Patents

Literature

39results about How to "Avoid coprecipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

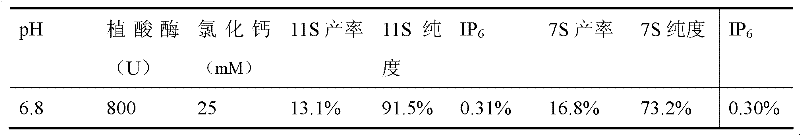

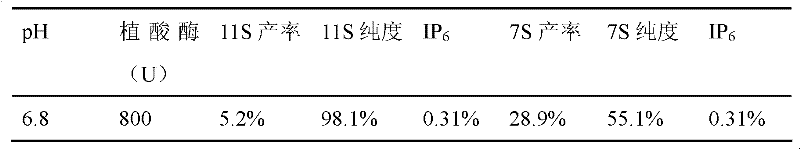

Method for fractionation of soybean 7S globulins and 11S globulins of low phytic acid

InactiveCN102229644AReduce precipitationAvoid coprecipitationPeptide preparation methodsPlant peptidesChemistryInositol Hexakisphosphate

The invention discloses a method for fractionation of soybean 7S globulins and 11S globulins of low phytic acid, which comprises the following steps of: dissolving degreased soybean meal in 10-20 times weight of water, controlling pH value, extracting and separating at the room temperature to remove bean dregs and then obtain a soybean protein extracting solution; adjusting the pH value of the soybean protein extracting solution to 3.0-6.8 in weak acid, adding phytase, carrying out enzyme treatment for 5 minutes to 3 hours at the temperature of 20-70 DEG C to obtain an enzymolysis protein solution; adding a calcium or magnesium ion precipitator in the enzymolysis protein solution, controlling the concentration of calcium or magnesium ions in the enzymolysis protein solution to 5-25mM, adjusting pH to 5.8-6.8, and carrying out centrifugal separation on fractions containing the 7S globulins and fractions containing the 11S globulins. The method disclosed by the invention has the advantages of realizing the accurate separation of the insoluble 11S globulins and the soluble 7S globulins in the higher pH value condition and obtaining two components capable of obviously reducing the content of phytic acid.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of chemical adsorption material for removing phosphorus containing substances in wastewater

InactiveCN102773084AAvoid coprecipitationAvoid pollutionOther chemical processesCombustible gas purificationChemical reactionAcid washing

The invention relates to a preparation method of a chemical adsorption material for removing phosphorus containing substances in wastewater, and belongs to the field of wastewater treatment. The preparation method includes the steps: firstly, grinding magnesite into powder and generating deposits after acid washing and alkaline leaching; mixing the deposits with 3-4% of polymerized organic polyacrylonitrile, 15-20% of polycaprolactam and 3-4% of diammonium nitrogen-based benzene solution of foaming agents; and generating the adsorption material with free Mg2+ under the pressure of 2.0-3.0MPa and at the temperature of 90-100 DEG C. Firstly, the adsorption material is soaked by phosphoric acid and then placed into an adsorption tower by serving as packing; secondly, the wastewater containing ammonium ions flows through the adsorption tower and chemically reacts with the adsorption material in the packing tower; and finally, white crystalline magnesium ammonium phosphate is generated. The influence of side reaction is avoided by the adsorption material, phosphate deposits with high purity are obtained, and secondary pollution caused by a traditional precipitation method is avoided.

Owner:CHANGZHOU UNIV

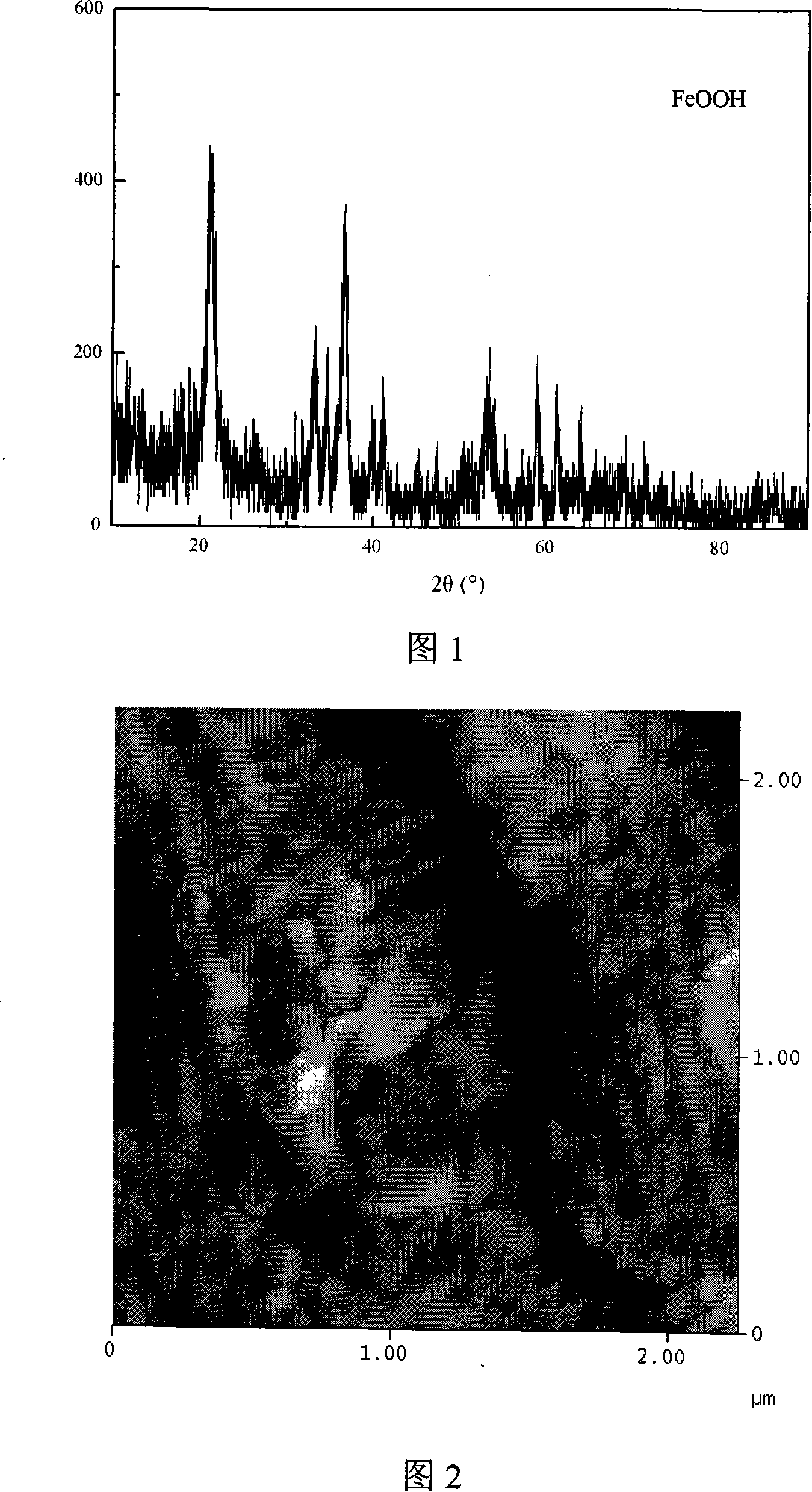

Hydroxylation iron catalyzer, preparation method and application thereof

InactiveCN101172231AUniform supersaturationUniform particle size distributionIron oxides/hydroxidesMetal/metal-oxides/metal-hydroxide catalystsHigh activationPollution

