A kind of efficient nitrogen reduction cobalt manganese oxide catalyst and preparation method thereof

A technology of cobalt manganese oxide and catalyst, which is applied in the field of high-efficiency nitrogen reduction cobalt manganese oxide catalyst and its preparation field, can solve the problems of low yield of synthetic ammonia, low Faradaic efficiency, etc., and achieves increased specific surface area, improved nitrogen reduction performance, The effect of increasing catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

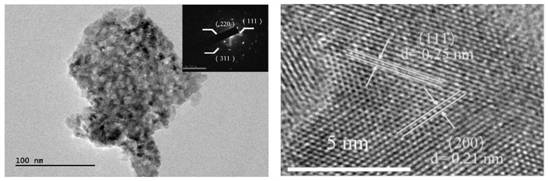

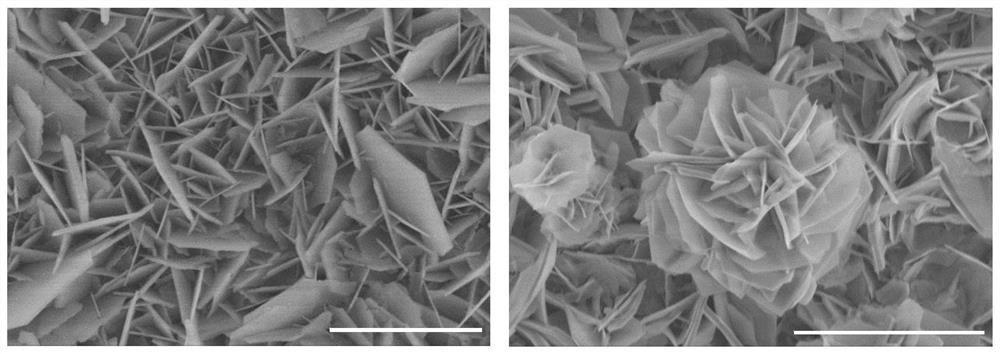

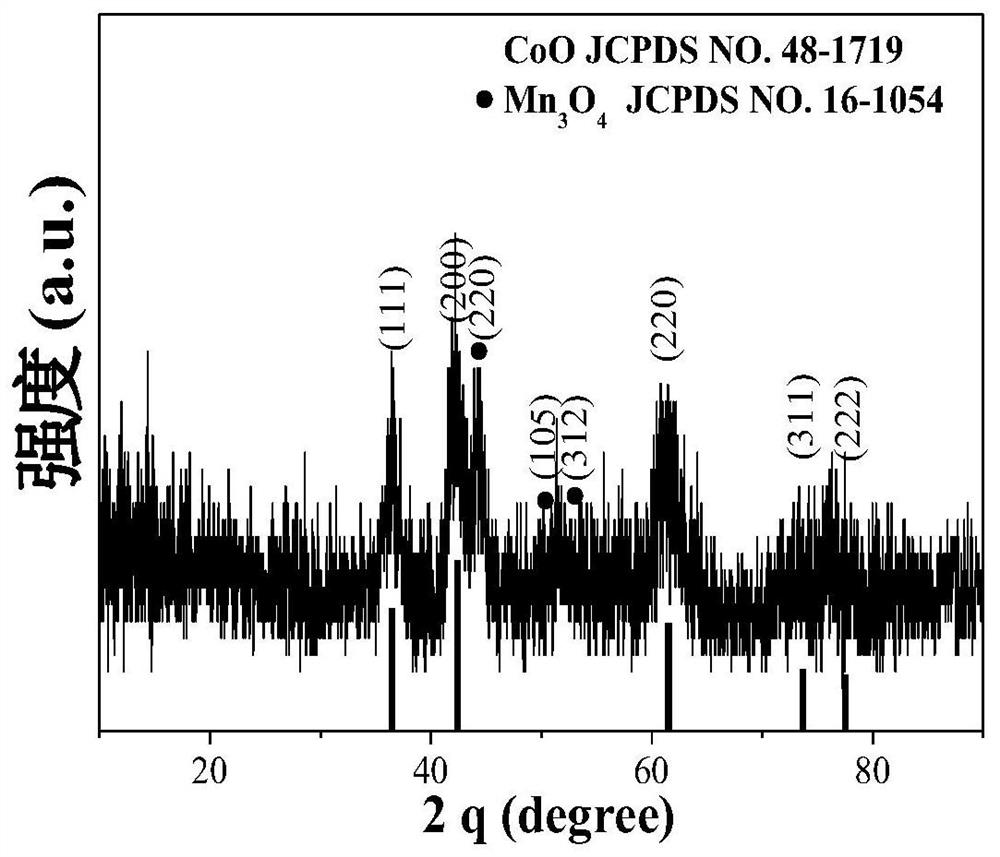

Examples

Embodiment 1

[0029] Step 1, take 9.7806g of pure aluminum (Al), 3.5516g of pure cobalt (Co), 1.6678g of pure manganese (Mn), a total of 12g samples, mix the 12g samples evenly, place them in an argon smelting furnace, and pump them down with a mechanical pump Vacuum to 1×10 -1 After Pa, turn off the mechanical pump and turn on the molecular pump to draw a high vacuum to 2.3×10 -3 Finally, the molecular pump is turned off, and the high-purity argon protective gas is introduced. The melting time of the raw material is 160s, and the front and back are smelted 5-6 times, so that the internal components of the alloy are fully mixed and evenly obtained. 80 co 13.3 mn 6.7 alloy ingot.

[0030] Step 2, after fully cooling, take out the alloy ingot and cut it into pieces, take 3g of it and clean it ultrasonically with absolute ethanol and dry it, then place it in a clean quartz tube, install it in a strip machine, and then vacuum it to 7.8 ×10 -3 After Pa, turn off the vacuum, adjust the coppe...

Embodiment 2

