Carbon-silicon double-shell hollow structure composite microsphere and preparation method thereof and application

A technology of composite microspheres and double shells, applied in structural parts, active material electrodes, electrical components, etc., can solve problems such as unsuitable for industrial promotion, low utilization rate, and environmental pollution, so as to improve commercial value, reduce pollution, The effect of simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

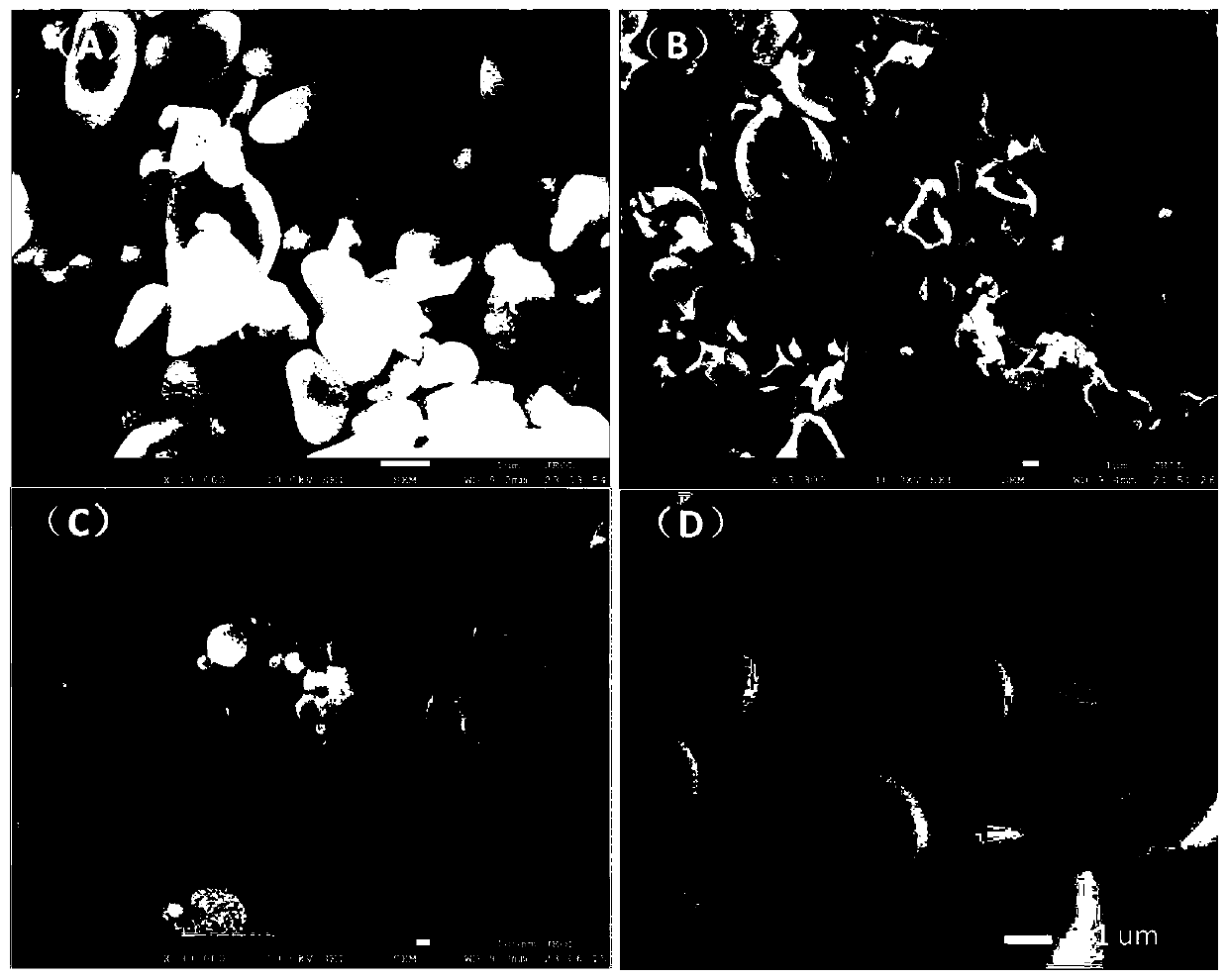

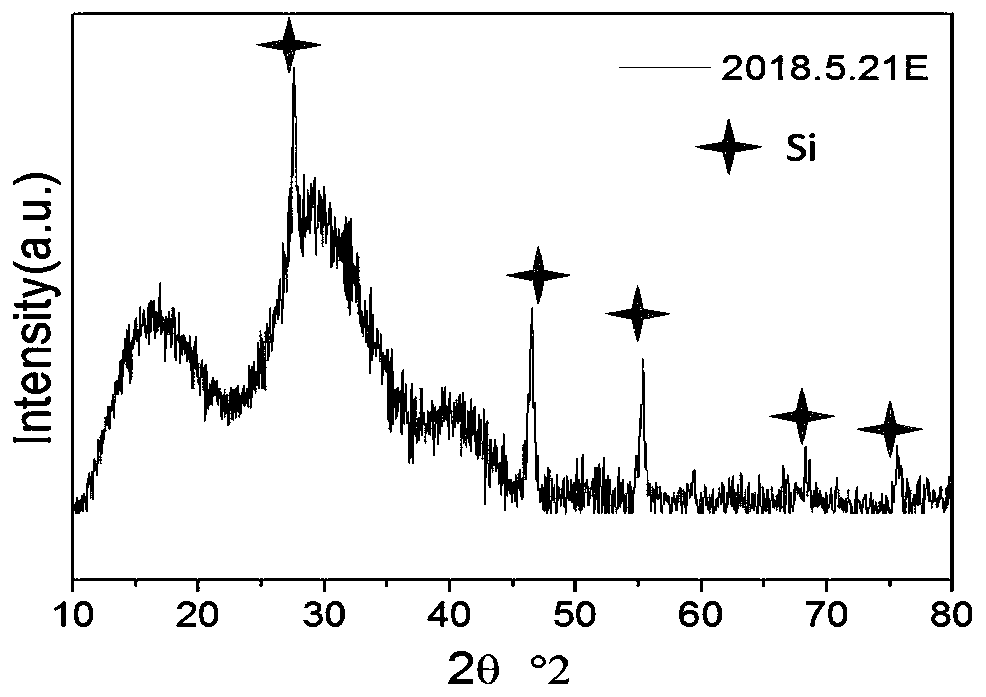

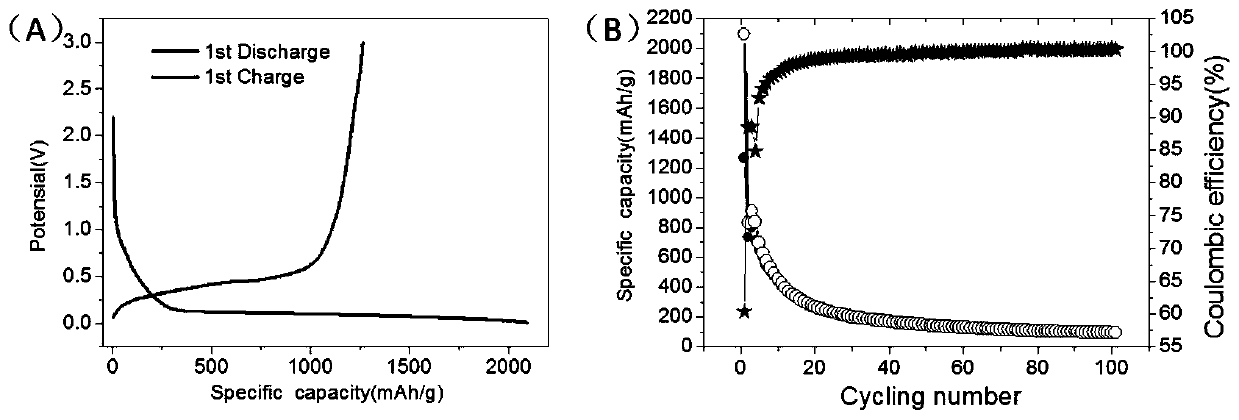

Image

Examples

Embodiment 1

[0034] A carbon-silicon double-shell hollow structure composite microsphere is prepared through the following steps:

[0035] (1) After acid leaching fly ash and sulfuric acid at 120°C, filter and separate, the obtained solid is the acid leaching residue of fly ash; mix and stir the acid leaching residue of fly ash and sodium hydroxide solution to obtain silicic acid Sodium solution, centrifuged to remove the precipitate, to obtain the clear liquid, take 5mL of the clear liquid and weigh M1, then dry in an oven to obtain the solid M2, calculate the solid content of the clear liquid m=M2 / M1, take the surfactant according to the ratio of 0.5% m Add hexadecyltrimethylammonium bromide into the clear liquid, continue to stir and dissolve to obtain a clear solution, and then spray dry it at an inlet temperature of 140°C and an outlet temperature of 80°C to obtain a white powder A;

[0036] (2) Dissolve the white powder A in distilled water, add hydrochloric acid dropwise, adjust the...

Embodiment 2

[0040] A carbon-silicon double-shell hollow structure composite microsphere is prepared through the following steps:

[0041] (2) After acid leaching fly ash and hydrochloric acid at 140°C, filter and separate, the obtained solid is acid leaching residue of fly ash; mix and stir fly ash acid leaching residue and potassium hydroxide solution to obtain silicic acid Potassium solution, centrifuged to remove the precipitate, to obtain the clear liquid, take 5mL of the clear liquid and weigh M1, then dry in an oven to obtain the solid M2, calculate the solid content of the clear liquid m=M2 / M1, take the surfactant according to the ratio of 10% m Add sodium dodecylbenzenesulfonate polyvinylpyrrolidone into the clear liquid, continue to stir and dissolve to obtain a clear solution, and then spray dry it at an inlet temperature of 200°C and an outlet temperature of 120°C to obtain a white powder A;

[0042] (2) Dissolve white powder A in distilled water, add sulfuric acid dropwise, ad...

Embodiment 3

[0046] A carbon-silicon double-shell hollow structure composite microsphere is prepared through the following steps:

[0047] (3) After acid leaching fly ash and sulfuric acid or hydrochloric acid at 130°C, filter and separate, and the obtained solid is acid leaching residue of fly ash; mix and stir fly ash acid leaching residue and sodium hydroxide solution to obtain Sodium silicate solution, centrifuge to remove the precipitate, get the clear liquid, take 5mL clear liquid and weigh M1, then dry in an oven to obtain solid M2, calculate the clear liquid solid content m=M2 / M1, take the surface according to the ratio of 8% m Add the active agent polyethylene glycol into the clear liquid, continue to stir and dissolve to obtain a clear solution, and then spray dry it at an inlet temperature of 160°C and an outlet temperature of 100°C to obtain a white powder A;

[0048] (2) Dissolve the white powder A in distilled water, add hydrochloric acid dropwise, adjust the pH<4, filter wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com