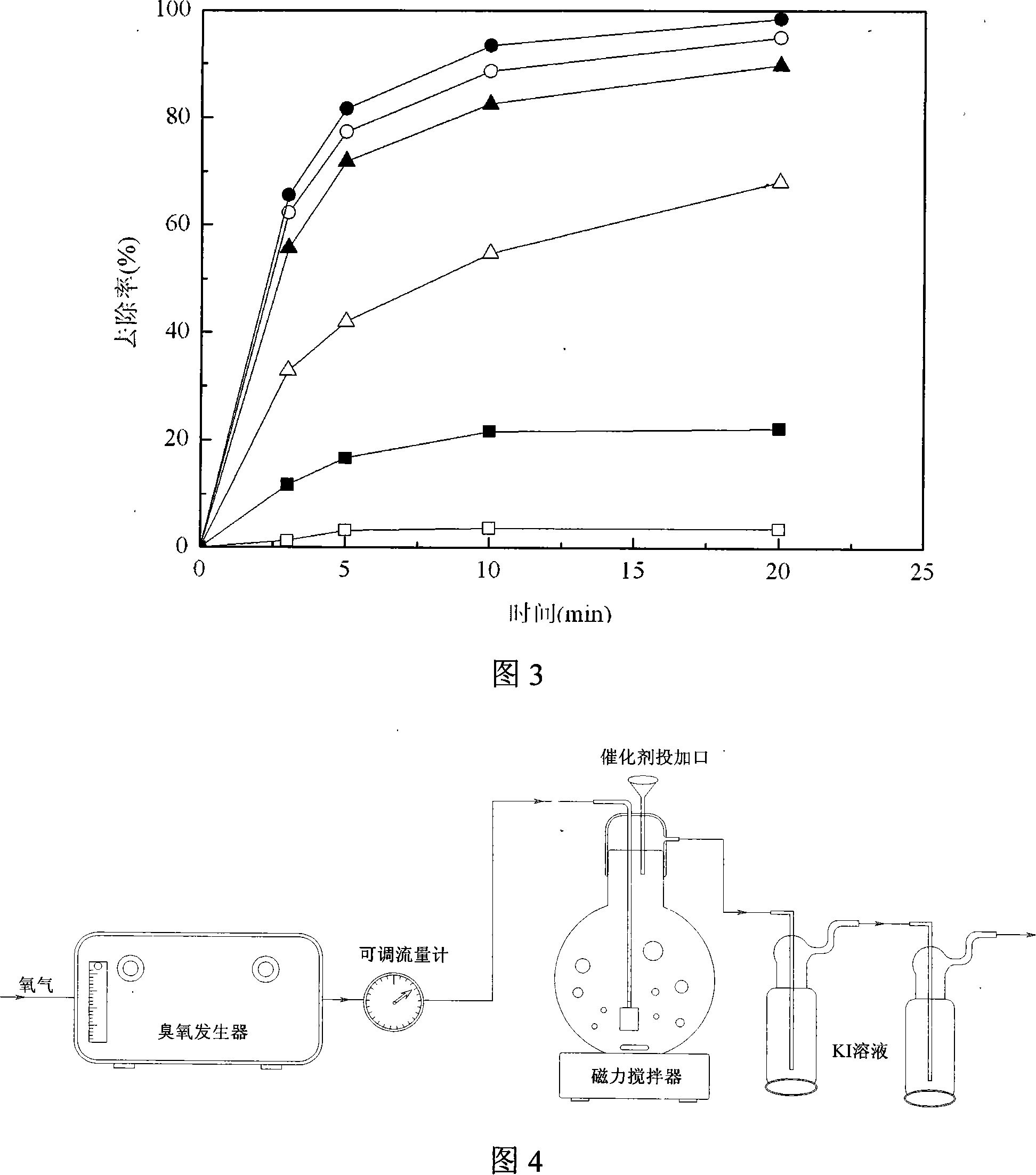

The invention discloses hydroxylation iron catalyst, and a preparation method and the application thereof, which relates to solid catalyst and the preparation method thereof. The invention solves the problems existing in the prior multiphase catalytical ozonized water treatment process that the catalytic activity of the catalyst is low, the stability is poor, and the secondary pollution is caused by the stripping of the metal ion. The hydroxylation iron catalyst of the invention is made of dissoluble ferric iron salt solution and alkali solution according to the mol ratio of 1: 3 to 4 of Fe<+3> and OH<-> and by adopting the homogeneous precipitation method, the invention is used for treating drinking water by catalytical ozonizing. The method of the invention is simple and convenient for operation, and the crystal form of the particle of the obtained product is complete, uniform and dense, and the distribution of the particle diameter is uniform. The catalyst of the invention can remove the organic pollutant difficult to be degraded in drinking water by catalytical ozonizing within the range of the pH equal to 4 to 10; the high activation of the catalyst is high and the capacity of removing trace amount of organic pollutant difficult to be degraded is strong; the stability is high, and the catalyst is uneasy to be digested and can be recurrently used to reduce the cost, and is uneasy to cause the secondary pollution.

Owner:HARBIN INST OF TECH

Method for producing nano zinc oxide and calcium carbonate compound by utilizing zinc-containing raw ore

InactiveCN108862372ARealize economic and environmental protection utilizationEfficient extractionCalcium/strontium/barium carbonatesMaterial nanotechnologyHigh pressureSteaming

The invention relates to a method for producing a nano zinc oxide and calcium carbonate compound by utilizing zinc-containing raw ore. The method comprises an extraction step, an optional purificationstep, a precipitation step, an optional rinsing step and a drying and calcination step. According to the method provided by the invention, wet-process leaching and a synthesis technology are combinedto realize economical and environment-friendly utilization of low-grade zinc oxide ore and an applicable range is wide; ammonia steaming is not needed and the method is simple and feasible; the energy consumption of a technology is greatly reduced; water treatment pressure, high-temperature and high-pressure potential safety hazards and equipment corrosion problems and the like, which are causedby the ammonia steaming, are also avoided; an obtained compound product can be directly used as a product and also can be used as a raw material for other industrial processes; the method provided bythe invention has small pollution and auxiliary materials are recyclable; the method has the advantages of energy saving, low investment, low cost and high yield.

Owner:CHONGQING DONGQUN TECH CO LTD

Method for producing nano zinc oxide by utilizing zinc-containing raw ore under zinc-ammonia complexing environment

InactiveCN108862370ARealize economic and environmental protection utilizationEfficient extractionZinc oxides/hydroxidesEnvironmental resistanceDecomposition

The invention relates to a method for producing nano zinc oxide by utilizing zinc-containing raw ore. The method comprises a primary extraction step, an optional purification step, a pre-treatment step, a zinc precipitation step, a primary calcination step, a secondary extraction step, a pressurizing and crystallization step, a decompression and decomposition step, an optional rinsing step and a secondary calcination step. According to the method disclosed by the invention, wet-process leaching and a synthesis technology are combined to realize economical and environment-friendly utilization of low-grade zinc oxide ore and an applicable range is wide; ammonia steaming is not needed and the method is simple and feasible; the energy consumption of a technology is greatly reduced; high-temperature and high-pressure potential safety hazards and equipment corrosion problems, which are caused by the ammonia steaming, are also avoided; the problems of technological recovery rate and high-quality product grade are solved; the pollution is small and materials are recyclable; the synthesis of calcium zincate under a zinc-ammonia environment is realized for the first time; a nano zinc oxide product is produced through the calcium zincate; decomposition conditions of ammonium carbonate are creatively utilized in the technology and cyclic utilization of carbon dioxide is realized through pressure difference.

Owner:CHONGQING DONGQUN TECH CO LTD

Method for producing zinc oxide by utilizing zinc-containing raw ore under zinc-ammonia complexing environment

InactiveCN108866331ARealize economic and environmental protection utilizationEfficient extractionZinc oxides/hydroxidesProcess efficiency improvementDecompositionHigh pressure

The invention relates to a method for producing zinc oxide by utilizing zinc-containing raw ore. The method comprises a primary extraction step, an optional purification step, a pre-treatment step, azinc precipitation step, a primary calcination step, a secondary extraction step, a pressurizing and crystallization step, a decompression and decomposition step, an optional rinsing step and a secondary calcination step. According to the method disclosed by the invention, wet-process leaching and a synthesis technology are combined to realize economical and environment-friendly utilization of low-grade zinc oxide ore and an applicable range is wide; ammonia steaming is not needed and the method is simple and feasible; the energy consumption of a technology is greatly reduced; high-temperatureand high-pressure potential safety hazards and equipment corrosion problems, which are caused by the ammonia steaming, are also avoided; the problems of technological recovery rate and high-quality product grade are solved; the pollution is small and materials are recyclable; the synthesis of calcium zincate under a zinc-ammonia environment is realized for the first time; a zinc oxide product isproduced through the calcium zincate; decomposition conditions of ammonium carbonate are creatively utilized in the technology and cyclic utilization of carbon dioxide is realized through pressure difference.

