Method for purifying phosphoric acid raffinate and recovering magnesium ammonium phosphate hexahydrate

A technology of ammonium phosphate hexahydrate and raffinate acid, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of long process flow, large loss of phosphorus, low efficiency, etc., shorten the process flow, suppress phosphorus Loss, the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

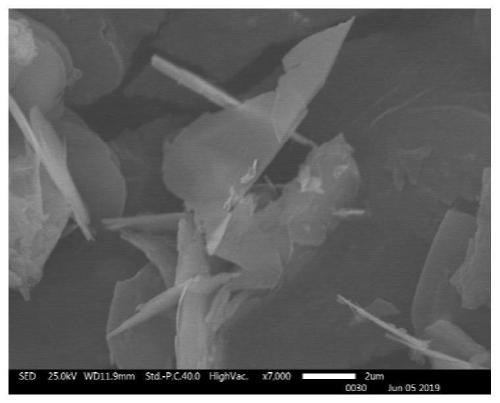

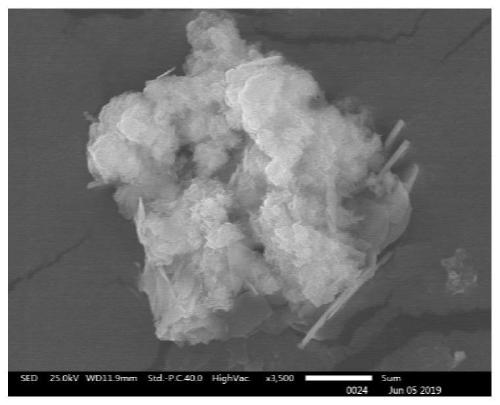

Image

Examples

Embodiment 1

[0033] A method for purifying phosphoric acid raffinate and recovering magnesium ammonium phosphate hexahydrate. The concrete steps of the method described in this embodiment are:

[0034] Step 1. Dilution

[0035] According to the mass ratio of phosphoric acid raffinate: water is 1: (0.1 ~ 0.15), the water is added to the phosphoric acid raffinate, stirred at room temperature for 0.5 ~ 0.7h, to obtain diluted phosphoric acid raffinate .

[0036] Step 2. Remove iron and aluminum

[0037] According to the mass ratio of urea: the diluted phosphoric acid raffinate is (0.5 ~ 1) : 1, the urea is added to the diluted phosphoric acid raffinate, stirred at 70 ~ 80 ° C to pH The value is 5-5.4, cooled to normal temperature, separated from solid and liquid, and washed to obtain iron-removing aluminum liquid and iron-containing aluminum slag.

[0038] Step 3. Recovery of Magnesium

[0039]The iron-removing aluminum solution is stirred at 70-80°C until the pH value is 6-6.4, cooled t...

Embodiment 2

[0041] A method for purifying phosphoric acid raffinate and recovering magnesium ammonium phosphate hexahydrate. The concrete steps of the method described in this embodiment are:

[0042] Step 1. Dilution

[0043] According to the mass ratio of phosphoric acid raffinate: water is 1: (0.15 ~ 0.2), the water is added to the phosphoric acid raffinate, stirred at room temperature for 0.6 ~ 0.8h, to obtain diluted phosphoric acid raffinate .

[0044] Step 2. Remove iron and aluminum

[0045] According to the mass ratio of urea: the diluted phosphoric acid raffinate is (1 ~ 1.5): 1, the urea is added to the diluted phosphoric acid raffinate, and stirred at 80 ~ 90 ° C to pH The value is 5.2-5.6, cooled to normal temperature, separated from solid and liquid, and washed to obtain iron-removing aluminum liquid and iron-containing aluminum slag.

[0046] Step 3. Recovery of Magnesium

[0047] Stir the iron-removing aluminum solution at 80-90°C until the pH value is 6.2-6.6, cool t...

Embodiment 3

[0049] A method for purifying phosphoric acid raffinate and recovering magnesium ammonium phosphate hexahydrate. The concrete steps of the method described in this embodiment are:

[0050] Step 1. Dilution

[0051] According to the mass ratio of phosphoric acid raffinate: water is 1: (0.2-0.3), the water is added to the phosphoric acid raffinate, and stirred at normal temperature for 0.8-1 h to obtain diluted phosphoric acid raffinate.

[0052] Step 2. Remove iron and aluminum

[0053] According to the mass ratio of urea: the diluted phosphoric acid raffinate is (1.5 ~ 2): 1, the urea is added to the diluted phosphoric acid raffinate, stirred at 90 ~ 100 ° C to pH The value is 5.6-6, cooled to normal temperature, separated from solid and liquid, and washed to obtain iron-removing aluminum liquid and iron-containing aluminum slag.

[0054] Step 3. Recovery of Magnesium

[0055] The iron-removing aluminum solution is stirred at 90-100° C. until the pH value is 6.6-7, cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com