible and dry it in an oven at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com