Owner:CHONGQING DONGQUN TECH CO LTD

Method for producing zinc oxide by utilizing zinc-containing raw ore

InactiveCN108862371ARealize economic and environmental protection utilizationEfficient extractionZinc oxides/hydroxidesEnvironmental resistanceTalc / Zinc Oxide

The invention relates to a method for producing zinc oxide by utilizing zinc-containing raw ore. The method comprises an extraction step, an optional purification step, a decarburization step, a calcium zincate synthesis step, an optional rinsing step, a calcination step and a calcium and zinc separation step. According to the method provided by the invention, wet-process leaching and a synthesistechnology are combined to realize economical and environment-friendly utilization of low-grade zinc oxide ore and an applicable range is wide; ammonia steaming is not needed and the method is simpleand feasible; the energy consumption of a technology is greatly reduced; water treatment pressure, high-temperature and high-pressure potential safety hazards and equipment corrosion problems and thelike, which are caused by the ammonia steaming, are also avoided; the environment protection problem in an ammonia circulating problem that surplus water is brought by steam so that the balance of technological water is influenced is solved, and the problems of technological recovery rate and high-quality product grade are solved; the pollution is small and auxiliary materials are recyclable; thesynthesis of calcium zincate under a zinc-ammonia environment is realized for the first time; a zinc oxide product is produced through the calcium zincate.

Owner:CHONGQING DONGQUN TECH CO LTD

A method for direct vanadium precipitation from acidic multi-impurity vanadium-containing solution

ActiveCN106319214BAvoid local overconcentrationComplete crystal formProcess efficiency improvementChemical compositionPotassium

Owner:WUHAN UNIV OF SCI & TECH

Method for selectively removing and recovering copper in water by using membrane-assisted crystallization MAC process

InactiveCN109205829AAvoid pollutionMembrane specific flux recovery rate is betterWater treatment parameter controlSpecific water treatment objectivesWater qualityMembrane reactor

