A kind of preparation method of alumina carrier

A technology of alumina carrier and acidic aluminum, which is applied in the direction of catalyst carrier, preparation of alkali metal aluminate/alumina/aluminum hydroxide, chemical instruments and methods, etc. Insufficient aluminum carrier, particles and other problems, to achieve the effect of narrow particle size distribution, high crystal purity, and simplified preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of alumina carrier of the present invention specifically comprises the following steps:

[0041] (a) Prepare the working solution, the concentration and preparation method of the working solution are well known to those skilled in the art. For example, the concentration of an acidic aluminum salt solution is Al 2 o 3 It is calculated as 3g / 100mL~15g / 100mL; the concentration of alkali metal aluminate aqueous solution is expressed as Al 2 o 3 It is calculated as 8g / 100mL~35g / 100mL, or dilute ammonia solution can be prepared, the concentration is NH 3 Calculated as 9 g / 100mL ~ 20g / 100mL. Acidic aluminum salt solution is generally AlCl 3 、Al 2 (SO 4 ) 3 or Al(NO) 3 Aqueous solution, preferably Al 2 (SO 4 ) 3 Aqueous solution; The alkali metal aluminate aqueous solution is selected from NaAlO 2 or KAlO 2 aqueous solution. Alkaline precipitants are generally NaOH, (NH 4 ) 2 CO 3 or NH 4 OH solution, preferably (NH 4 ) 2 CO 3 or NH ...

Embodiment 1

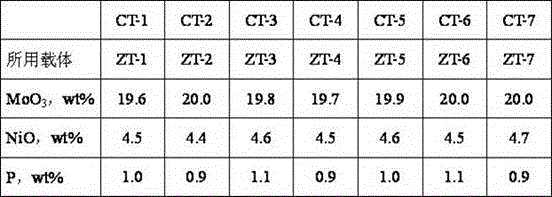

[0054] This example introduces the preparation method of Mo, Ni, P original solution. In this example, only one original solution of Mo, Ni, and P with one concentration and ratio is prepared, and solutions with other ratios and concentrations can be prepared according to the method introduced.

[0055] Take 386g of molybdenum oxide and 123g of basic nickel carbonate into a multi-necked flask, add a certain amount of deionized water, stir until the substance in the bottle is slurry, then slowly add 86g of phosphoric acid, and then heat slowly after the initial reaction , keep the solution temperature at 90° C. to 110° C. for 1 h to 3 h. After stopping the heating, filter the obtained solution while it is hot, and after filtering out some insoluble impurities, a clear dark green original solution is obtained. The solution composition is MoO 3 : 69.27g / 100ml; NiO: 12.49g / 100ml; P: 4.10g / 100ml.

Embodiment 2

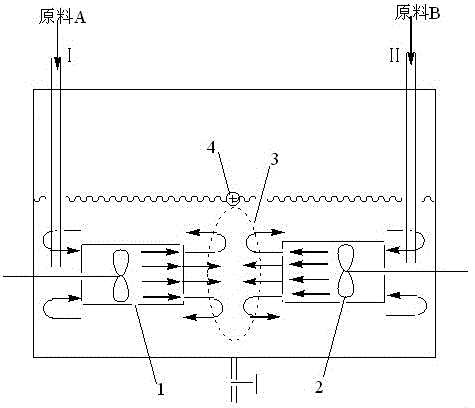

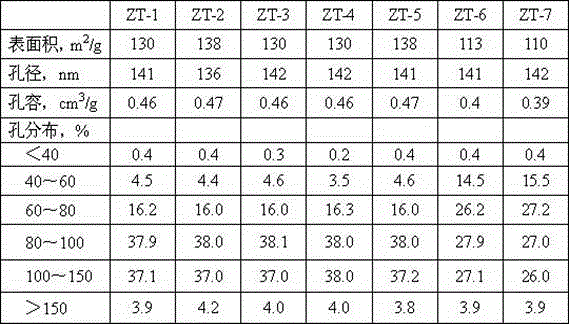

[0057] 6L sodium metaaluminate aqueous solution (Al 2 o 3 The concentration is 20g / 100mL) and 9L aluminum sulfate aqueous solution (Al 2 o 3 Concentration of 5g / 100mL) into containers with pumps, respectively connected to the feed port Ⅰ and feed port Ⅱ of the impingement flow reactor equipped with 5L distilled water, and heat the impingement flow reactor to 65°C ;Start the propeller agitator in the impinging flow reactor, adjust the included angle of the two draft tubes to 0°, adjust the rotating speed to 1500r / min, and after a period of stability, adjust the flow rate of the feed inlet I and the feed inlet II to 0.6L / min, start to inject sodium metaaluminate aqueous solution and aluminum sulfate aqueous solution, adjust the pH value to 7.0; after 15 minutes of neutralization, stop feeding, and after 10 minutes of stabilization; add sodium metaaluminate aqueous solution, adjust the pH value to 9.0, stop Feeding; after 10 minutes of stabilization, add aluminum sulfate aqueo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com