Resource recycling method for electroplating sludge with high copper and nickel content

A recovery method and nickel electroplating technology, applied in the field of high-content copper and nickel electroplating sludge recycling, can solve the problems of incomplete separation, low product purity, single electroplating sludge quality requirements, etc., to avoid co-precipitation and ensure The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

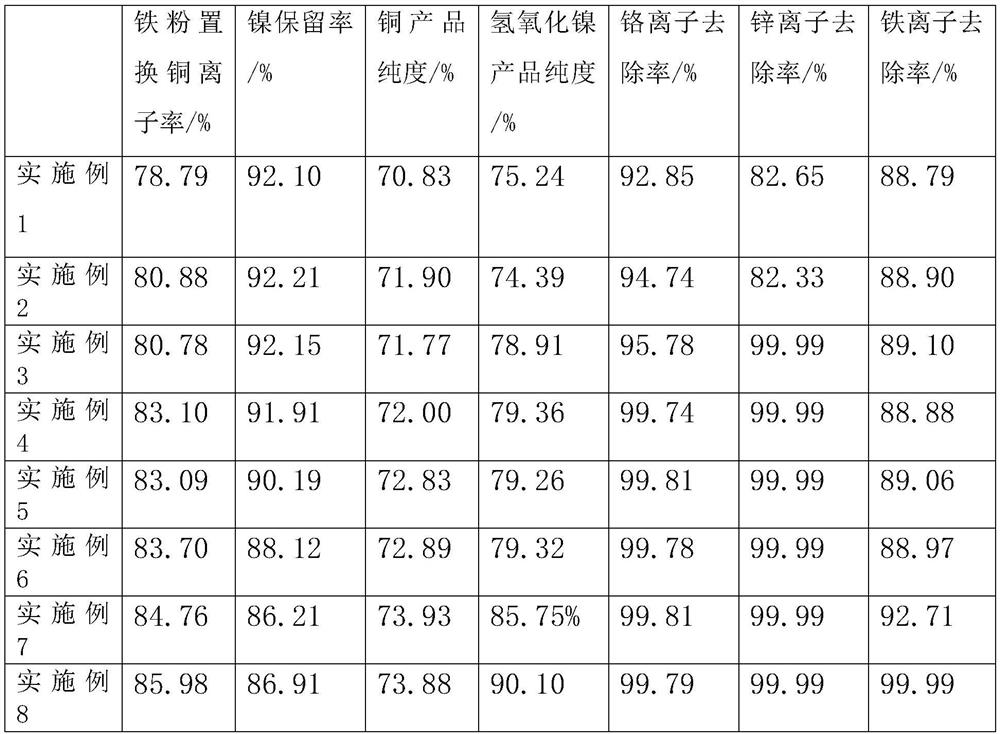

Examples

Embodiment 1

[0038] A method for recycling high-content copper and nickel electroplating sludge, comprising the following preparation steps:

[0039] S1. Substitution of metal copper with iron powder: take 0.2L filtrate, and add 0.1kg iron powder to filtrate 1, control the pH at 0.1, react for 2 hours, obtain insoluble solid and filtrate 2 respectively after filtration, wash the insoluble solid with water, desalt , obtain product copper after drying, wherein, the fineness of iron powder is 1000 μ m;

[0040] S2, sulfide removal: add sodium sulfide to the filtrate 2 until the pH is 1, and react for 0.5h;

[0041] S3. Iron and chromium removal by hydroxide method: add sodium hydroxide, adjust the pH to 5.0, react for 1.5 hours, and filter insoluble impurities to obtain filtrate 3;

[0042] S4. Process for preparing nickel hydroxide by hydroxide compound method: add sodium hydroxide to the filtrate 3, adjust the pH to 9.0, react for 0.5h, filter to obtain insoluble solid and filtrate 4, and ...

Embodiment 2

[0044] A method for recycling high-content copper and nickel electroplating sludge, comprising the following preparation steps:

[0045] S1. Substitution of metal copper with iron powder: take 0.2L filtrate, add 0.11kg iron powder to filtrate 1, control the pH at 0.2, react for 2 hours, obtain insoluble solid and filtrate 2 respectively after filtration, wash the insoluble solid with water, remove salt, Obtain product copper after drying, wherein, the fineness of iron powder is 830 μ m;

[0046] S2, sulfide removal: add sodium sulfide to the filtrate 2 until the pH is 1.2, and react for 0.5h;

[0047] S3. Iron and chromium removal by hydroxide method: add sodium hydroxide, adjust the pH to 5.2, react for 1.5 hours, and filter insoluble impurities to obtain filtrate 3;

[0048] S4. Nickel hydroxide production process by hydroxide compound method: add sodium hydroxide to the filtrate 3, adjust the pH to 9.2, react for 0.5h, filter to obtain insoluble solid and filtrate 4, and d...

Embodiment 3

[0050] S1. Substitution of metal copper with iron powder: take 0.2L filtrate, add 0.12kg iron powder to filtrate 1, control the pH at 0.3, react for 2 hours, obtain insoluble solid and filtrate 2 respectively after filtering, wash the insoluble solid with water, desalt, Obtain product copper after drying, wherein, the fineness of iron powder is 660 μ m;

[0051] S2, sulfide removal: add potassium sulfide to the filtrate 2 until the pH is 1.3, and react for 0.5h;

[0052] S3. Iron and chromium removal by hydroxide method: add potassium hydroxide, adjust the pH to 5.4, react for 1.5 hours, and filter insoluble impurities to obtain filtrate 3;

[0053] S4. Nickel hydroxide production process by hydroxide compound method: add potassium hydroxide to the filtrate 3, adjust the pH to 9.4, react for 0.5h, filter to obtain insoluble solid and filtrate 4, and dry the insoluble solid to obtain nickel hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com