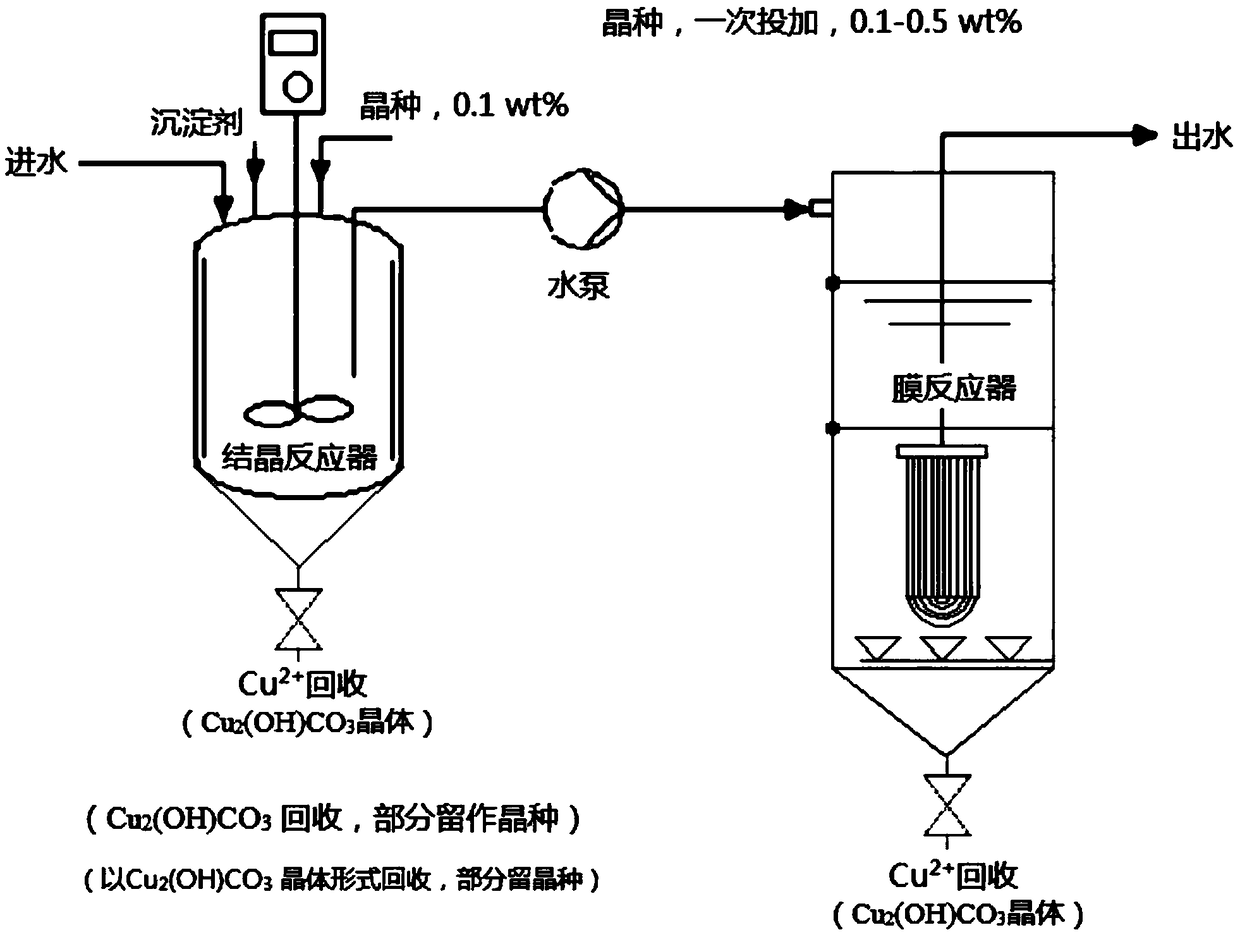

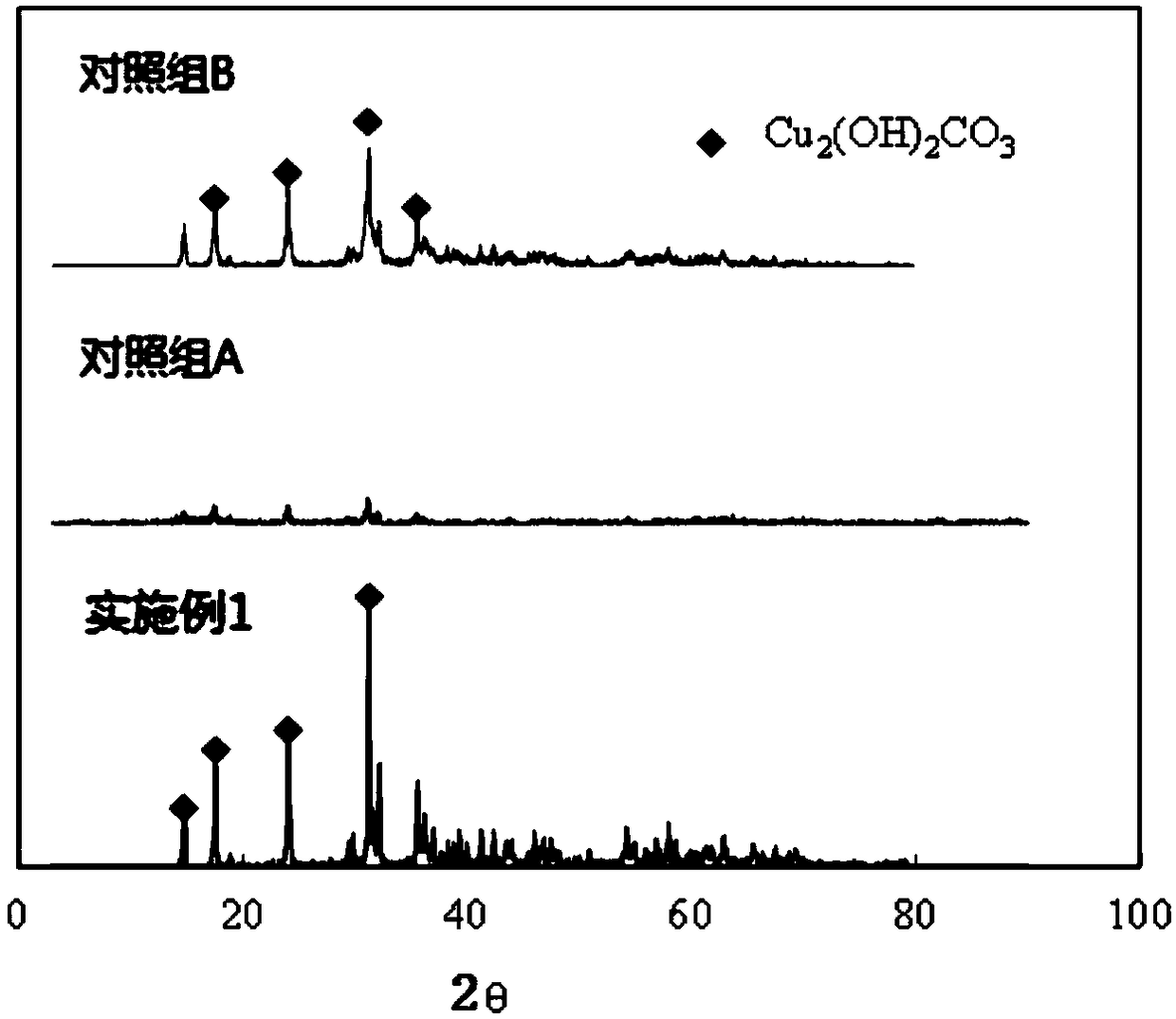

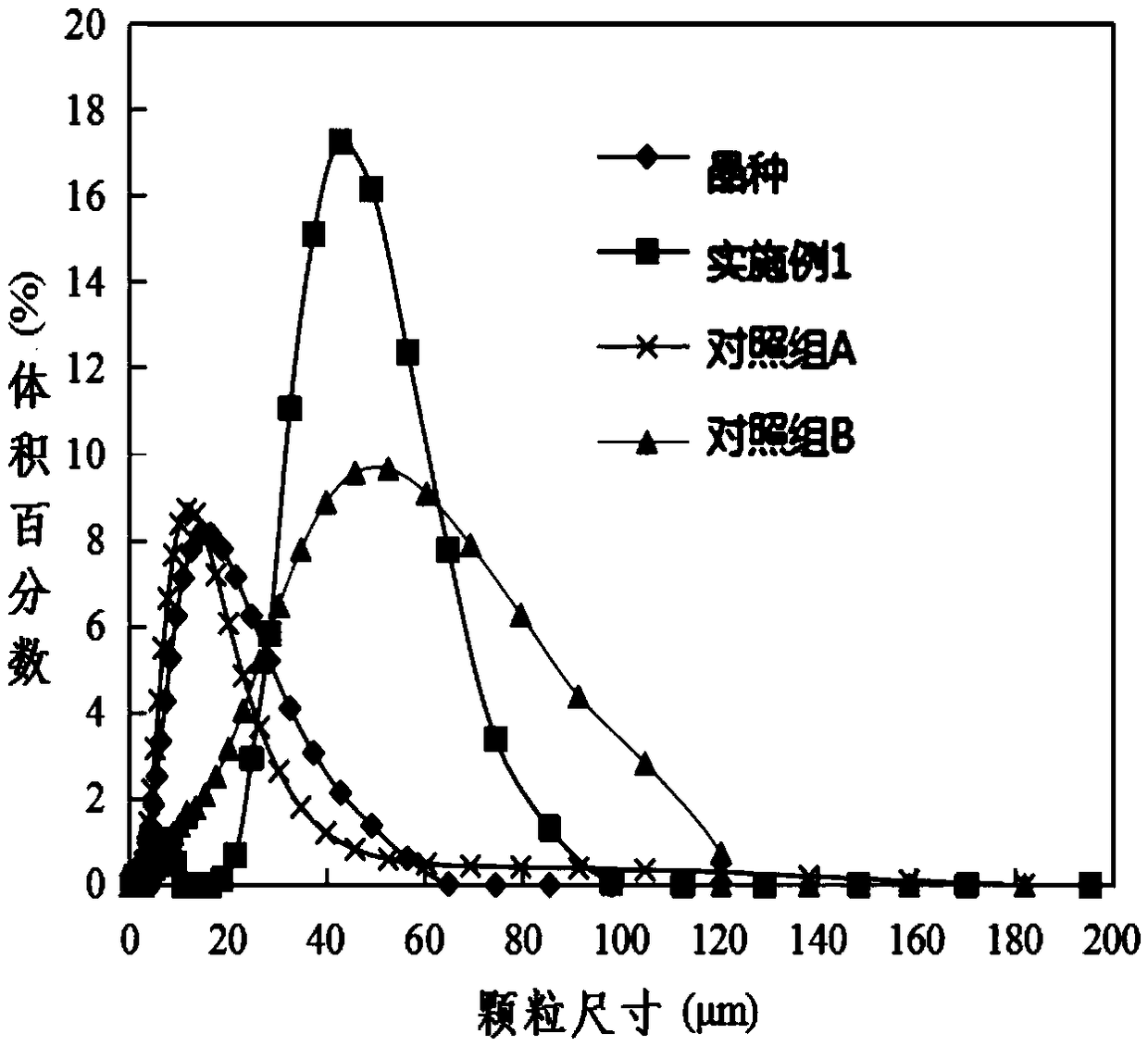

The invention discloses a method for selectively removing and recovering copper in water by using a membrane-assisted crystallization process, and the process is composed of two crystallization reactors which are operated in series and a membrane reactor. In order to ensure the purity of a precipitate and facilitate recovery and reutilization of Cu < 2 + >, Na2CO3 and Cu2(OH)CO3 are used as a precipitant and a seed crystal respectively (only 0.1-0.5wt% is added once at startup). Nucleation and crystal growth the Cu < 2 + > in the water mainly occur in the crystallization reaction. A membrane module in a membrane separator is mainly used for further crystallization and solid phase concentration. Under optimal process conditions, the Cu < 2 + > in the water is finally recycled in the form ofCu2(OH)CO3 crystal particles, and the purity is as high as 99%. Two key parameters of the operation of the process are: supersaturation index (SI <3.22) and excess carbonate (35mg / L <CO3<2-> <50mg / L), and the dosing amount of the precipitant can be adjusted according to effluent water quality requirements, so that the method has the advantages of saving resources and reducing costs, and has positive significance for promoting sustainable development of society.

Owner:TIANJIN UNIV

Method for producing compound containing zinc by utilizing raw ore containing zinc

InactiveCN108950239ARealize economic and environmental protection utilizationEfficient extractionZinc oxides/hydroxidesProcess efficiency improvementDistillationDigestion

The method relates to a method for producing a compound containing zinc by utilizing raw ore containing zinc. The method comprises the steps of digestion, optional purification, decarbonization, calcium zincate compounding, optional rinsing and calcination. According to the method for producing the compound containing zinc by utilizing the raw ore containing zinc, hydrometallurgical leaching is combined with a compounding technology; economical and environmentally-friendly utilization of ultralow-grade zinc ore is achieved; the application range is wide; ammonia distillation is not needed; themethod is simple and easy to be implemented; technological energy consumption is lowered greatly; multi-aspect problems such as water treatment pressure caused by ammonia distillation, potential safety hazards of high temperature and high pressure, equipment corrosion and the like are also avoided; the environmental problem confronted that technological water balance is influenced by surplus water volume brought in by the steam in ammonia circulation technology is solved; the problems with technology recovery rate and quality grade are solved; pollution is little; auxiliary materials can be recycled; compounding of calcium zincate in a zinc-ammonia environment is achieved for the first time; and the compound containing zinc is acquired via calcium zincate.

Owner:CHONGQING DONGQUN TECH CO LTD

Beneficiation method for low-grade raw ore containing zinc

InactiveCN108950238ARealize economic and environmental protection utilizationEfficient extractionZinc oxides/hydroxidesProcess efficiency improvementDistillationDigestion

The invention relates to a beneficiation method for low-grade raw ore containing zinc. The method comprises the steps of digestion, sediment, calcium zincate compounding and calcination. According tothe beneficiation method for the low-grade raw ore containing zinc, economical and environmentally-friendly utilization of ultralow-grade zinc ore is achieved; the application range is wide; ammonia distillation is not needed; the method is simple and easy to be implemented; technological energy consumption is lowered greatly; the problems with technology recovery rate and quality grade are solved; the deficiency of the technological process that secondary treatment is needed to be conducted on raw materials after sulfidizing is solved; pollution is little; auxiliary materials can be recycled;and the problem of environmental pollution brought about by auxiliary raw materials of existing zinc oxide treatment technology is solved. By means of the method, compounding of calcium zincate in azinc-ammonia environment is achieved for the first time.