[0041] Step 1, according to the atomic percentage of pure aluminum is 80%, the atomic percentage of pure cobalt is 10%, and the atomic percentage of pure manganese is 10%. -1 After Pa, turn off the mechanical pump and turn on the molecular pump to draw a high vacuum to 2.0×10 -3 Finally, the molecular pump is turned off, and high-purity nitrogen protective gas is introduced. The melting time of the raw material is 240s, and the front and back are smelted 5-6 times, so that the internal components of the alloy are fully mixed and evenly obtained. 80 co 10 mn 10 alloy ingot.

[0042] Step 2, after cooling down sufficiently, take out the alloy ingot and cut it into pieces, take 3g of it and ultrasonically clean and dry it with anhydrous ethanol, place it in a clean quartz tube, install it in a strip machine, and then vacuumize it to 1 ×10 -2 After Pa, turn off the vacuum, adjust the copper roller speed to 2500 rpm, control the pressure difference between the quartz tube and t...

Embodiment 3

[0045] Step 1, according to the atomic percentage of pure aluminum is 70%, the atomic percentage of pure cobalt is 15%, and the atomic percentage of pure manganese is 15%, and the ingredients are placed in the argon melting furnace, and the mechanical pump is low vacuumed to 1×10 -1 After Pa, turn off the mechanical pump and turn on the molecular pump to pump a high vacuum to 3.0×10 -3 Finally, the molecular pump is turned off, and the high-purity helium protective gas is introduced. The melting time of the raw material is 120s, and the front and back are smelted 5-6 times, so that the internal components of the alloy are fully mixed and evenly obtained. 70 co 15 mn 15 alloy ingot.

[0046] Step 2, after cooling down sufficiently, take out the alloy ingot and cut it into pieces, take 3g of it and ultrasonically clean and dry it with anhydrous ethanol, place it in a clean quartz tube, install it in a strip machine, and then vacuumize it to 1 ×10 -2 After Pa, turn off the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com