Recycling multi-stage comprehensive treatment method and equipment for fluorine-containing wastewater

A comprehensive treatment and recycling technology, which is applied in the field of multi-level comprehensive treatment of recycling, can solve the problems of incomplete defluorination, low fluorine content, and high difficulty in recycling, and achieve resource recycling, low water content, and easy cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

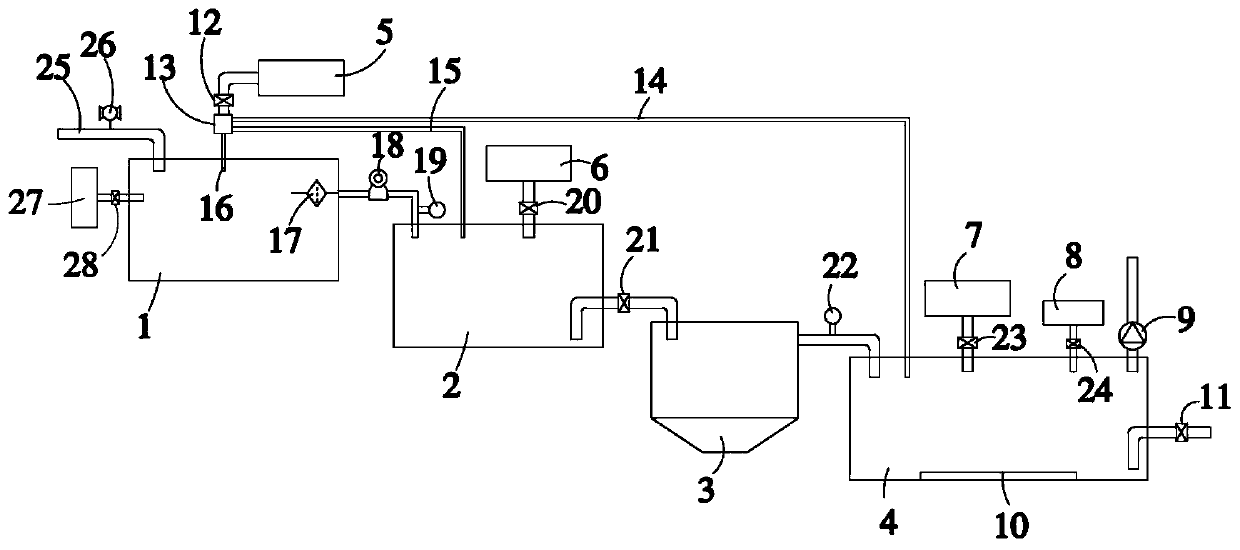

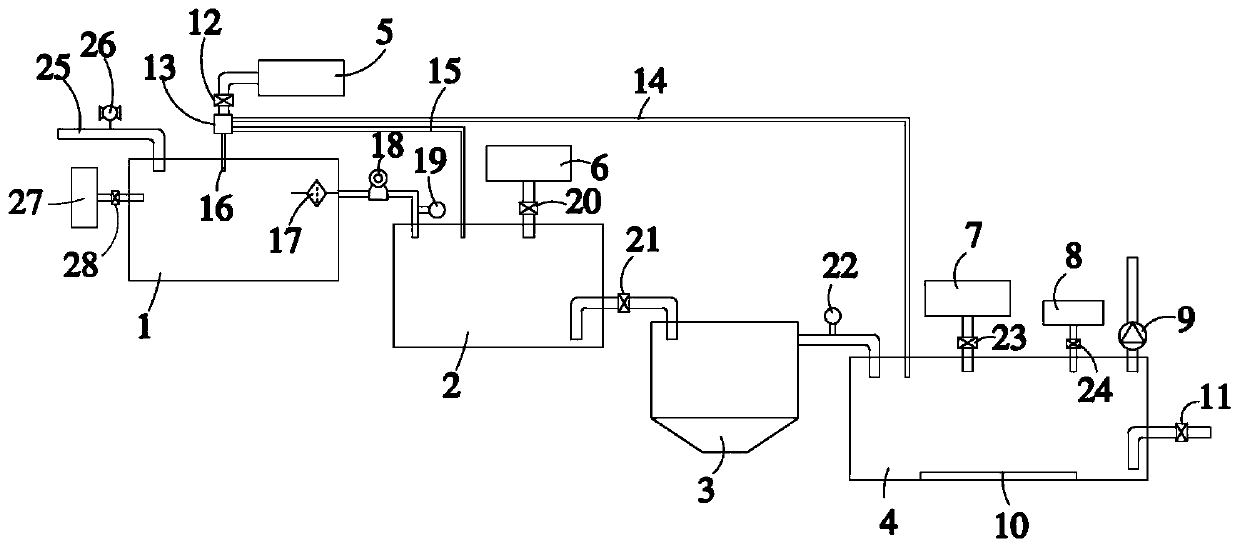

Image

Examples

Embodiment 1

[0030] A resource-based multistage treatment method for fluorine-containing wastewater, wherein F in the fluoride-containing wastewater - Concentration≧1500mg / L, SS≧600mg / L, COD≧1000mg / L, BOD / COD≦0.1, heavy metal ion concentration≧25mg / L, the heavy metal ion includes Ag + 、Cu 2+ 、Co 3+ 、Ni 3+ ;

[0031] The resource-based multi-level processing method specifically includes the following steps:

[0032] (1) Precipitation and impurity removal: adjust the pH of fluorine-containing wastewater to 5, then add glucono-δ-lactone, optimize the total concentration of heavy metal ions ≦1.5mg / L, and filter to remove sediment;

[0033] (2) Prepare magnesium fluoride with magnesium trisilicate as the crystal nucleus: adjust the pH of the fluorine-containing wastewater filtrate obtained in step (1) to 8, and add magnesium trisilicate with a particle size of 0.01 μm at a dosage of 0.2 g / L, After stirring evenly, add magnesium chloride again, make [Mg2+ ] / [F - ] was 1.2, stirred rapidly ...

Embodiment 2

[0037] Processing method is the same as embodiment 1, difference is:

[0038] (1) Precipitation and impurity removal: adjust the pH of fluorine-containing wastewater to 5.5, and the metal chelating agent used is sodium hexametaphosphate;

[0039] (2) Preparation of magnesium fluoride with magnesium trisilicate as the crystal nucleus: adjust the pH of the fluorine-containing wastewater filtrate obtained in step (1) to 8.5, the particle size of magnesium trisilicate is 0.5 μm, and the dosage is 0.3 g / L, [ Mg 2+ ] / [F - ] was 1.5, stirred rapidly for 5h;

[0040] (3) Biochemical treatment: adjust the pH of the filtrate obtained in step (2) to 6.5, and the dosage of activated sludge is 3g / L;

[0041] (4) Flocculation and impurity removal: The dosage of the composite flocculant is 6g / L.

Embodiment 3

[0043] Processing method is the same as embodiment 1, difference is:

[0044] (1) Precipitation and impurity removal: adjust the pH of fluorine-containing wastewater to 6, and the metal chelating agent used is ethylenediaminetetraacetic acid;

[0045] (2) Preparation of magnesium fluoride with magnesium trisilicate as the crystal nucleus: adjust the pH of the fluorine-containing wastewater filtrate obtained in step (1) to 9, the particle size of magnesium trisilicate is 1 μm, and the dosage is 0.4g / L, [Mg 2+ ] / [F - ] was 1.8, stirred rapidly for 6h;

[0046] (3) Biochemical treatment: adjust the pH of the filtrate obtained in step (2) to 7, and the dosage of activated sludge is 5 / L;

[0047] (4) Flocculation and impurity removal: The dosage of the composite flocculant is 7g / L.

[0048] Adopt embodiment 1-3 method to process fluorine-containing waste water, effluent F - Total concentration≦7.5mg / L, total concentration of heavy metal ions≦1.5mg / L, COD≦100mg / L, BOD / COD≧0.3, S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com