Owner:CHONGQING DONGQUN TECH CO LTD

Method for synchronously separating and extracting scattered element tellurium and metal copper from cuprous telluride slag

ActiveCN113337724AEfficient selective leachingSimple equipmentProcess efficiency improvementSelenium/tellurium oxides/hydroxidesLeaching (metallurgy)Copper oxide

The invention discloses a method for synchronously separating and extracting a scattered element tellurium and metal copper from cuprous telluride slag, and belongs to the field of nonferrous metallurgy. According to the method, a chlorine-containing composite oxidizing agent is added into an alkaline system to conduct selective oxidation leaching on tellurium in the cuprous telluride slag, the main components of the leaching slag are copper oxide and cuprous oxide, and the leaching slag can be returned to a copper smelting system to recycle metal copper; and the pH value of the tellurium-containing leachate is adjusted by using inorganic acid to precipitate and recover tellurium in the form of TeO2, thereby realizing synchronous separation and extraction of tellurium and copper. The chlorine-containing composite oxidizing agent is adopted for alkaline leaching of the cuprous telluride slag to separate and recover tellurium and copper, the method has the advantages of being high in tellurium and copper recovery rate, simple in process, low in cost and the like, and short-process efficient comprehensive recovery of the cuprous telluride slag can be achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for producing nano zinc oxide by utilizing leaching residues of zincic acid electrolysis method

ActiveCN108862369ARealize secondary useSolve environmental problemsCarbon compoundsZinc oxides/hydroxidesEnvironmental resistanceElectrolysis

The invention relates to a method for producing nano zinc oxide by utilizing leaching residues of a zincic acid electrolysis method. The method comprises a primary extraction step, an optional purification step, a desulfurization step, a calcium zincate synthesis step, a primary calcination step, a secondary extraction step, a pressurizing and crystallization step, a decompression and decomposition step, an optional rinsing step and a secondary calcination step. According to the method disclosed by the invention, secondary utilization of the leaching residues is realized when environmental protection problems are solved; resource utilization is realized when various types of heavy metal pollution are solved; sulfate ions which are considered as a pollution source are changed into valuablethings through calcium sulfate transformation; the synthesis of the calcium zincate under a zinc-ammonia environment is realized for the first time; the nano zinc oxide is obtained through the calciumzincate; ammonia steaming is not needed and the method is simple and feasible; the energy consumption of a technology is greatly reduced; high-temperature and high-pressure potential safety hazards and equipment corrosion problems, which are caused by the ammonia steaming, are also avoided; decomposition conditions of ammonium carbonate are creatively utilized in the technology and cyclic utilization of carbon dioxide is realized through pressure difference.

Owner:CHONGQING DONGQUN TECH CO LTD

Method for producing nano zinc oxide by utilizing zinc-containing raw ores

InactiveCN108793227ARealize economic and environmental protection utilizationEfficient extractionMaterial nanotechnologyZinc oxides/hydroxidesHigh pressureWater balance

The invention relates to a method for producing nano zinc oxide by utilizing zinc-containing raw ores. The method comprises: an extraction step, a random purification step, a decarbonization step, a barium zincate synthesis step, a random rinsing step, a calcination and a barium-zinc separation step. The method disclosed by the invention combines a wet-process leaching technology and a synthesis technology, and economical and environment-friendly utilization of ultralow-grade zinc ores is realized; the method has a wide applicable range, does not need to steam ammonia and is simple and feasible; the energy consumption of the technology is greatly reduced, and the problems in a plurality of aspects of water treatment pressure caused by ammonia steaming, high-temperature and high-pressure potential safety hazards, equipment corrosion and the like are also avoided; the environment protection problem caused by the fact that the surplus water amount carried by steam to influence the technological level in an ammonia circulation technology is solved; the problems of the technological precision and the grade of competitive products are solved; the pollution is small and auxiliary materials can be recycled; the synthesis of barium zincate under a zinc-ammonia environment is realized for the first time and a nano zinc oxide product is produced by barium zincate.

Owner:CHONGQING DONGQUN TECH CO LTD

Method for preparing nano calcium zincate from zinc-containing raw ores

InactiveCN108585026ARealize economic and environmental protection utilizationWide range of applicationsMaterial nanotechnologyZinc compoundsWater balanceDigestion

The invention relates to a method for preparing nano calcium zincate from zinc-containing raw ores. The method comprises the steps of digestion, optional purification, carbon removal, calcium zincatesynthesis, optional rinsing and drying. The method combines wet-process leaching and the synthesis technology, ultralow grade zinc ore economical and environment-friendly utilization can be achieved,the application range is wide, no ammonia distillation is needed, the method is easy and convenient to implement, the energy consumption of the technology is greatly lowered, water treatment pressurecaused by ammonia distillation, high-temperature and high-pressure potential safety hazards, equipment corrosion and other problems are further avoided, the environment-friendly problem that the balance of process water is affected due to the fact that steam is brought into remaining water in the ammonia circulation technology is solved, the purposes of high technology recycling rate and high quality good level are achieved, contaminations are low, auxiliary materials can be recycled, and synthesis of nano calcium zincate under the zinc ammonia environment is achieved for the first time.

Owner:CHONGQING DONGQUN TECH CO LTD

Method for preparing zinc oxide by using zinc-contained raw ores

InactiveCN108913887ARealize economic and environmental protection utilizationEfficient extractionProcess efficiency improvementDecompositionEvaporation

The invention relates to a method for preparing zinc oxide by using zinc-contained raw ores. The method comprises a primary leaching step, an optional purifying step, a decarbonization step, a calciumzincate synthesis step, a primary calcining step, a secondary leaching step, a pressing crystallization step, a decompression decomposing step, an optional rinsing step and a secondary calcining step. The method combines wet leaching with the synthesis process, so that the economical and environment-friendly utilization of low-grade zinc ores is realized, the application range is wide, the ammonia evaporation is not needed, both convenience and feasibility are achieved, the energy consumption of the process is greatly reduced, the high-temperature and high-pressure potential safety hazards and the equipment corrosion problem caused by the ammonia evaporation are prevented, the process recovery rate and the finish product grade problem are solved, and the pollution is low; auxiliary materials can be recycled; the synthesis of calcium zincate under a zinc ammonia environment is realized for the first time; zinc oxide products are prepared by calcium zincate; the decomposition conditionsof ammonia carbonate are creatively used; and the recycling of carbon dioxide is realized through pressure difference.

