Hydroxylation iron catalyzer, preparation method and application thereof

An iron catalyst and a hydroxylation technology are applied in the field of hydroxylated iron catalyst and its preparation, which can solve the problems of low catalytic activity of the catalyst, secondary pollution by metal ion dissolution, poor stability, etc. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

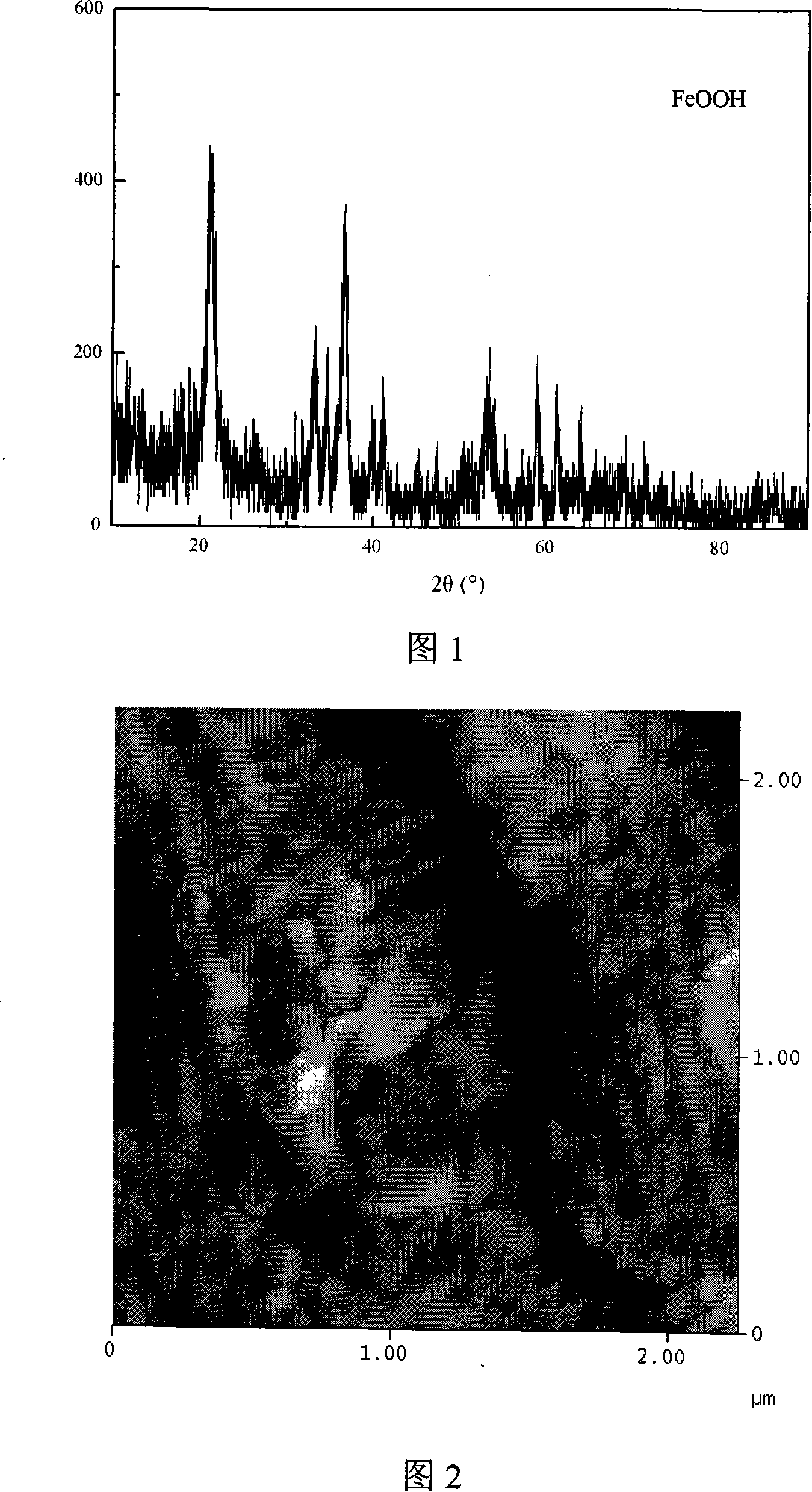

specific Embodiment approach 1

[0012] Specific implementation mode one: the iron hydroxylation catalyst of the present embodiment is formed by soluble ferric salt aqueous solution and alkali solution 3+ with OH - The molar ratio is 1:3~4, which is made by uniform precipitation method, and the soluble ferric salt is FeCl with a volume concentration of 10~40%. 3 , Fe 2 (SO 4 ) 3 , Fe(NO 3 ) 3 or FePO 4 , the alkaline solution is a NaOH or KOH aqueous solution with a volume concentration of 20-50%; its preparation method: 1. prepare a soluble ferric salt solution and an alkaline solution; Add dropwise to the soluble ferric salt aqueous solution to mix and precipitate evenly, the dropping rate is 1-2 drops / s; 3. After the precipitation reaction is completed, adjust the pH of the mixed solution to 12-14, and let it stand for 3-6 hours (the purpose of standing is to Make the precipitation complete); 4. Put the reactant after standing in the incubator, activate it for 12-20h at 70-80°C, and then filter to o...

specific Embodiment approach 2

[0015] Specific embodiment two: the difference between this embodiment and specific embodiment one is that Fe 3+ with OH - The molar ratio is 1:3.2~3.8. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment one is that Fe 3+ with OH - The molar ratio is 1:3.5. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com