Owner:CHONGQING DONGQUN TECH CO LTD

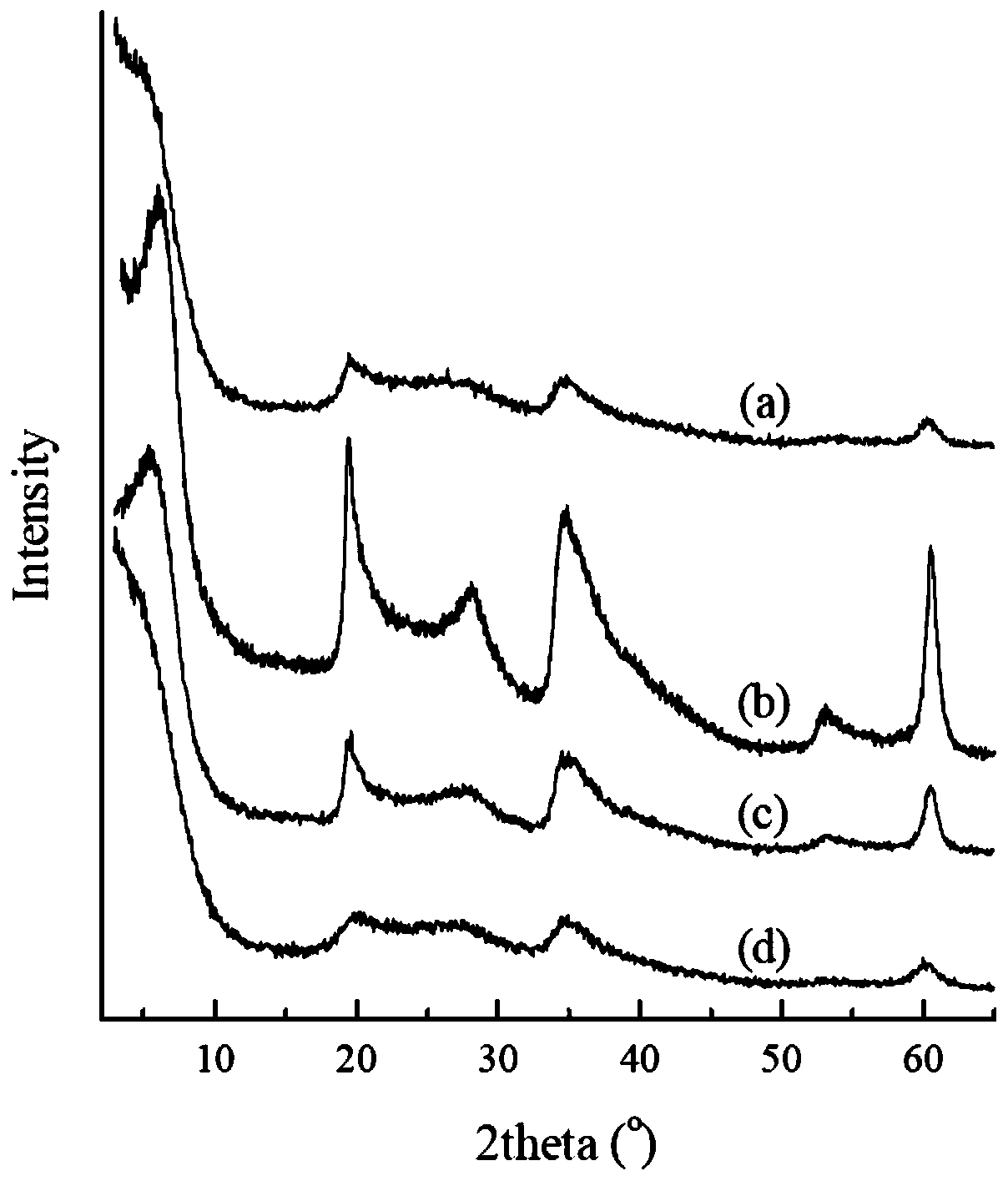

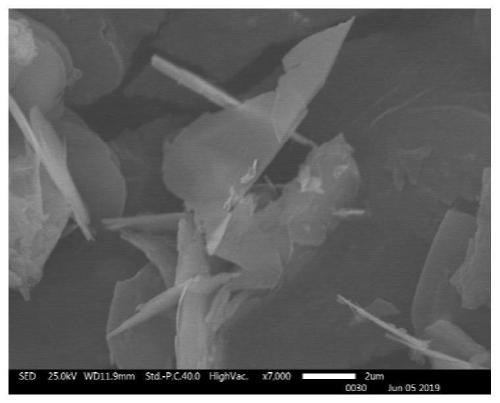

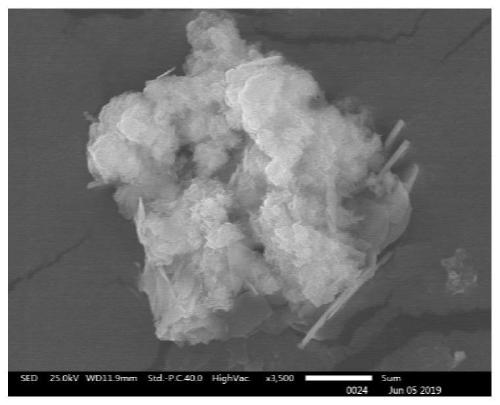

A preparation method of three-dimensional porous graphene-supported nano-magnesium-aluminum hydrotalcite defluoridation agent

ActiveCN103769048BAvoid churnImprove the effect of adsorption treatmentOther chemical processesAlkali metal oxides/hydroxidesPorous grapheneCarboxylic acid

The invention discloses a preparation method of a three-dimensional porous graphene-loaded nanometer magnesium-aluminum hydrotalcite fluorine removal agent. The preparation method comprises the following steps: (a) preparing the three-dimensional porous graphene; (b) preparing magnesium-aluminum solution, immersing the three-dimensional porous graphene in the solution; and (c) separating the immersed three-dimensional porous graphene, drying in a vacuum condition, adding into a carbon source weak base dilute solution, reacting, standing, aging, filtering, washing, and drying, so as to obtain the three-dimensional porous graphene-loaded nanometer magnesium-aluminum hydrotalcite fluorine removal agent. Due to the adoption of the method, the agglomeration characteristic of the magnesium-aluminum hydrotalcite prepared by a traditional method is overcome, the specific surface area of the nanometer magnesium-aluminum hydrotalcite is improved; meanwhile, because the carboxylic groups in the three-dimensional porous graphene are combined with the magnesium-aluminum atoms, the nanometer particles can be effectively limited into a porous channel of the three-dimensional porous graphene, losing of the nanometer material is avoided in a using process, and the material has a significant effect in fluorine-containing water treatment.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

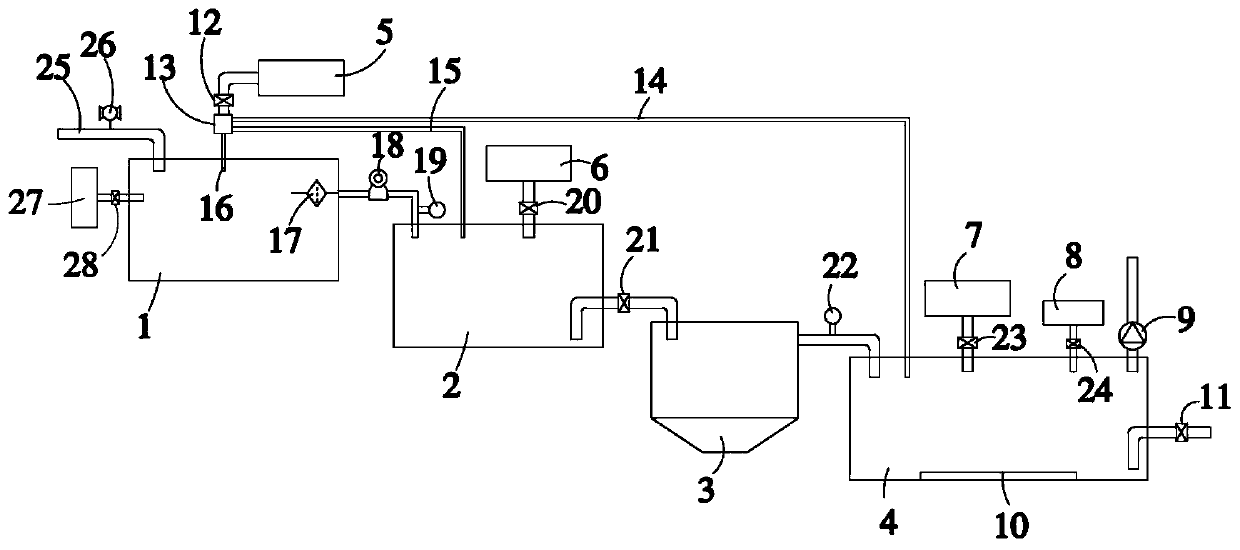

Recycling multi-stage comprehensive treatment method and equipment for fluorine-containing wastewater

InactiveCN109987801AMeet emission standardsAchieve removalMagnesium fluoridesWater treatment parameter controlActivated sludgeEmission standard

The invention discloses a recycling multi-stage comprehensive treatment method and equipment for fluorine-containing wastewater. The method comprises the following steps: (1) adjusting the pH value offluorine-containing wastewater to 5-6, adding a metal chelating agent, and optimizing the total concentration of heavy metal ions to be less than or equal to 1.5 mg / L; (2) adjusting the pH value to 8-9, adding magnesium trisilicate according to an adding amount of 0.2-0.4 g / L, then adding magnesium chloride to enable [Mg<2+>] / [F<->] to be 1.2-1.8, and rapidly carrying out stirring for 3-6 hours to form magnesium fluoride with magnesium trisilicate as a crystal nucleus; (3) carrying out biochemical treatment, namely adjusting the pH value to 6-7, adding activated sludge according to an addingamount of 1-5 g / L, and carrying out continuous aeration treatment at a temperature of 25 DEG C until the concentration of chemical oxygen demand (COD) of the effluent is less than or equal to 100 mg / Land the ratio of biochemical oxygen demand (BOD) to COD is greater than or equal to 0.3; and (4) adding a composite flocculant into the obtained treatment liquid according to an adding amount of 5-7g / L, carrying out standing overnight, and carrying out solid-liquid separation to enable the concentration of F<-> in the effluent to be smaller than or equal to 7.5 mg / L and the concentration of suspended solids (SS) in the effluent to be less than or equal to 150 mg / L. According invention, multistage comprehensive treatment is carried out on the fluorine-containing wastewater through combinationof treatment methods such as a chemical precipitation method, a coagulation precipitation method and a biochemical method, so that the treated wastewater reaches the emission standard, purity of theMgF2 product is improved, and recycling of the fluorine-containing wastewater is realized.

Owner:BENGBU COLLEGE

A kind of method utilizing electrolytic zinc acid leaching residue to produce zinc oxide

ActiveCN108950225BRealize secondary useSolve environmental problemsProcess efficiency improvementSulfate radicalsZincate

The invention relates to a method for producing zinc oxide through electrolytic zinc acid process leaching residues. The method comprises a primary digestion step, an optional purifying step, a desulfuration step, a calcium zincate synthesizing step, a primary calcining step, a secondary digestion step, a pressurizing and crystallizing step, a pressure reducing and decomposing step, an optional rinsing step and a secondary calcining step. According to the method, the problem about environmental protection is solved, secondary utilization of the leaching residues is achieved, pollution of multiple heavy metals is avoided, and meanwhile resource utilization of the leaching residues is achieved. Ammonia distillation is not needed, the method is simple, convenient and practical, and the energyconsumption of the process is greatly reduced. Sulfate ions as a pollution source are converted into wealth from waste through calcium sulfate, calcium zincate synthesis is achieved in a zinc ammoniaenvironment for the first time, zinc oxide is obtained from calcium zincate, the decomposing condition of ammonium carbonate is creatively utilized in the process, and recycling of carbon dioxide isachieved through differential pressure.

Owner:CHONGQING DONGQUN TECH CO LTD

A method for producing nanometer zinc oxide by using electrolytic zinc acid leaching slag

ActiveCN108862369BRealize secondary useSolve environmental problemsCarbon compoundsZinc oxides/hydroxidesElectrolysisSulfate radicals

Owner:CHONGQING DONGQUN TECH CO LTD

A preparation method for photodegradable organic toxic gas multilevel nanocomposite material

ActiveCN109821524BAchieve enrichmentUniform void distributionPhysical/chemical process catalystsDispersed particle separationGlycerolNanocomposite

The invention discloses a method for preparing a multi-stage nanocomposite material with photodegradable organic toxic gas, which comprises the preparation of porous layered nano-montmorillonite: the montmorillonite is pulverized to an average particle size of 50 to 50 by mechanical pulverization and air flow method. 200nm; preliminary preparation of nanocomposite materials: compound the montmorillonite and titanium-based photocatalyst materials at low temperature to obtain a compound, add the compound to water or alcohol, react at low temperature, and then add nitrogen source or carbon source for reaction , to obtain the primary nanocomposite material; multi-level nanocomposite material modification: after the primary nanocomposite material is cooled down, a modifier is added for modification, and the modifier accounts for the compound / water or alcohol / nitrogen source or carbon source 0.2-2% of the total mass of the system; the modifying agent includes glycerol or triethanolamine.

Owner:南京森之语新材料科技有限公司

A method for utilizing zinc-containing raw ore by strontium zincate synthesis step

ActiveCN110228816BAchieve synthesisHigh selectivityZinc compoundsProcess efficiency improvementPhysical chemistryZinc

The present disclosure relates to a process for utilizing zinc-containing ore through a strontium zincate synthesis step, comprising a leaching step, an optional purification step, a decarburization step, a strontium zincate synthesis step, an optional rinsing step, and a drying or calcination step. The present disclosure realizes the synthesis of strontium zincate in the environment of zinc ammonia for the first time, and the reaction selectivity of synthesizing strontium zincate from zinc ammonium complex ions is high, simple and fast, and high value-added products are economically and environmentally friendly prepared from low-grade raw ores that are difficult to handle The disclosed method has a wide range of applications, can effectively extract and utilize various forms of zinc-containing raw ores, enriches zinc elements through the synthesis of strontium zincate, solves the problems of process recovery and high-quality goods grade, and the obtained products can be As a product directly, it can also be used as an industrial raw material.

Owner:CHONGQING DONGQUN TECH CO LTD

Preparing method of light-degraded organic poisonous gas multi-stage nanometer composite

ActiveCN109821524AAchieve enrichmentUniform void distributionPhysical/chemical process catalystsDispersed particle separationAlcoholGlycerol

The invention discloses a preparing method of a light-degraded organic poisonous gas multi-stage nanometer composite. The preparing method includes the steps of preparing porous lamellar nanometer montmorillonite, smashing the montmorillonite through a mechanical smashing method and a gas flow method until the average particle size is 50-200 nm, primarily preparing the nanometer composite, compounding the montmorillonite and a titanium-series photocatalysis material at a low temperature to obtain a compound, adding the compound to water or alcohol for low-temperature reaction, adding a nitrogen source or carbon source for reaction to obtain a primary nanometer composite, modifying the multi-stage nanometer composite, cooling the primary nanometer composite, and then adding a modifier for modifying the composite, wherein the modifier accounts for 0.2-2% of the total mass of the compound, the water or alcohol and the nitrogen source or carbon source, and the modifier comprises glycerol or triethanolamine.

Owner:南京森之语新材料科技有限公司

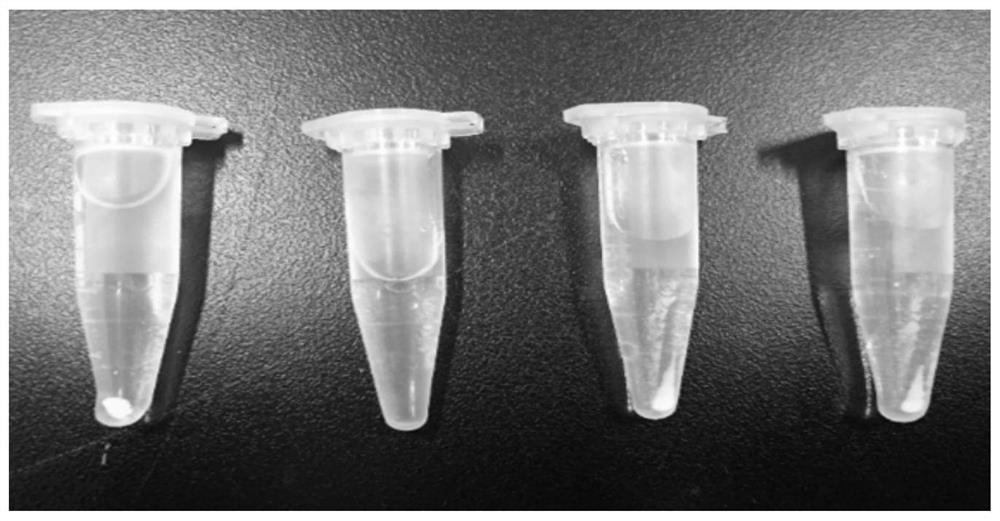

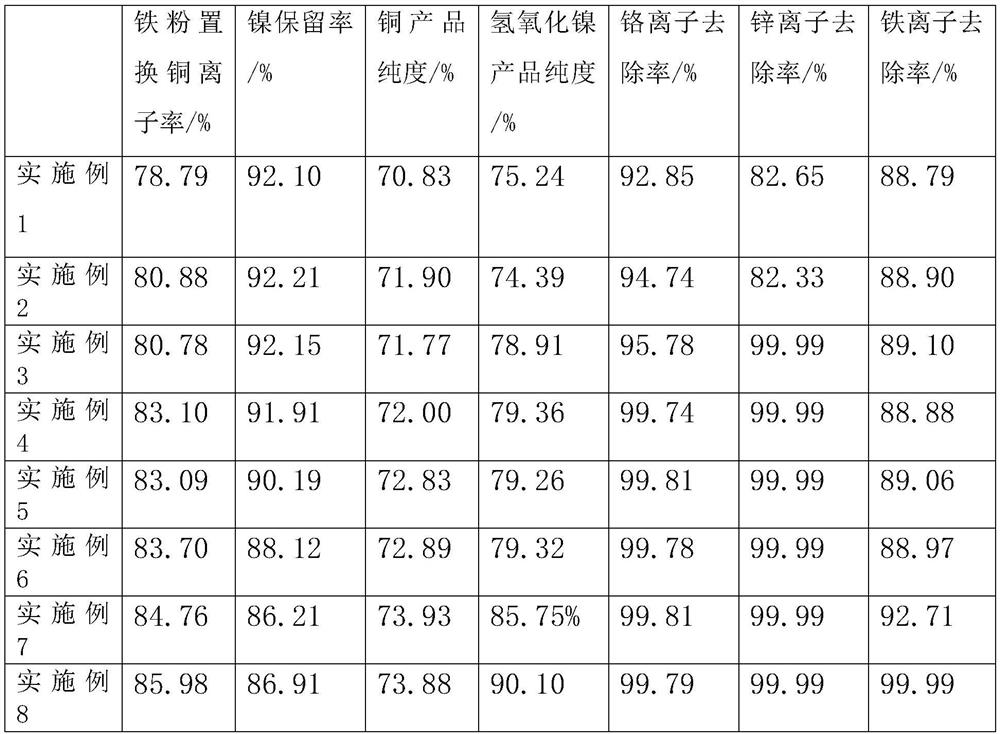

Resource recycling method for electroplating sludge with high copper and nickel content

InactiveCN113249579ANo lossEfficient separationProcess efficiency improvementNickel oxides/hydroxidesIron powderSludge

The invention particularly discloses a resource recycling method for electroplating sludge with high copper and nickel content. The resource recycling method for electroplating sludge with high copper and nickel content comprises the following preparation steps: S1, acid dissolving and leaching; S2, replacing metal copper with iron powder: adding the iron powder into a filtrate 1, controlling pH to be 0-0.5, after reacting for 2 hours, filtering to respectively obtain an insoluble solid and a filtrate 2, and washing the insoluble solid with water, desalting and airing to obtain a copper product; S3, impurity removal of sulfide; S4, removing iron and chromium by an oxidation and hydroxide method: after oxidation, adding hydroxide, adjusting pH to 5.0-6.0, reacting for 1.5 hours, and filtering insoluble impurities to obtain a filtrate 3; and S5, a process of preparing nickel hydroxide by using a hydroxide compound, namely adding hydroxide into the filtrate 3, adjusting pH to 9.0-10.0, reacting for 0.5 hour, filtering to obtain an insoluble solid, and drying the insoluble solid to obtain the nickel hydroxide. According to the resource recycling method for the electroplating sludge with the high copper and nickel content, the product copper and the product nickel hydroxide can be recycled, and the yield and the purity of the product copper and the nickel hydroxide are improved.

Owner:厦门晖鸿环境资源科技有限公司

Beneficiation method for low-grade zinc-containing raw ores

InactiveCN108998664ARealize economic and environmental protection utilizationEfficient extractionProcess efficiency improvementZincateDistillation

The invention relates to a beneficiation method for low-grade zinc-containing raw ores. The method comprises the steps of leaching, decarbonization, calcium zincate synthesis, and drying. The method disclosed by the invention has the advantages that wet leaching is combined with a beneficiation technique, so that ultralow-grade zinc ores can be utilized in an economical and environment-friendly manner, the application range is wide, ammonia distillation is not required, high simplicity and convenience are achieved, the problems of a low recovery rate and a low concentrate grade of the beneficiation technique are solved, and the defect that vulcanized raw materials need to go through a secondary treatment process is overcome; the pollution is low, and supplemental materials are recyclable,so that the problem of environmental pollution caused by supplemental raw materials in the conventional zinc oxide treatment process is solved; and the calcium zincate synthesis under a zinc-ammonia environment is achieved for the first time.

Owner:CHONGQING DONGQUN TECH CO LTD

Method for producing zinc-containing complex or zinc oxide using zinc-containing raw ore via intermediate step for synthesis of calcium zincate

ActiveCN110896643AAchieve synthesisHigh selectivityZinc oxides/hydroxidesProcess efficiency improvementZincatePhysical chemistry

Disclosed is a method for producing a zinc-containing complex or zinc oxide using a zinc-containing raw ore via an intermediate step for the synthesis of calcium zincate. The method for producing a zinc-containing complex using a zinc-containing raw ore via an intermediate step for the synthesis of calcium zincate comprises an extraction step, an optional purification step, a decarburization and precipitation step, a calcium zincate synthesis step, an optional rinsing step and a calcination step; and the method for producing zinc oxide using a zinc-containing raw ore via an intermediate step for the synthesis of calcium zincate comprises an extraction step, an optional purification step, a decarburization and precipitation step, a calcium zincate synthesis step, an optional rinsing step, acalcination step and a calcium-zinc separation step.

Owner:CHONGQING DONGQUN TECH CO LTD

Method for utilizing zinc-containing raw ore through strontium zincate synthesis step

ActiveCN110228816AAchieve synthesisHigh selectivityZinc compoundsProcess efficiency improvementZincateStrontium

The invention relates to a method for utilizing zinc-containing raw ore through the strontium zincate synthesis step, comprising the following steps: leaching, optional purification, decarburization,strontium zincate synthesis, optional rinsing, drying or calcining. The invention realizes the synthesis of strontium zincate in a zinc ammonia environment; the reaction selectivity for synthesis of strontium zincate from zinc ammonia complex-ions is high, and the synthesis is simple and fast; and the high added-value product is prepared economically and environmentally from the low-grade raw orewhich is hard to deal with. The method of the invention has a wide range of application, and can effectively extract and utilize various forms of zinc-containing raw ore and enrich the zinc element through the strontium zincate synthesis route, thereby solving problems of process recovery rate and quality product grade. The product obtained by the method can be directly used as a product, and alsocan be used as an industrial raw material.

Owner:CHONGQING DONGQUN TECH CO LTD

A kind of preparation method of high-purity magnesium saponite

ActiveCN109626386BPromote formationOptimizing growing conditionsSilicon compoundsSodium bicarbonateIonic strength

The invention discloses a preparation method of high-purity magnesium saponite. The preparation method includes the steps that deionized water, water glass and sodium hydroxide are mixed and preparedinto a silicon-containing water solution; deionized water and magnesium salt are mixed and prepared into a magnesium-containing water solution; deionized water, aluminum salt, potassium salt, sodium hydroxide and sodium bicarbonate are mixed and prepared into an aluminum-containing water solution; under stirring conditions, the magnesium-containing water solution and the aluminum-containing watersolution are mixed firstly, so that mixed liquor is obtained; then the silicon-containing water solution is added into the mixed liquor, so that crystallizing liquor is obtained; the obtained crystallizing liquor is added into a crystallizing kettle for constant-temperature crystallization, then a mixture is cooled to have room temperature, and through centrifuging, washing, drying, smashing and sieving, the magnesium saponite is obtained. Under synergism of ion strength of a strong electrolyte solution, hydroxyl ions and carbonate ions, the alkalinity of the crystallizing liquor and the concentration of non-structure crystal ions are adjusted, the orienteering rate and clustering rate of structure crystal ions are coordinated, forming of a saponite crystal nucleus and crystal nucleus growth conditions are optimized, co-precipitation and after-precipitation are avoided, the purity of crystals is improved, and impurity forming is reduced.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

Method for producing zinc-containing compound or zinc oxide by using zinc-containing raw ore through calcium zincate synthesis intermediate step

ActiveCN110896643BAchieve synthesisHigh selectivityZinc oxides/hydroxidesProcess efficiency improvementChemical synthesisZincate

A method for producing a zinc-containing compound or zinc oxide through an intermediate step of calcium zincate synthesis using a zinc-containing raw ore, the method for producing a zinc-containing compound through a zinc-containing raw ore through an intermediate step of calcium zincate synthesis includes an extraction step, an optional Purification step, decarburization precipitation step, calcium zincate synthesis step, optional rinsing step, calcining step; the method for producing zinc oxide through the intermediate steps of calcium zincate synthesis using zinc-containing raw ore includes a leaching step, an optional purification step, Decarburization precipitation step, calcium zincate synthesis step, optional rinsing step, calcining step, calcium zinc separation step.

Owner:CHONGQING DONGQUN TECH CO LTD

Method for purifying phosphoric acid raffinate and recovering magnesium ammonium phosphate hexahydrate

ActiveCN110371944AHigh purityAvoid inclusionsChemical industryPhosphorus compoundsRoom temperaturePhosphoric acid

The invention relates to a method for purifying phosphoric acid raffinate and recovering magnesium ammonium phosphate hexahydrate. According to the technical scheme, the method for purifying the phosphoric acid raffinate and recovering the magnesium ammonium phosphate hexahydrate comprises the steps that, water is added to the phosphoric acid raffinate according to the mass ratio of the phosphoricacid raffinate to water of 1 to (0.1-0.3), the mixture is stirred at room temperature for 0.5-1h, and the diluted phosphoric acid raffinate is obtained; and urea is added to the diluted phosphoric acid raffinate according to the mass ratio of the urea to the diluted phosphoric acid raffinate of (0.5-2) to1, the mixture is stirred at a temperature of 70-100 DEG C until a pH value is 5-6, the mixture is cooled, subjected to solid-liquid separation and washed to obtain iron-removing aluminum liquid and an iron-containing aluminum residue; and then the iron-removing aluminum liquid is stirred at70-100 DEG C until a pH value is 6-7, the iron-removing aluminum liquid is cooled, subjected to solid-liquid separation and washed to obtain a phosphoric acid raffinate purifying solution and the magnesium ammonium phosphate hexahydrate. The method for purifying the phosphoric acid raffinate and recovering the magnesium ammonium phosphate hexahydrate has the characteristics of short process flow,small phosphorus loss and easy recycling of metal ions.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com